Preparation method of microcrystalline silver powder with hollow structure

A hollow structure and microcrystalline technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of sensitive reaction control conditions, harsh preparation conditions of hollow structure silver powder, and difficulty of hollow structure silver powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

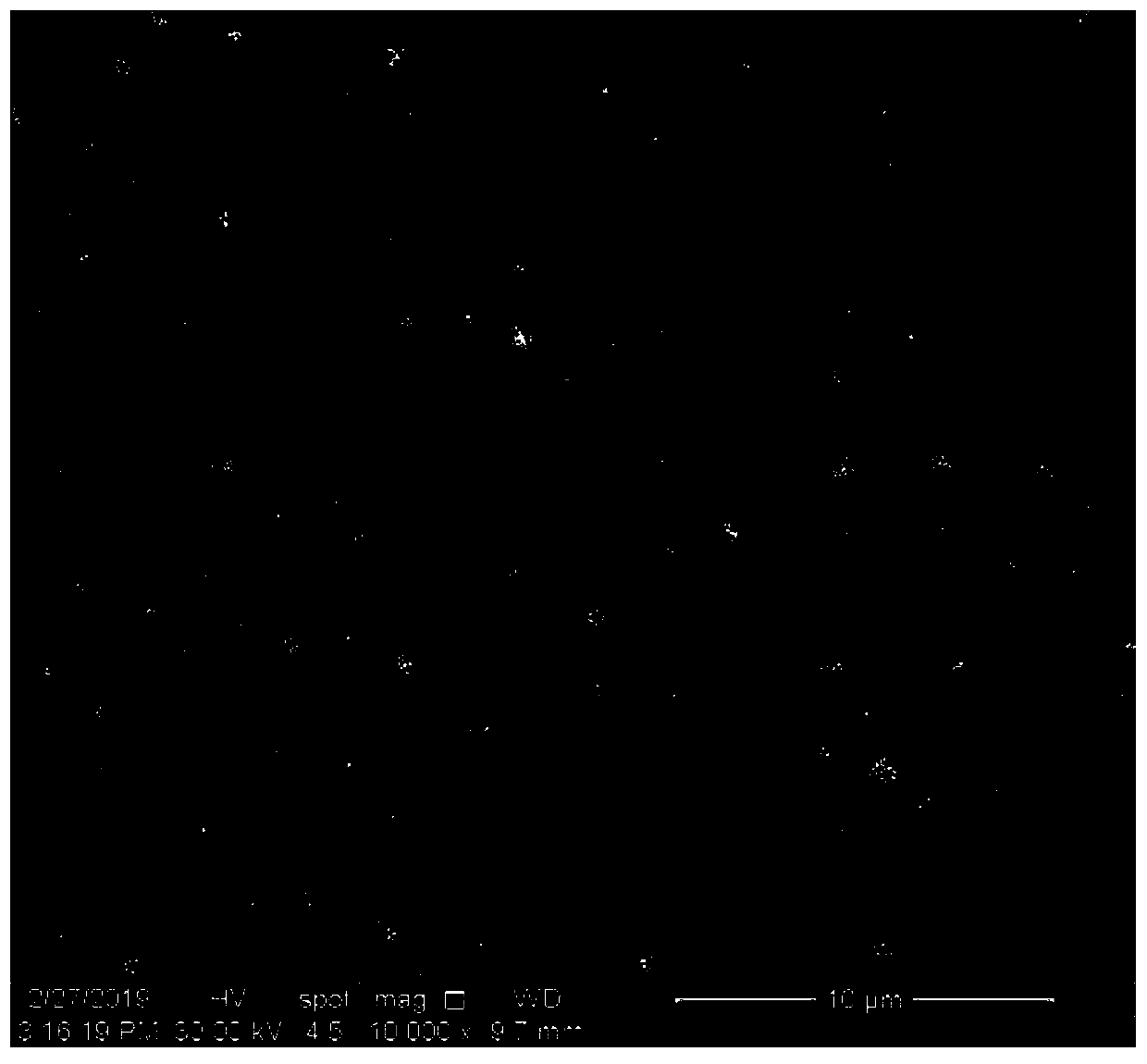

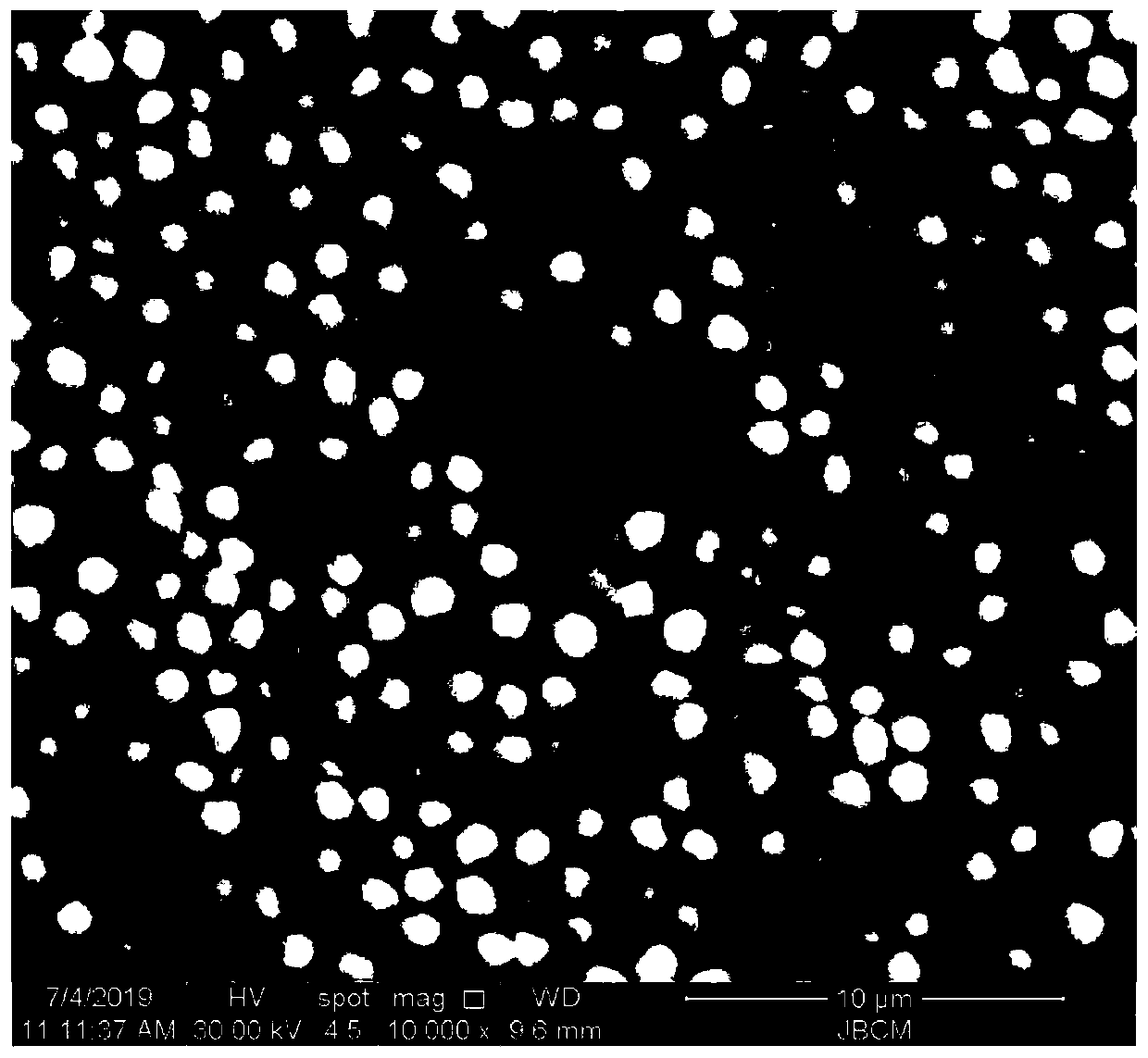

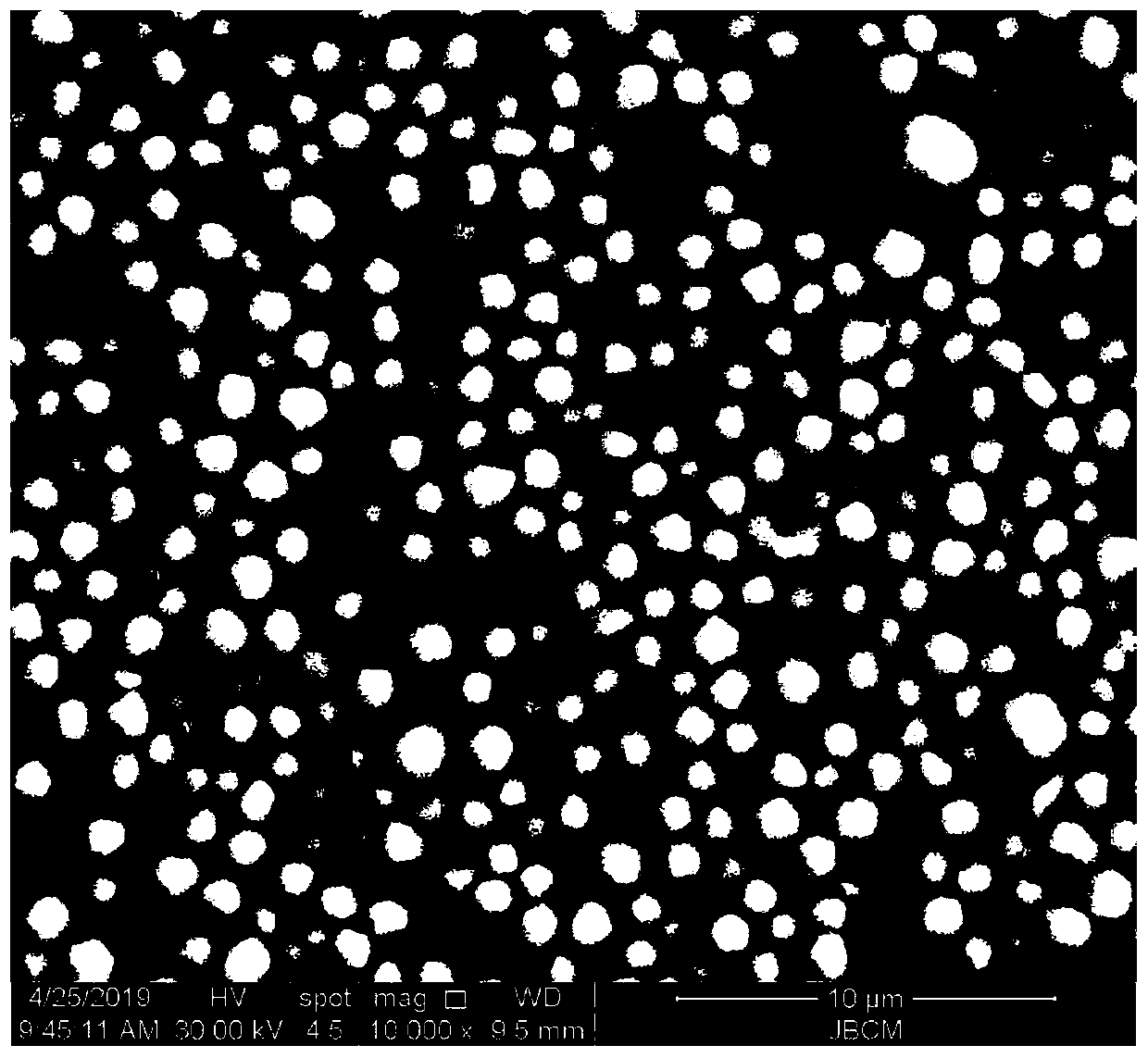

Image

Examples

Embodiment 1

[0032] A preparation method of microcrystalline silver powder containing a hollow structure, comprising the following steps:

[0033] (1) Silver nitrate solution, ascorbic acid solution and dispersant solution containing concentrated nitric acid are configured according to concentration;

[0034] (2) Control the flow rate of the dropping rate of 100-400mL / min, add the silver nitrate solution and the ascorbic acid solution into the dispersant solution at the same time, stop adding the silver salt solution when the remaining 10% of the silver nitrate solution is left, and wait for the ascorbic acid solution to be added to the reaction kettle After neutralization, add hydrazine hydrate and emulsifier into the reaction kettle, and drop the remaining silver nitrate solution at the same time;

[0035] (3) After the reaction is finished, separate the supernatant to obtain silver powder, wash the silver powder with deionized water and ethanol, and dry to obtain microcrystalline silver...

Embodiment 2

[0038] A preparation method of microcrystalline silver powder containing a hollow structure, comprising the following steps:

[0039] (1) Silver nitrate solution, ascorbic acid solution and dispersant solution containing concentrated nitric acid are configured according to concentration;

[0040] (2) Control the flow rate of the dropping rate of 100-400mL / min, add the silver nitrate solution and the ascorbic acid solution to the dispersant solution at the same time, stop adding the silver salt solution when the remaining 3% of the silver nitrate solution is left, and wait for the ascorbic acid solution to be added to the reaction kettle After neutralization, add hydrazine hydrate and emulsifier into the reaction kettle, and drop the remaining silver nitrate solution at the same time;

[0041] (3) After the reaction is finished, separate the supernatant to obtain silver powder, wash the silver powder with deionized water and ethanol, and dry to obtain microcrystalline silver po...

Embodiment 3

[0044] A preparation method of microcrystalline silver powder containing a hollow structure, comprising the following steps:

[0045] (1) Silver nitrate solution, ascorbic acid solution and dispersant solution containing concentrated nitric acid are configured according to concentration;

[0046] (2) Control the flow rate of the dropping rate of 100-400mL / min, add the silver nitrate solution and the ascorbic acid solution to the dispersant solution at the same time, stop adding the silver salt solution when the remaining 15% of the silver nitrate solution is left, and wait for the ascorbic acid solution to be added to the reaction kettle After neutralization, add hydrazine hydrate and emulsifier into the reaction kettle, and drop the remaining silver nitrate solution at the same time;

[0047] (3) After the reaction is finished, separate the supernatant to obtain silver powder, wash the silver powder with deionized water and ethanol, and dry to obtain microcrystalline silver p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com