Incinerator slag treatment system and treatment method

A technology of incineration slag and treatment system, which is applied in the direction of filtration treatment, multi-stage water treatment, chemical instruments and methods, etc., which can solve the problems of high construction cost of incineration slag treatment system, low utilization rate of incineration slag raw materials, and poor water treatment effect and other problems, to achieve the effect of strengthening the clarification and settlement effect, low processing cost and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

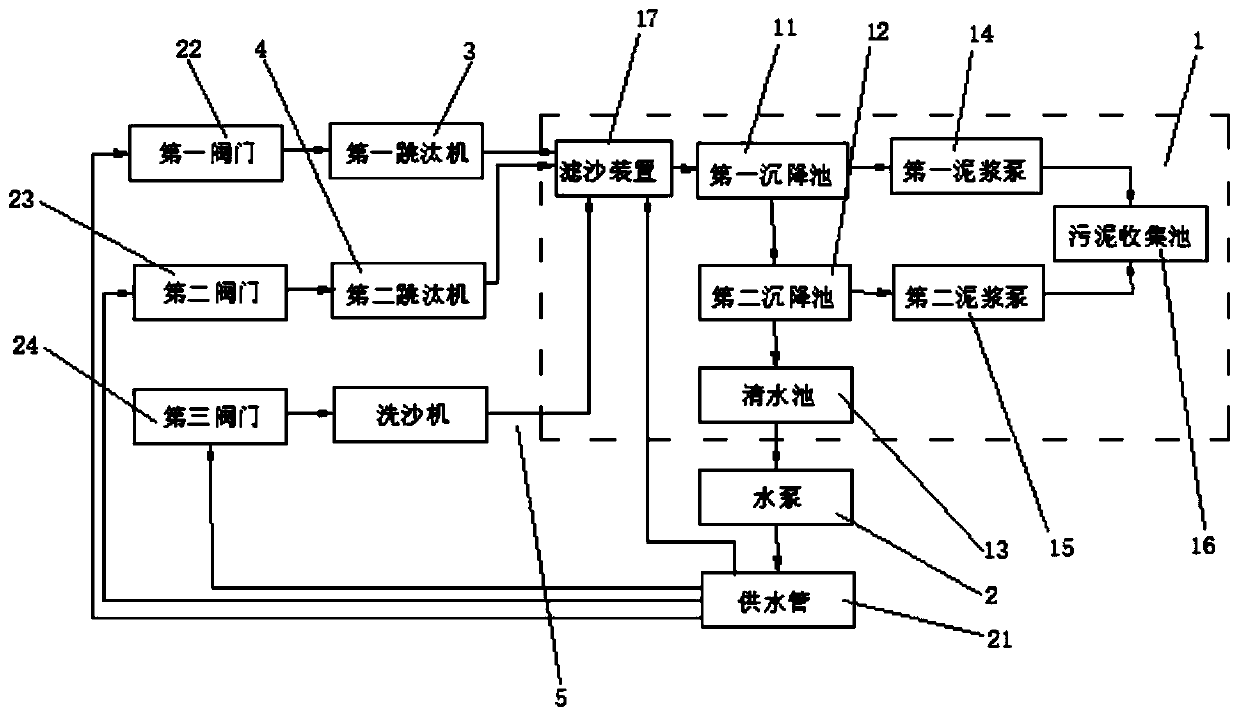

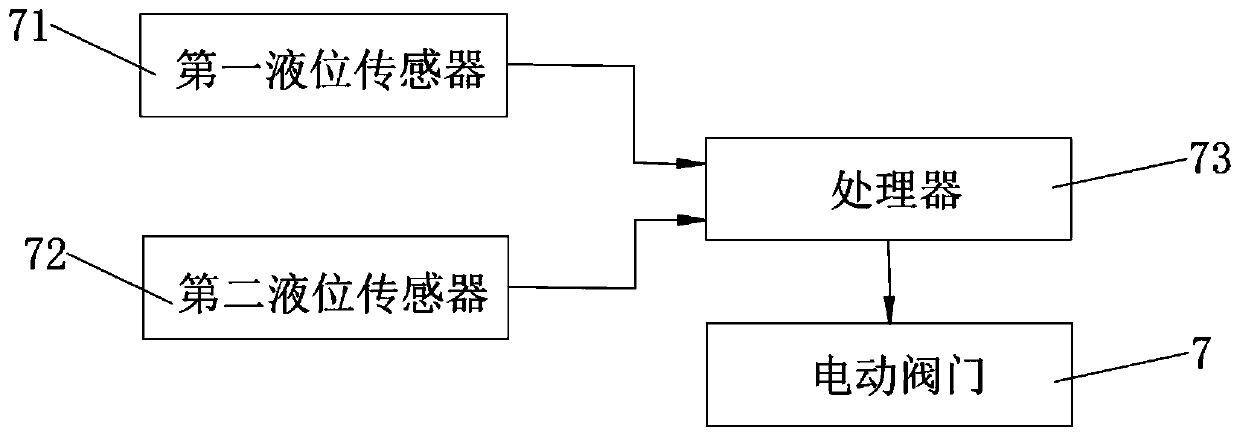

[0038] like figure 1 and figure 2 As shown, an incinerator slag treatment system includes a sewage circulation treatment unit 1, a water pump 2, a water supply pipe 21, a first valve 22, a second valve 23, a third valve 24, and successively connected vibrating screen devices 25, pig cage sieves Device 26, crushing device 27 and magnetic separator 28, described incineration slag processing system also comprises the first jig 3 that is connected with the first discharging end of magnetic separator 28, the second discharging end with magnetic separator 28 The second jig 4 connected to the end, the sand washing machine 5 connected to the first discharge end of the first jig 3 and the aluminum jigger 6 connected to the second discharge end of the first jig 3, The water outlet of the first jig 3, the water outlet of the second jig 4 and the water outlet of the sand washing machine 5 are all connected to the water inlet of the sewage circulation treatment unit 1, and the water inle...

Embodiment 2

[0060] In this embodiment, an incineration slag treatment method, the treatment method adopts the above-mentioned incineration slag treatment system, and the treatment method includes the following steps:

[0061] Step A, the incineration slag enters the vibrating screen device 25 for the first screening;

[0062] Step B, the larger incineration slag of particle size continues to enter the pig cage sieve device 26, and the pig cage sieve device 26 disperses the agglomerated incinerator slag and carries out second sub-sieving to the incinerator slag;

[0063] Step C, using the crushing device 27 to crush the larger incineration slag screened out by the pig cage sieve device 26, and the crushed incineration slag enters the magnetic separator 28;

[0064] Step D, using the magnetic separator 28 to sort magnetic materials and non-magnetic materials, the non-magnetic materials enter the first jig 3 from the first discharge end of the magnetic separator 28 and pass through the first...

Embodiment 3

[0076] In this embodiment, in the sewage treatment step (b), the first treatment agent includes the following raw materials in parts by weight: 10-15 parts of anionic polyacrylamide, 15-20 parts of slaked lime, and 6-10 parts of slag powder.

[0077] Further, the alumina content in the slag powder is 17%, and the calcium oxide content is 1.5%.

[0078] Further, in the step (c), the second treatment agent includes the following raw materials in parts by weight: 20 parts of anionic polyacrylamide, 12 parts of polyaluminum chloride, 8 parts of maleic acid-acrylic acid copolymer, carboxymethyl sulfide 4 parts of urea chitosan, 7 parts of active foaming agent, 10 parts of lignin, 7 parts of citric acid, 8 parts of dimethyl diallyl ammonium chloride, monocetyl maleate sodium salt 5 servings.

[0079] Further, the active foaming agent is composed of fatty alcohol polyoxyethylene ether and sodium α-alkenyl sulfonate in a mass ratio of 1:2.

[0080] The rest of the content of this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com