In-situ preparation method and application of polymer electrolyte

An in-situ preparation and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolytes, solid electrolytes, etc., can solve problems such as reducing the decomposition of liquid electrolytes, shorten the preparation period, solve leakage, and inhibit growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The in-situ preparation method of a polymer electrolyte provided in this example is as follows:

[0030] S1: Under the condition of anhydrous and oxygen isolation, the monomer methyl methacrylate and polyethylene glycol methyl ether methacrylate with a relative molecular mass of 300, the initiator 2-bromophenyl acetate and lithium Salt lithium perchlorate reaction raw materials are mixed, stir to form precursor solution A1; Methyl methacrylate, polyethylene glycol methyl ether methacrylate, 2-bromophenyl acetate, lithium perchlorate molar ratio is 20:10:1:6.

[0031] The specific configuration process is: S1: Weigh 0.1425g lithium perchlorate in the glove box and put it into the eggplant-shaped bottle, take 0.5ml methyl methacrylate and 1ml polyethylene glycol methyl ether methacrylate and add it to the eggplant-shaped bottle In the bottle, after 20 minutes of magnetic stirring, 3 microliters of ethyl 2-bromophenylacetate was added, and the stirring was continued for 2...

Embodiment 2

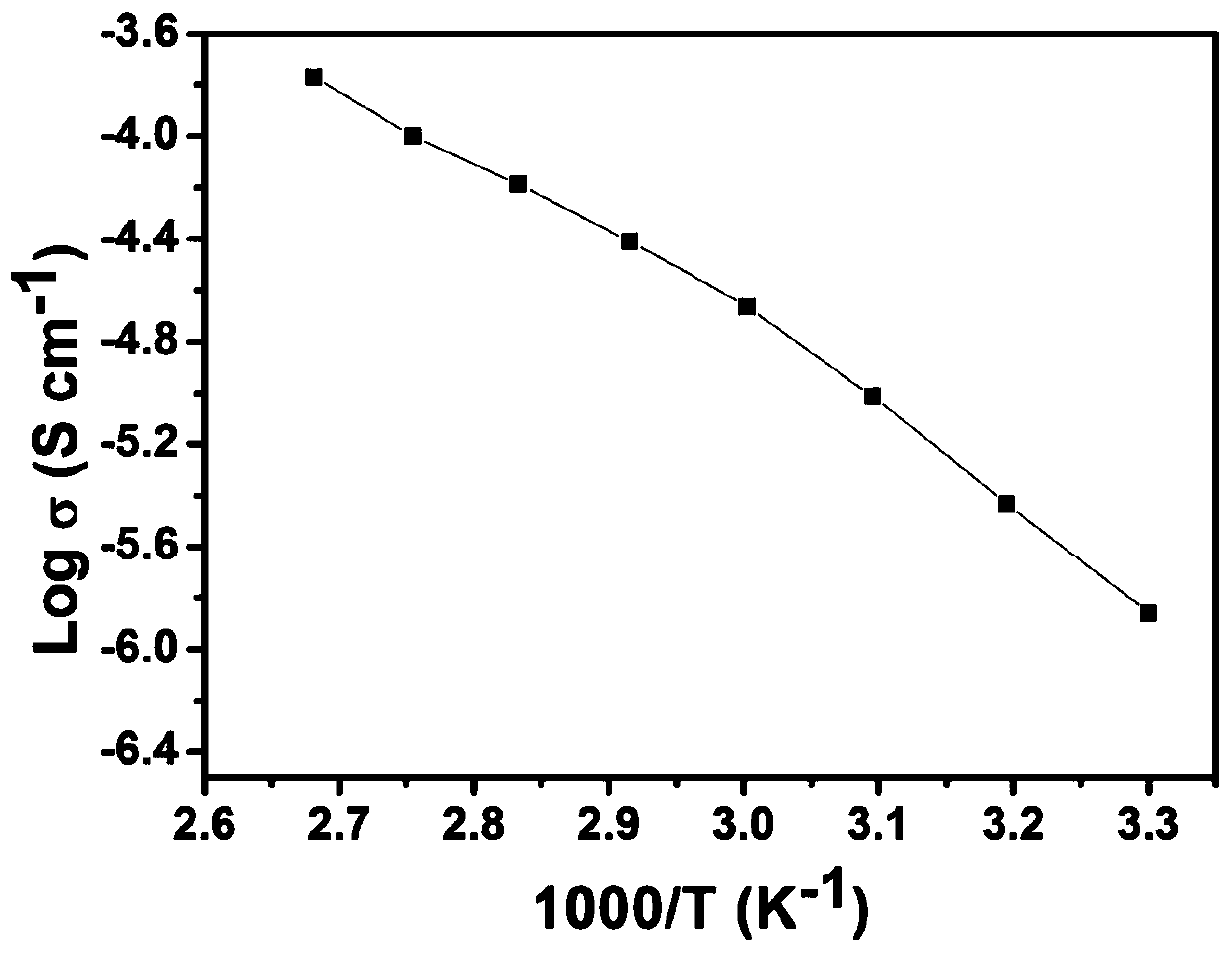

[0035] The difference between embodiment 2 and embodiment 1 is that the monomer is butyl methacrylate and polyethylene glycol methyl ether methacrylate with a relative molecular mass of 500, and the initiator is 2-iodo-2-methyl Propionitrile, the lithium salt is lithium hexafluorophosphate, stir well to form the precursor solution B1, the molar ratio of butyl methacrylate, polyethylene glycol methyl ether methacrylate, 2-iodo-2 methylpropionitrile, and lithium hexafluorophosphate is 20:30: 1:8; the rest of the steps are the same as in Example 1; the polymer B2 and the polymer electrolyte B3 with a number-average molecular mass of 45300 are obtained, and the lithium ion conductivity of the polymer electrolyte B3 measured at room temperature is 7.8×10 -5 s / cm.

Embodiment 3

[0037] The difference between Example 3 and Example 1 is that the monomers are methyl acrylate, styrene and polyethylene glycol methyl ether methacrylate with a relative molecular mass of 475, and the initiator is 2-iodo-2-methacrylate propionitrile, the lithium salt is lithium dioxalate borate, stir well to form a precursor solution C1, methyl acrylate, styrene, polyethylene glycol methyl ether methacrylate, 2-iodo-2-methylpropionitrile, dioxalic acid The molar ratio of lithium borate is 20:10:20:1:9; the remaining steps are the same as in Example 1; the polymer C2 and the polymer electrolyte C3 with a number average relative molecular weight of 47300 are obtained, and the polymer electrolyte C3 is at room temperature The lithium ion conductivity was measured to be 6.5×10 -5 s / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com