Device and method for preparing or treating auxiliary film aided by pulse electric field

A technology of film treatment and treatment method, applied in the field of exploring film materials, can solve the problems of slow cooling, slow heating and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of TiAlN coating under pulsed electric field

[0058] Step 1, cleaning of the substrate

[0059] After grinding and polishing the cemented carbide sheet, use acetone and alcohol to ultrasonically clean the sapphire substrate for 15 minutes. After cleaning, use high-purity inert gas to dry it. Use a pulse electric field clamp to fix the substrate and put it into a vacuum chamber.

[0060] Step 2, preparation of TiAlN coating under pulsed electric field

[0061] Using the same preparation conditions as in Comparative Example 1, a pulse current was connected during the preparation process to prepare a TiAlN coating under a pulse electric field. Among them, the pulse current intensity is 15A, the pulse width is 10s, and the processing time is 5-10min.

[0062] Step 3, turn off the magnetron sputtering equipment, take out the sample after degassing, put it into a centrifuge tube, and inject inert high-purity Ar for subsequent detection.

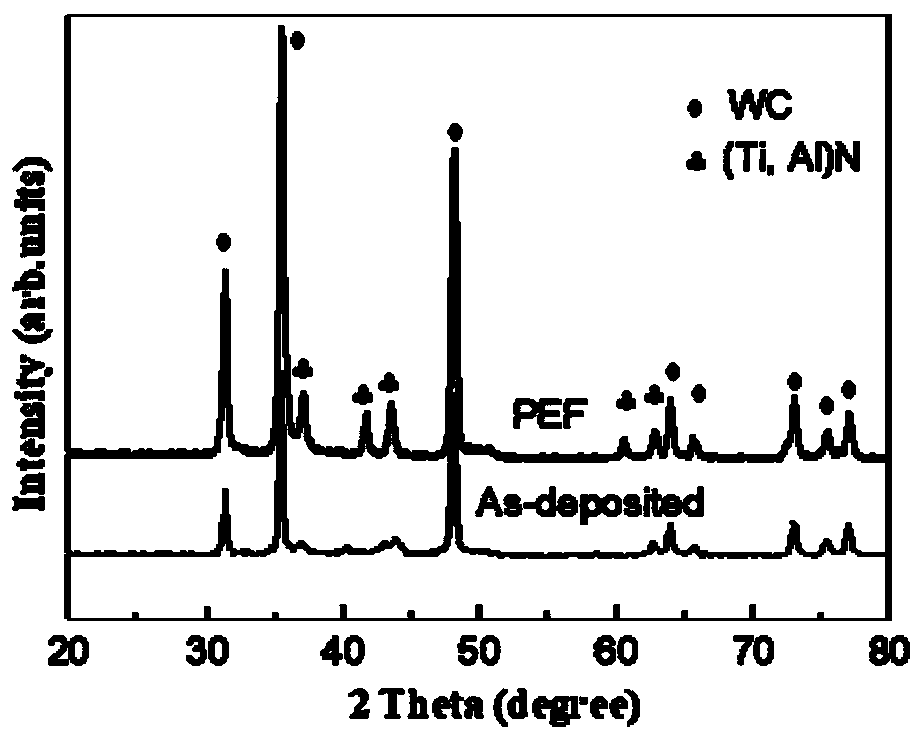

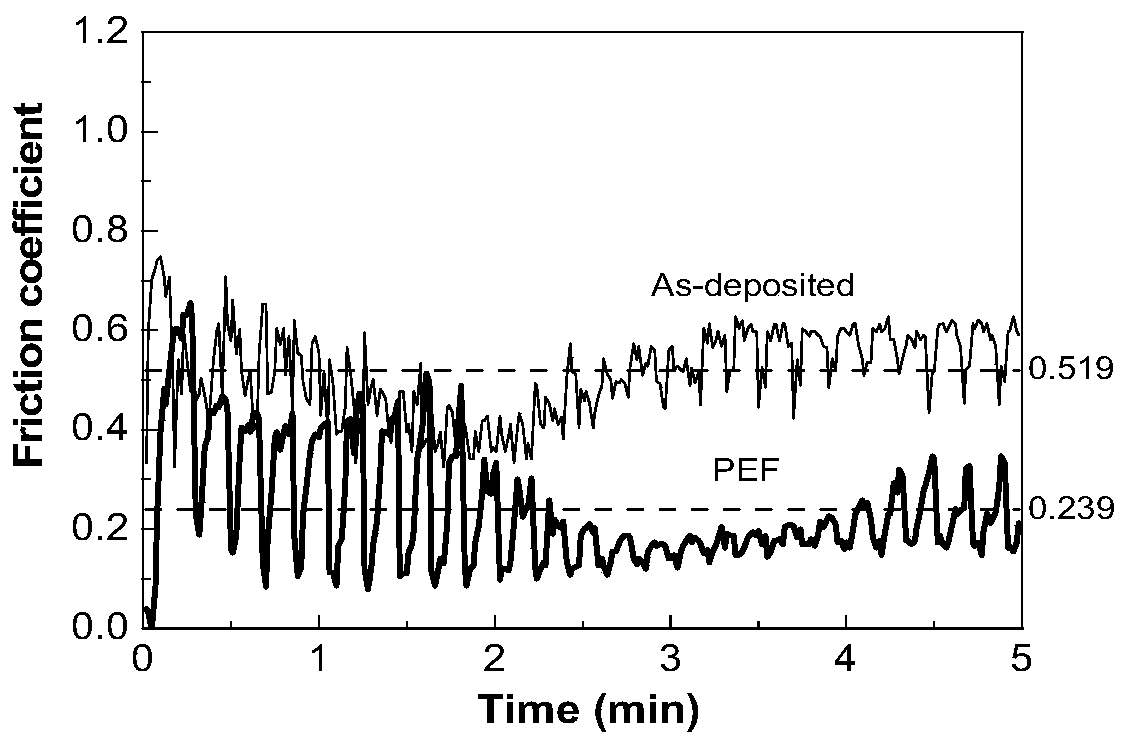

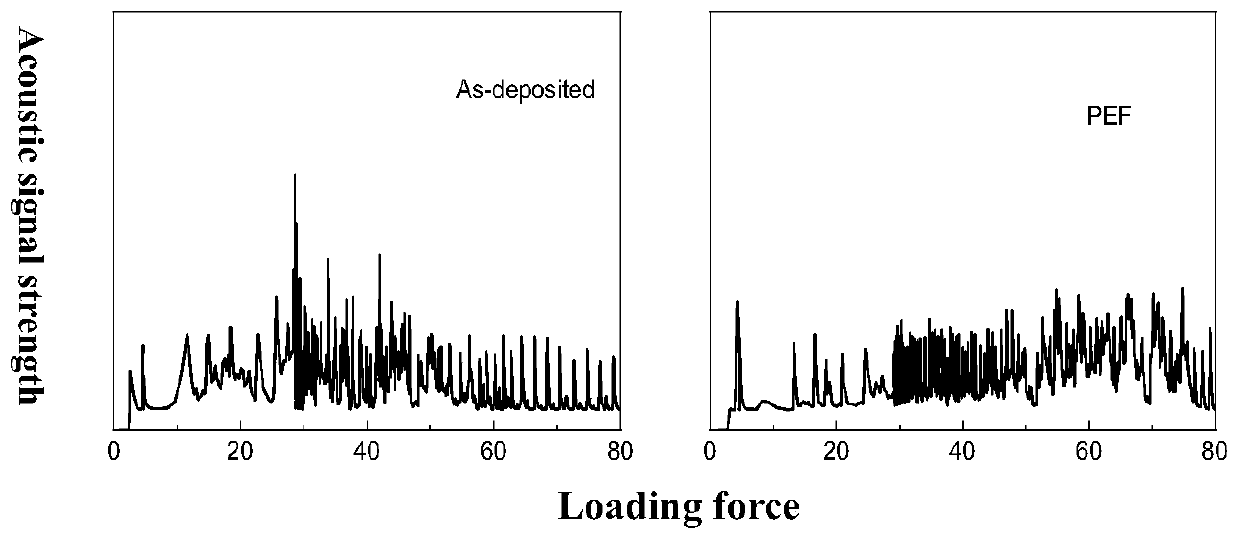

[0063] figure 1 XRD ...

Embodiment 2

[0078] Oxidation Treatment of Ca-Co Thin Films Using Pulse Electric Field

[0079] Step 1, connect the circuit

[0080] Use a clamp to fix the film, and connect the clamp and the pulse current generator to form a closed loop.

[0081] Step 2, pulsed electric field oxidation treatment of Ca-Co film

[0082] After setting the pulse electric field pulse current 0.01A, pulse width 1s, pulse rise time 0.05A / s and other parameters, start processing, processing time 1h.

[0083] Step 3, end of processing, take out the sample

[0084] After the timing is over, the sample is taken out, put into a centrifuge tube, and passed through inert high-purity Ar for subsequent detection.

[0085] Figure 6 It is a comparison chart of the XRD diffraction pattern of Co-Ca in Example 2 when it is oxidized by a pulsed electric field and Comparative Example 3 when it is oxidized by a tube furnace.

[0086] From the XRD diffraction pattern, it can be found that the Co-Ca compound can be oxidized ...

Embodiment 3

[0096] Pulsed electric field heat treatment of Bi 2 Te 3 film

[0097] Step 1, connect the circuit

[0098] Use a clamp to fix the film, and connect the clamp and the pulse current generator to form a closed loop. Fix the thermocouple above the film and connect the temperature collector to the display.

[0099] Step 2, pulsed electric field heat treatment of Bi 2 Te 3 film

[0100] After setting the pulse electric field pulse current 0.05A, pulse width 1s, pulse rise time 0.05A / s and other parameters, start processing, processing time 1h, and collect temperature changes at the same time.

[0101] Step 3, end of processing, take out the sample

[0102] After the timing is over, the sample is taken out, put into a centrifuge tube, and passed through inert high-purity Ar for subsequent detection.

[0103] Figure 8 Deposited Bi prepared for Comparative Example 4 2 Te 3 Film and the Bi after pulse electric field heat treatment of embodiment 3 2 Te 3 SEM comparison ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com