Process system for preparing deuterium-depleted water and method for preparing deuterium-depleted water applied process system

A process system and technology of deuterium-depleted water, applied in chemical instruments and methods, water, electrodes, etc., can solve the problems of small hydrogen isotope separation coefficient and difficulty in separating deuterium, and achieve good corrosion resistance, improve separation coefficient, and high hydrogen evolution. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Experimental principle and setting method

[0022] The basic principle of electrolysis of water is to split water by passing direct current in the presence of electrolyte. The general form of electrolyzed water can be described by formula (1):

[0023]

[0024] When deuterium exists in water, due to the difference in mobility between protium ions and deuterium ions in solution, plus the overpotential of deuterium is greater than that of protium, protium is preferentially discharged on the electrode. Therefore, when water is electrolyzed, the deuterium in the released hydrogen is depleted, while the deuterium in the solution is enriched. The separation coefficient of protium and deuterium varies greatly due to the difference in cathode material, electrolyte properties, and electrolysis conditions.

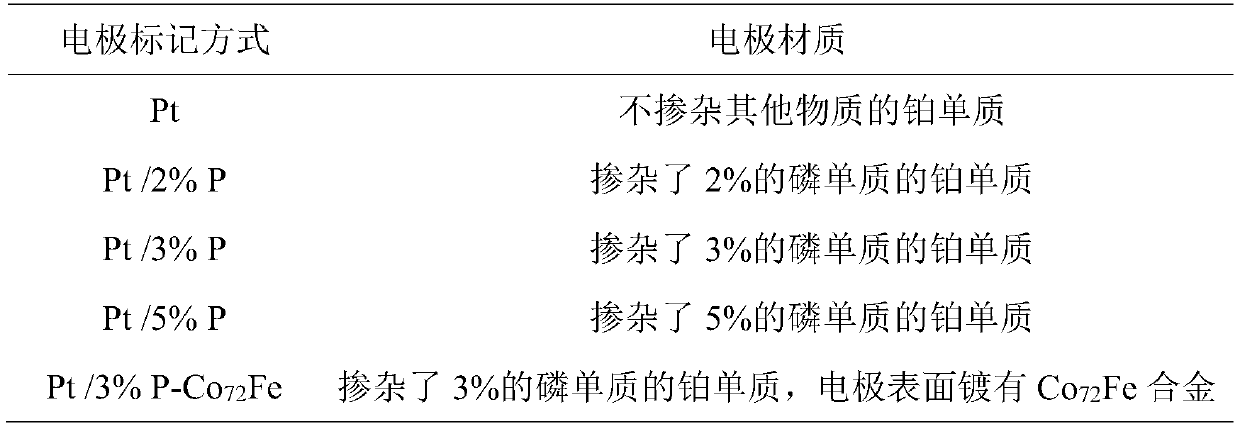

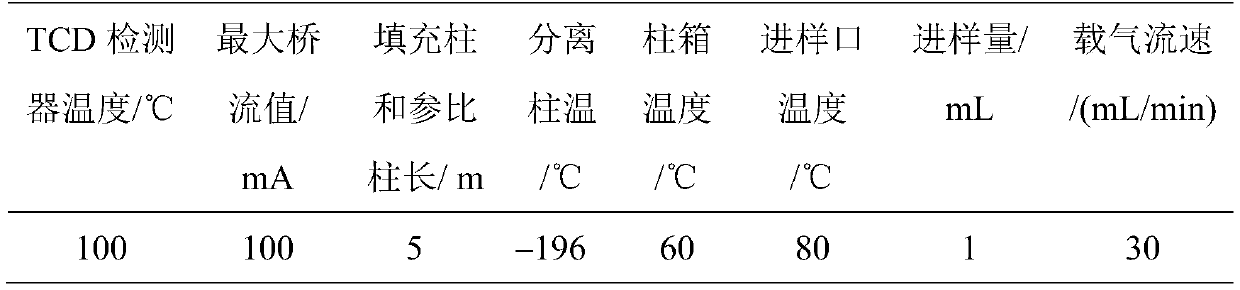

[0025]In this embodiment, different cathode materials are used to electrolyze raw water, and the influence of the cathode electrode material on the separation coeffic...

Embodiment 2

[0045] The process system for preparing deuterium-depleted water used in this example includes a raw material water permeator, a hydrogen generator, a hydrogen collector, a gaseous deuterium separator, a hydrogen burner and a water vapor condensing unit connected in sequence through pipelines. The wall of the raw water permeator is provided with an exhaust port communicating with the outside world, and the inside is filled with ZrO 2 (5%V 2 o 3 )filler. An electrolytic cell, a DC power supply and electrodes are provided in the hydrogen generator. The electrolytic cell is provided with a cathode chamber and an anode chamber which are mutually isolated. The cathode and the anode are respectively inserted into the cathode chamber and the anode chamber. , the electrolyte solution that adopts is the KOH solution of 0.5M, with Pt electrode as anode, with the Pt / 3%P-Co in embodiment 1 72 Fe is used as a cathode, and a copper wire is used to connect the electrode and a DC power sup...

Embodiment 3

[0057] Instruments and Equipment: Isotope Ratio Mass Spectrometer 253Plus 10kV (Thermo Fisher Scientific).

[0058] Test water sample: embodiment 2, comparative example 1, comparative example 2, comparative example 3, the raw material water that comparative example 4 adopts; The deuterium-depleted water product of embodiment 2; The deuterium-depleted water of comparative example 1 Product; the deuterium-depleted water product of comparative example 2; the deuterium-depleted water product of comparative example 3; the deuterium-depleted water product of comparative example 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com