Method for calculating groove width of narrow gap laser filler wire welded plat

A technology of laser wire filling and groove width, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large differences in the concentration of welding wire alloy elements, complex influence laws, large welding heat input, etc., to reduce the number of tests. Quantity and cycle time, reduce the trial and error process, reduce the effect of application cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

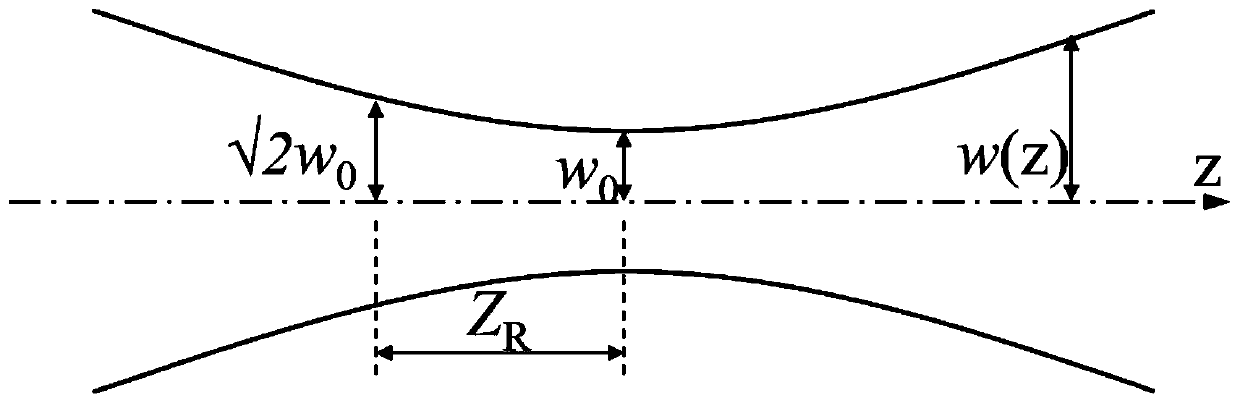

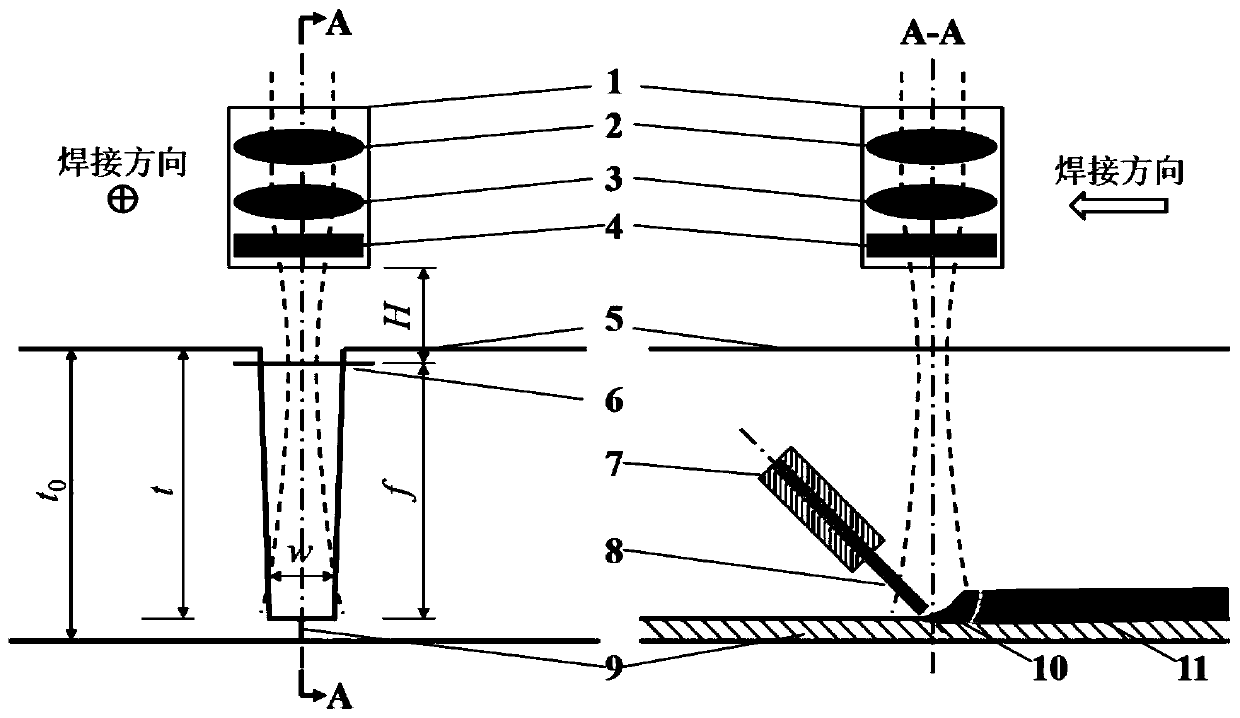

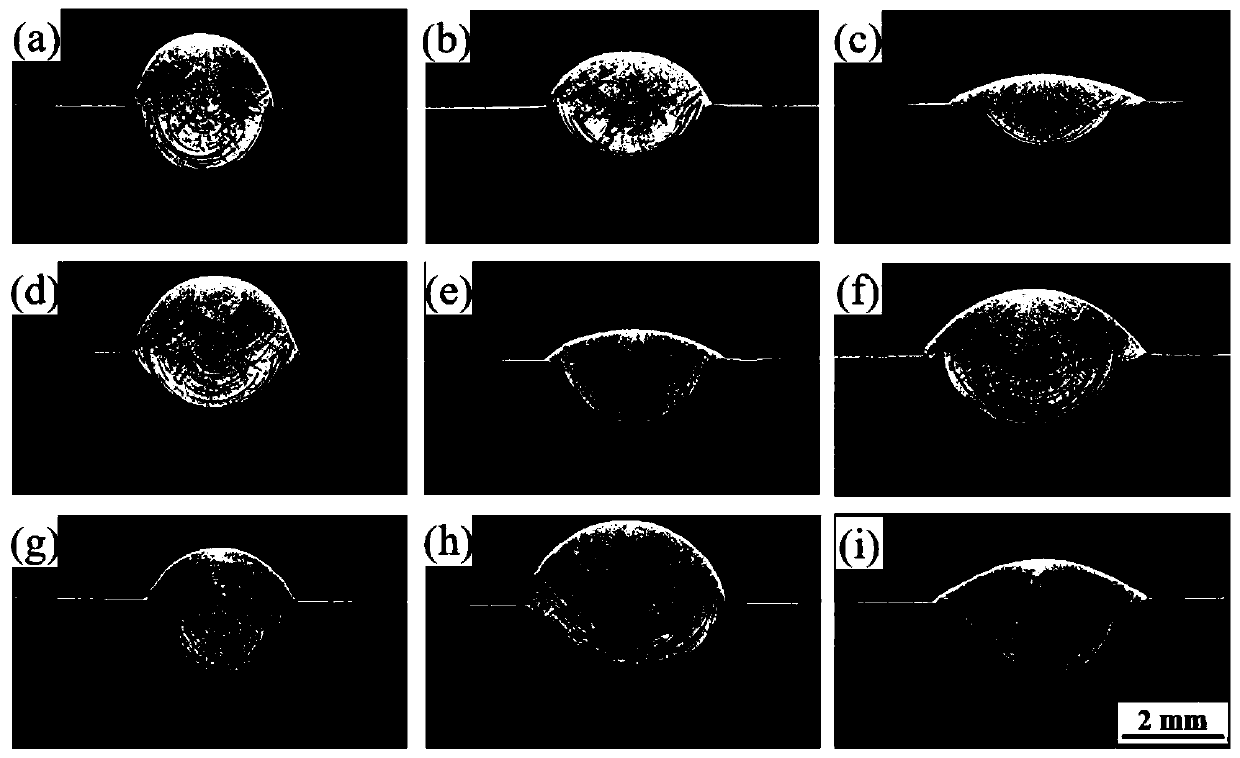

[0072] Take the butt welding of two 300mm (length)*120mm (width)*6.6mm (thickness) D406A ultra-high-strength steel plates as an example, the length of the weld bead is 300mm. Using IPG's Nd:YAG 4kW multi-mode infrared fiber laser as a heat source, the laser beam is basically incident perpendicular to the surface of the test plate. In order to protect the laser lens group, the laser head is deflected backward by 5°. The incident fiber diameter of the laser welding head is φ200μm, and the focal length of the collimating lens is F c 150mm, focusing lens distance F 150mm, beam parameter product BPP 7.0mm*mrad, laser beam wavelength λ1070nm. The welding wire with a diameter of 1.2 mm is front-mounted, and the wire feeding mechanism sends the welding wire into the molten pool, and the angle between the wire feeding gun and the horizontal is 45°; according to formula (5), it can be obtained In order to achieve narrow-gap laser wire-filled butt welding of 6.6mm thick plates, the ga...

Embodiment 2

[0079] Taking the butt welding of two 90mm (length)*45mm (width)*20mm (thickness) D406A ultra-high-strength steel plates as an example, the length of the weld bead is 90mm. Using IPG's Nd:YAG 4kW multi-mode infrared fiber laser as a heat source, the laser beam is basically incident perpendicular to the surface of the test plate. In order to protect the laser lens group, the laser head is deflected backward by 5°. The incident fiber diameter of the laser welding head is φ200μm, and the focal length of the collimating lens is F c 150mm, focusing lens distance F 150mm, beam parameter product BPP 7.0mm*mrad, laser beam wavelength λ1070nm. The welding wire with a diameter of 1.2mm is front-mounted, and the welding wire is sent into the molten pool by the wire feeding mechanism, and the angle between the wire feeding gun and the horizontal is 45°. According to formula (5), we can get In order to achieve narrow gap laser wire-filled butt welding of 20mm thick plates, the gap widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com