Adjustable sample plate for backing plate marking-out

An adjustable and prototype technology, applied to workshop equipment, manufacturing tools, etc., can solve the problems of increased cost, difficulty, and low probability of duplication of backing plates in manufacturing samples, and achieve the goal of reducing storage pressure, reducing waste, and shortening the production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

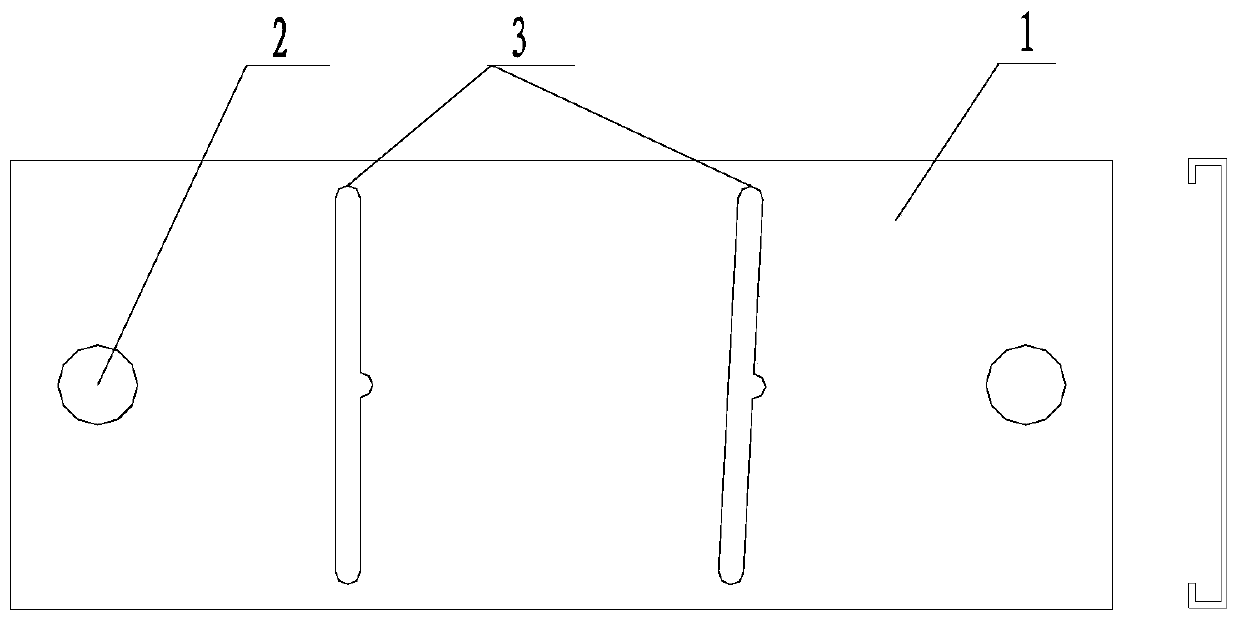

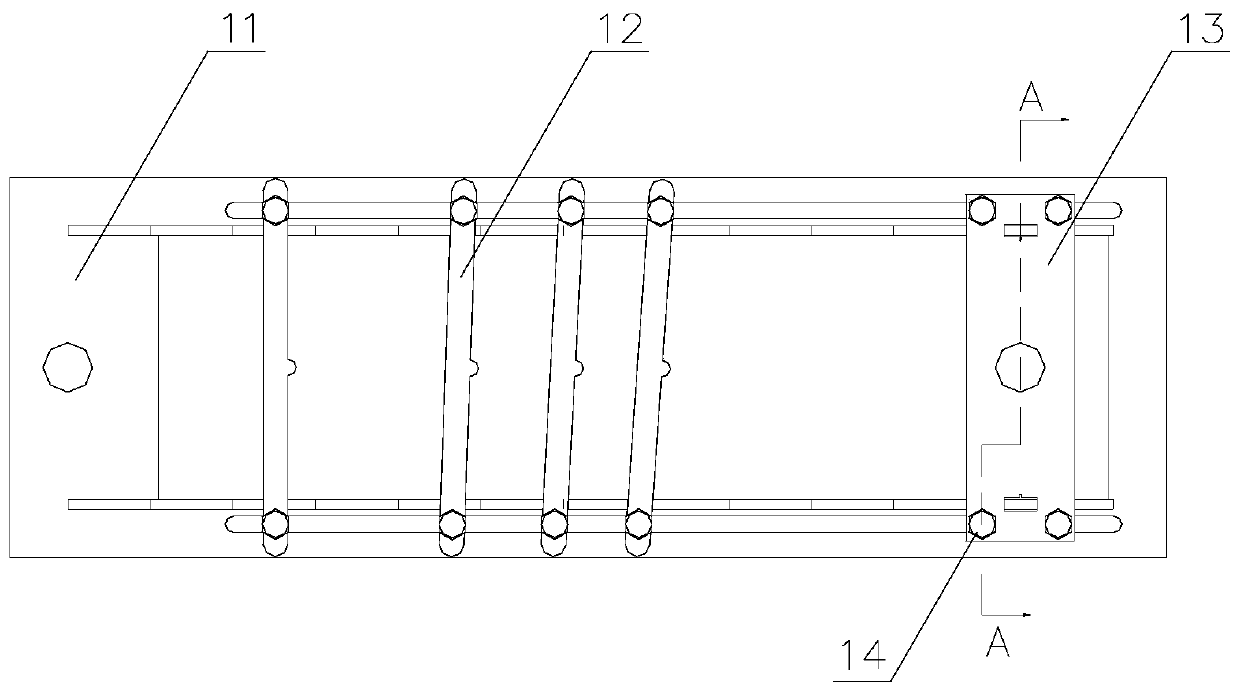

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] In the present invention, the adjustable template used for scribing a backing board, the template main body 11 is a box-shaped structure with a hollow center, and has a reinforced structure formed by bending down the extension parts of two sides. A slideway 18 is provided on each side frame of the hollow part of the template body 11, and the two slideways 18 are parallel to each other. A positioning plate 13 and multiple supporting feet 12 are installed between the two slideways 18. The ends of the supporting feet 12 and the slideways 18, and the positioning plate 13 and the slideways 18 are adjustable and fixed. Installation; A position hole 16 is set at one end of the template body 11, and the positioning plate 13 is installed at the other end of the template body 11 and has a positioning hole. The connecting line between the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com