Corrosion detection electrode in conductive concrete environment and preparation and detection method

A conductive concrete and corrosion detection technology, which is applied in the direction of manufacturing tools, measuring devices, metal processing equipment, etc., can solve the problems of electrolyte infiltration into gaps, affecting test results, and difficult removal of electrodes, and achieves good isolation effect and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

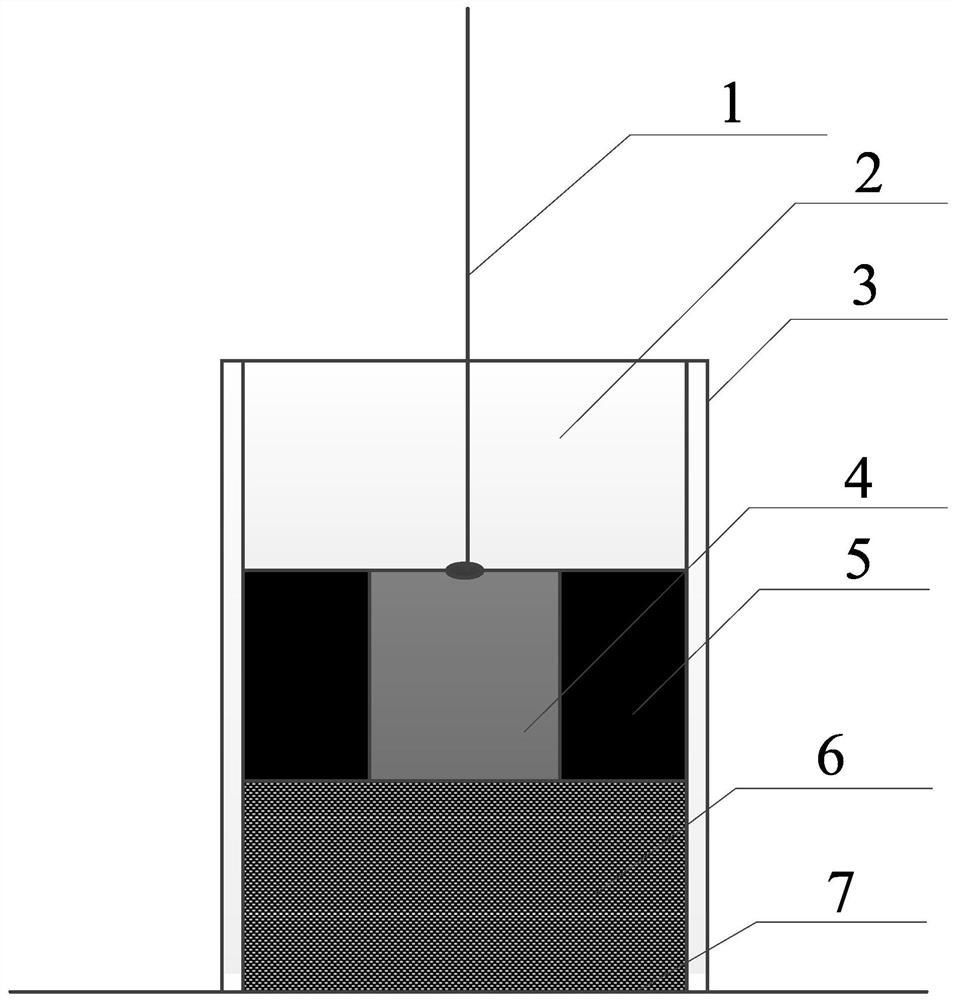

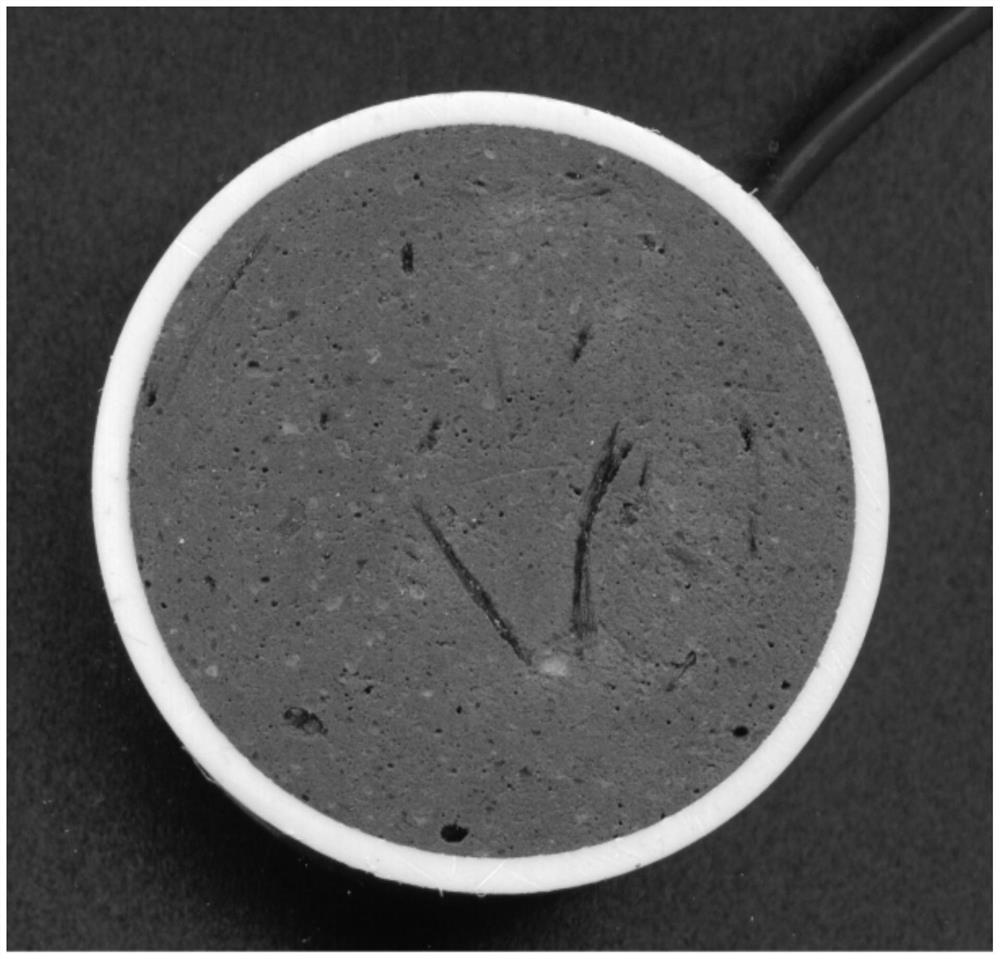

[0036] This embodiment combines Figure 1-3, first process a cylindrical carbon steel metal sample 4 with a diameter of Φ12 mm and a length of 10 mm by wire cutting, place the carbon steel metal sample 4 in a hot mounting machine, add bakelite powder that has submerged the sample for about 15 mm, Set the heating temperature to 135° C. and the holding time for 15 minutes to obtain a sample wrapped with the thermal mosaic layer 5 . Then use 80-mesh coarse sandpaper to grind the upper and lower end surfaces of the sample wrapped with the thermal mosaic layer 5, exposing the working surface and welding surface of the metal to be tested respectively. The copper wire 1 with a rubber protective sheath is welded on the welding surface by spot welding, and the working surface is further polished step by step with metallographic sandpaper of 400 mesh to 2000 mesh to obtain a smooth and bright working surface. Take another PVC electrode mold tube 3 with a diameter slightly larger than t...

Embodiment 2

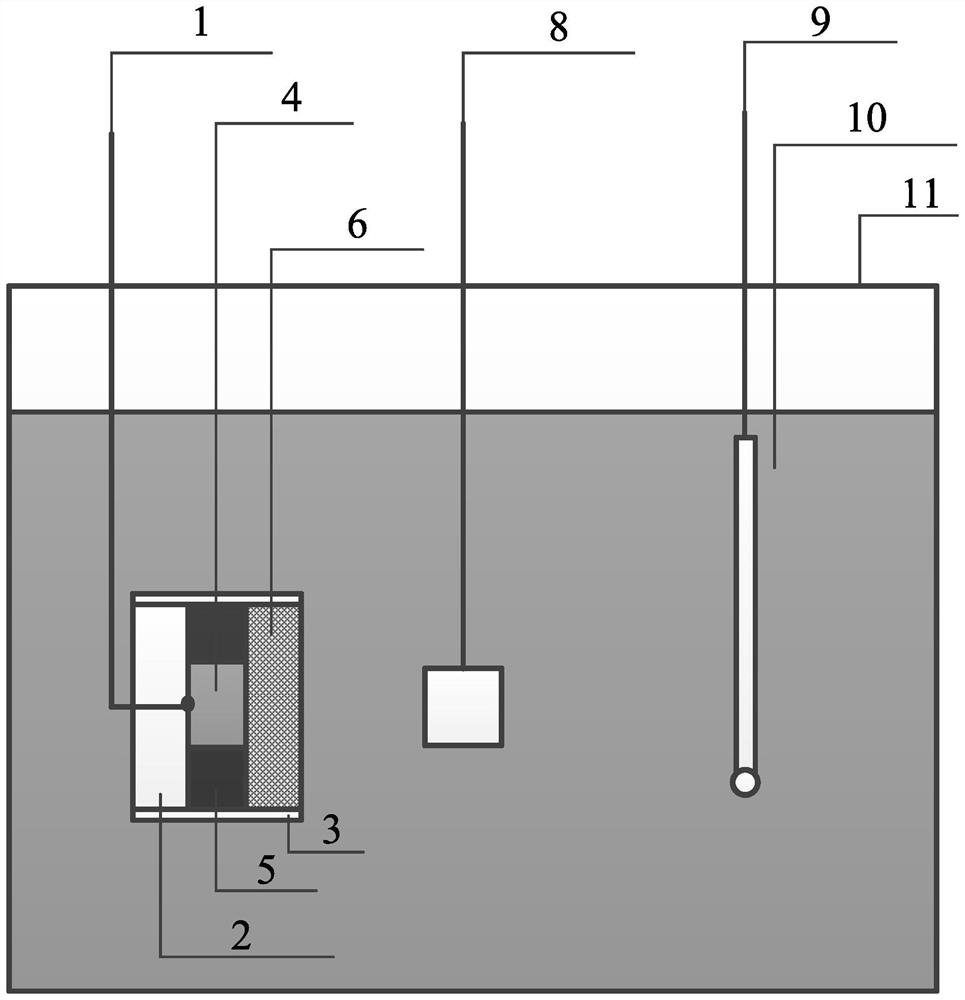

[0038] In this embodiment, the electrochemical test is carried out on the electrode prepared in Example 1. The prepared working electrode is vertically fixed inside the glass container 11, and the auxiliary electrode 8 and the reference electrode 9 are inserted in parallel with the working electrode. The auxiliary electrode 8 is a platinum electrode. , the reference electrode 9 is a calomel electrode, and then 3.5wt% NaCl solution is added as the electrolyte 10 for the electrochemical test, and the electrochemical workstation is connected to the three-electrode system for constant potential polarization, electrochemical impedance spectroscopy and other tests. This example can not only be used to study Cl — Corrosion mechanism of carbon steel in conductive concrete under infiltration. It is also possible to prepare multiple working electrodes by pouring different types of conductive concrete for research, and to evaluate the corrosion resistance of carbon steel in different typ...

Embodiment 3

[0040] This embodiment combines Figure 1-3 , first process a cylindrical carbon steel metal sample 4 with a diameter of Φ15 mm and a length of 15 mm by wire cutting, place the carbon steel metal sample 4 in a hot mounting machine, add bakelite powder that has submerged the sample for about 15 mm, Set the heating temperature to 145° C. and the holding time for 15 minutes to obtain a sample wrapped with the thermal mosaic layer 5 . Then use 80-mesh coarse sandpaper to grind the upper and lower end surfaces of the sample wrapped with the thermal mosaic layer 5, exposing the working surface and welding surface of the metal to be tested respectively. The copper wire 1 with a rubber protective sheath is welded on the welding surface by spot welding, and the working surface is further polished step by step with metallographic sandpaper of 400 mesh to 2000 mesh to obtain a smooth and bright working surface. Take another PVC electrode mold tube 3 with a diameter slightly larger than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com