Zero discharge power system for performing cascade composite recycling recovery on CO2 by utilizing LNG cold energy

A compound cycle and power system technology, applied in fuel systems, machines/engines, cold treatment separation, etc., can solve the problems of inability to guarantee the decomposition of all gas hydrates, corrosion of high-temperature gas hydrates, and unsustainable use of equipment, shortening equipment Service life, the effect of reducing power supply pressure and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objectives, characteristics and advantages of the present invention more obvious and understandable, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

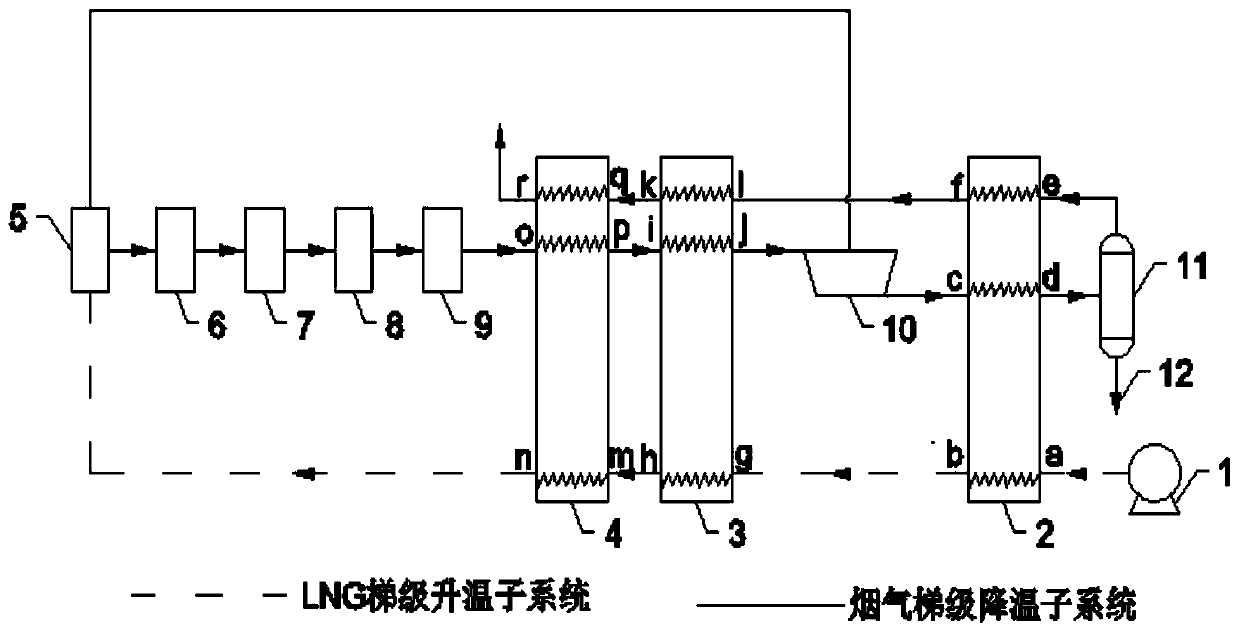

[0029] Such as figure 1 Shown is a cascade combined cycle recovery of CO using LNG cold energy according to an embodiment of the present invention 2 The zero-emission power system includes an LNG cascade heating subsystem and a flue gas cascade cooling subsystem. The LNG cascade heating subsystem includes: LNG pump 1, gas-liquid heat exchanger 2, second cooler 3, A cooler 4, an internal combustion engine 5, the LNG pump 1 is connected to the a port of the gas-liquid heat exchanger 2 through a pipe, and the b port of the gas-liquid heat exchanger 2 is connected to the second cooler 3 through a pipe g interface, the h interface of the second cooler 3 is connected to the m interface of the first cooler 4 through a pipe, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap