Preparation process of a wear-resistant and anti-fading knitted fabric

A knitted fabric and preparation technology, which is applied in knitting, warp knitting, weft knitting, etc., can solve the problems that the wear resistance cannot meet the requirements, and achieve the effect of preventing clothing from wearing and tearing, preventing discoloration, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

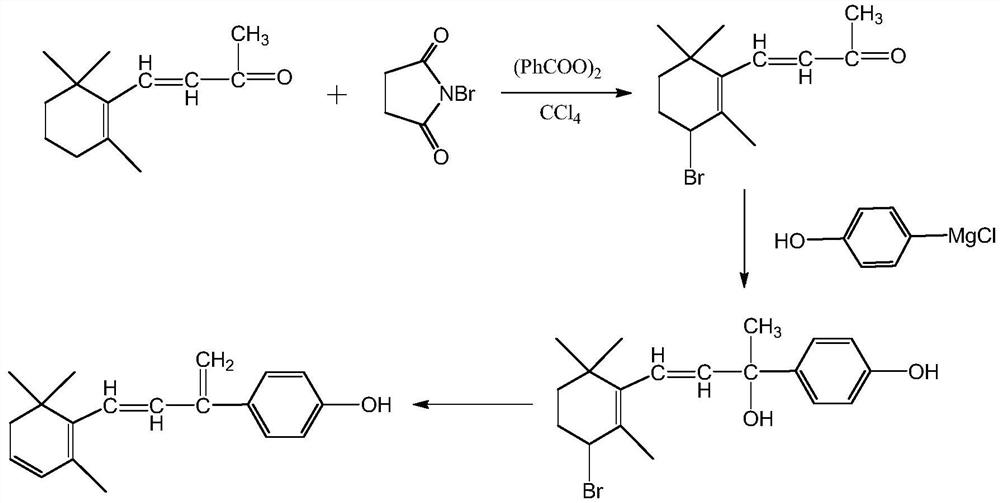

[0023] The specific preparation process of wear-resistant fiber is as follows:

[0024] ① Weigh 192g of β-ionone and 800mL of carbon tetrachloride solution into the reaction vessel at the same time, then add 187g of N-bromosuccinimide and 120g of benzoyl peroxide into it, heat up to 120-130°C and reflux for 20 -22h, then the product obtained is subjected to underpressure distillation to obtain light yellow bromoionone solution;

[0025] ② Add 24g of magnesium chips into 500mL of ether, and add 128g of 4-chlorophenol to it at the same time, at this time, the ether boils slightly until the ether boils off, and then distills under reduced pressure to obtain hydroxymagnesium chloride;

[0026] ③Add 152g of hydroxymagnesium chloride to 1000mL of ether, then add 272g of the bromoionone solution prepared in step ① to it, stir and react at room temperature for 2-3h, then evaporate to remove the solvent, and add the product to ethyl acetate Carrying out extraction, carrying out vacuum...

Embodiment 2

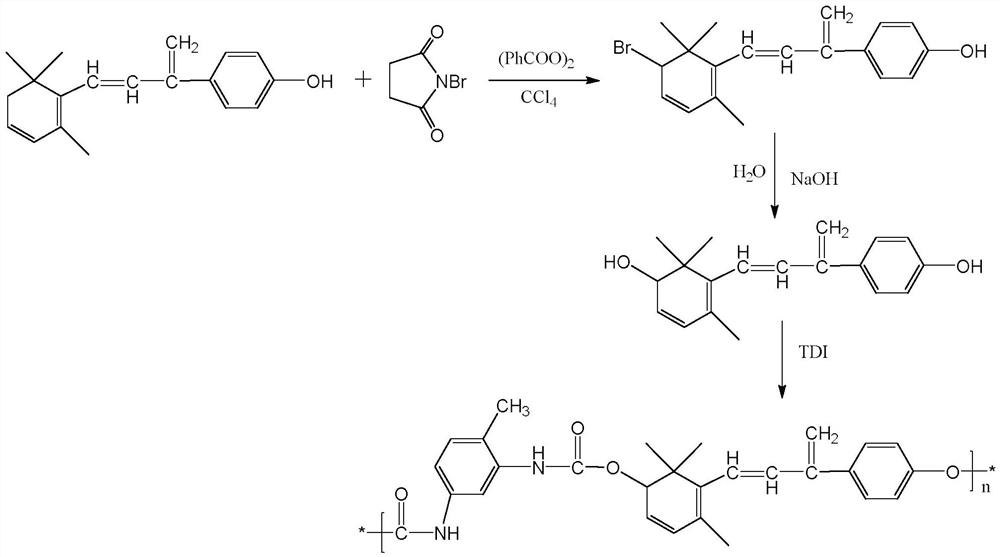

[0034] The specific preparation process of wear-resistant fiber is as follows:

[0035] 1. Add 24g of magnesium chips into 500mL of ether, and add 128g of 4-chlorophenol to it at the same time. At this time, the ether boils slightly until the ether boils and stops, and then distills under reduced pressure to obtain magnesium hydroxychloride;

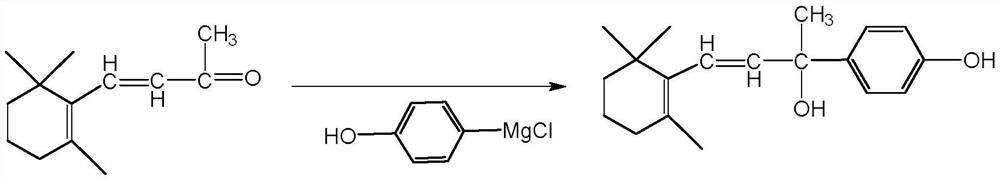

[0036] ②Add 152g of hydroxymagnesium chloride to 1000mL of ether, then add 192g of β-ionone into it, stir and react at room temperature for 2-3h, then evaporate to remove the solvent, add the product into ethyl acetate for extraction, and extract the obtained The oil phase is subjected to vacuum distillation to obtain unsaturated phenol, and the reaction structure is as follows;

[0037]

[0038] ③ Add 1kg of the unsaturated phenol prepared in step ② into 10L of ethanol, stir and mix evenly, add 132g of potassium hydroxide to it, stir to dissolve, then heat up to 120-130°C and reflux for 15-16h, and then evaporate the product to remov...

Embodiment 3

[0045] A preparation process of wear-resistant and anti-fading knitted fabric, the specific preparation process is as follows:

[0046] In the first step, add 100g of cotton fiber to 500mL of 2% sodium hydroxide solution, heat up to 50-60°C and cook for 72 hours, then wash until neutral, dry and mix with the wear-resistant fiber filament prepared in Example 1 Blending according to the mass ratio of 1:4.6 to obtain composite yarn;

[0047] In the second step, add 105g detergent, 23g dispersant, 10g weak acid dye and 45g water into the dye vat at the same time, then adjust the temperature of the dye vat to 50-55°C, and then add 100g of the composite yarn prepared in the first step Dip dyeing in the dye vat for 30-40min, then raise the temperature to 90-100°C, add 12g of ammonium sulfate to it, then dip-dye for 20-30min, then wash in hot water at 50-60°C, and dry the washed composite yarn Then weave to form a knitted fabric;

[0048] The 3rd step, chitosan is added in acetic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com