Preparation method of polyamide flame-retardant material for laser sintering

A flame retardant material and laser sintering technology, applied in the field of additive manufacturing, can solve the problems of reducing the mechanical and mechanical properties of the workpiece and the effective printing height, reducing the fluidity of the powder, limiting the application, etc. Protect, improve fluidity and stability, reduce the effect of volatile matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

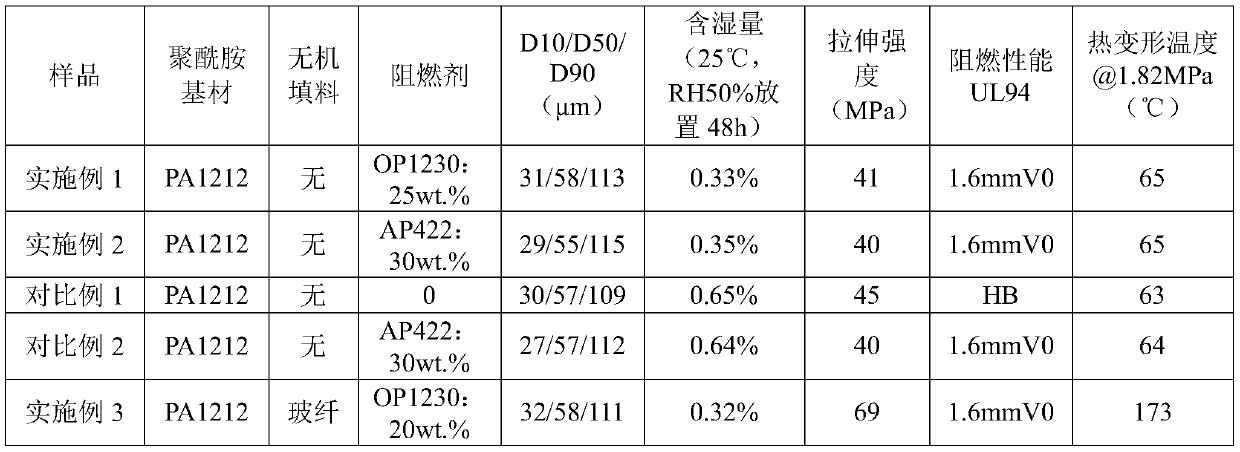

Embodiment 1

[0024] Dry 7.15kg PA1212 resin, 2.5kg flame retardant OP1230, 300g silane grafted polyethylene (sxPE), 30g2,6-di-tert-butyl-4-methyl-phenol, 20g2,2'-ethylenebis (4,6-di-tert-butylphenyl) fluorophosphite was blended and extruded with a twin-screw extruder to obtain PA1212 flame-retardant particles, and the prepared PA1212 flame-retardant particles were cryogenically crushed, Prepare PA1212 flame-retardant powder, dry and sieve to obtain PA1212 flame-retardant powder with a particle size range of 30-100 microns; take 5.97kg of PA1212 flame-retardant powder with a particle size range of The derivative modified silicon dioxide is evenly mixed to prepare PA1212 flame retardant powder material for selective laser sintering.

Embodiment 2

[0026] The dried 6.65kgPA1212 resin, 3kg flame retardant AP422, 300g silane grafted polyethylene (sxPE), 30g2,6-di-tert-butyl-4-methyl-phenol, 20g2,2'-ethylenebis( 4,6-di-tert-butylphenyl) fluorophosphite is blended and extruded with a twin-screw extruder to obtain PA1212 flame-retardant particles, and the prepared PA1212 flame-resistant particles are cryogenically crushed to produce Obtain PA1212 flame retardant powder, dry and sieve to obtain PA1212 flame retardant powder with a particle size range of 30-100 microns; take 5.97kg of PA1212 flame retardant powder with a particle size range of The modified silicon dioxide is uniformly mixed to prepare PA1212 flame retardant powder material for selective laser sintering.

Embodiment 3

[0032]Dry 5.65kg PA1212 resin, 2kg flame retardant OP1230, 2kg glass fiber with a length of 1mm, 300g silane grafted polyethylene (sxPE), 30g2,6-di-tert-butyl-4-methyl-phenol, 20g2,2 '-Ethylene bis(4,6-di-tert-butylphenyl) fluorophosphite is blended and extruded with a twin-screw extruder to obtain PA1212 flame-retardant particles, and the prepared PA1212 flame-retardant Combustible particles are subjected to cryogenic crushing to obtain PA1212 flame-retardant powder, dried and sieved to obtain PA1212 flame-retardant powder with a particle size range of 30-100 microns; take 5.97kg of PA1212 flame-retardant powder with a particle size range of above, 30g with a particle size of 20nm And the silicon dioxide whose surface is modified by silazane derivatives is uniformly mixed to prepare PA1212 glass fiber flame-retardant powder material for selective laser sintering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com