High heat resistant epoxy resin and preparation method thereof

An epoxy resin, high heat resistance technology, applied in the field of polymer fine chemicals, can solve the problems of poor compatibility and difficult to meet the manufacturability, and achieve the effect of improving toughness, solving manufacturability problems, and improving the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of high heat resistance epoxy resin, concrete steps are as follows:

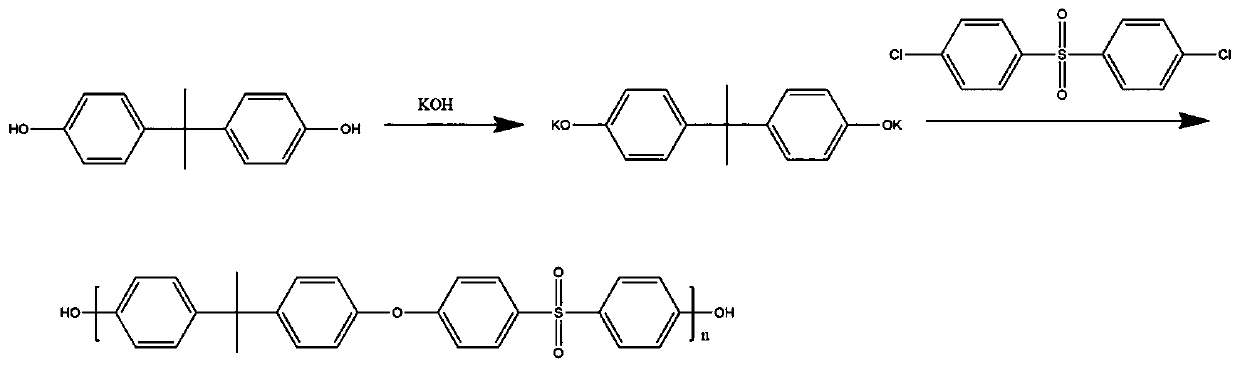

[0023] (1) Preparation of hydroxyl-terminated oligopolyethersulfone

[0024] Dissolve 4mol bisphenol A and 3mol 4,4'-dichlorodiphenylsulfone in 2000g ethanol with a volume fraction of 90%, add 5.4molKOH, reflux and stir for 5h, then add excess HCl to neutralize, then add 2000g distilled water to The precipitate is precipitated, and the precipitate is washed with water, washed with 50% ethanol aqueous solution, and then dried to obtain a hydroxyl-terminated oligopolyethersulfone with a degree of polymerization of 6;

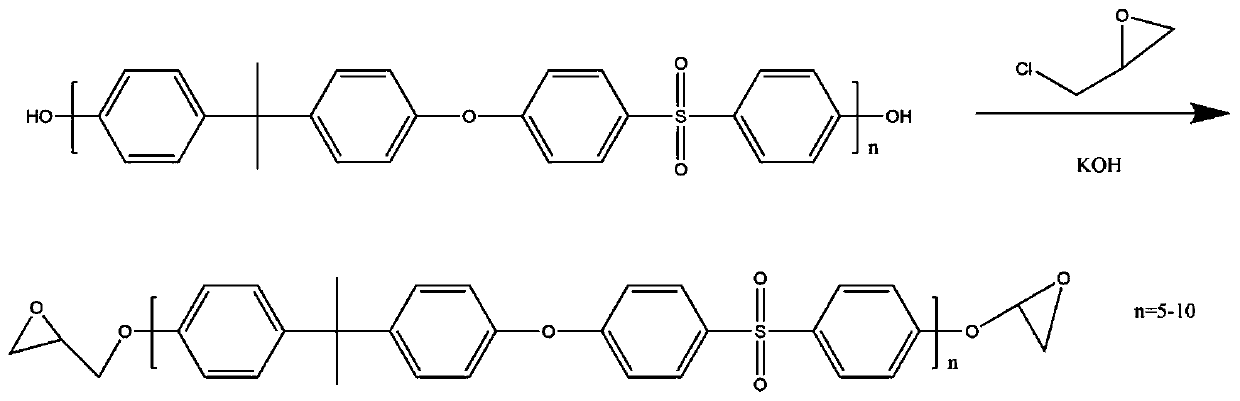

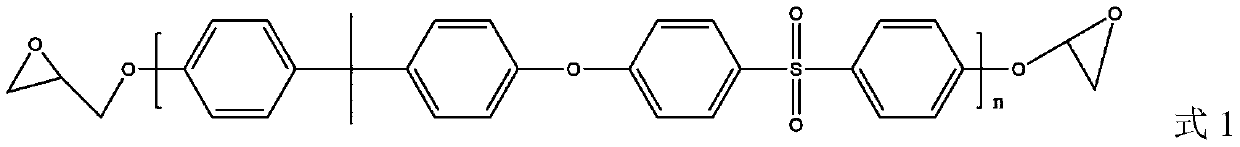

[0025] (2) Preparation of epoxy-terminated modified oligopolyethersulfone

[0026] Dissolve 50 g of the hydroxyl-terminated oligopolyethersulfone obtained in step (1) in 200 g of ethanol with a volume fraction of 95%, add 20 g of 40 wt % KOH aqueous solution, add 10 g of epichlorohydrin dropwise within 2 h under reflux stirring, and drop After the addition i...

Embodiment 2

[0030] A kind of preparation method of high heat resistance epoxy resin, concrete steps are as follows:

[0031] (1) Preparation of hydroxyl-terminated oligopolyethersulfone

[0032] Dissolve 5 mol of bisphenol A and 4 mol of 4,4'-dichlorodiphenyl sulfone in 2000 g of ethanol with a volume fraction of 95%, add 8 mol of KOH, reflux and stir for 4.5 hours, then add excess HCl to neutralize, then add 2000 g of distilled water until precipitation occurs. The precipitate is washed with water, washed with 50% ethanol aqueous solution, and then dried to obtain a hydroxyl-terminated oligopolyethersulfone with a degree of polymerization of 8;

[0033] (2) Preparation of epoxy-terminated modified oligopolyethersulfone

[0034] Dissolve 50 g of the hydroxyl-terminated oligopolyethersulfone obtained in (1) in 200 g of ethanol with a volume fraction of 95%, add 17.5 g of 40 wt % KOH aqueous solution, add 10 g of epichlorohydrin dropwise within 2 h under reflux stirring, and dropwise add ...

Embodiment 3

[0038] A kind of preparation method of high heat resistance epoxy resin, concrete steps are as follows:

[0039] (1) Preparation of hydroxyl-terminated oligopolyethersulfone

[0040] Dissolve 6 mol of bisphenol A and 5 mol of 4,4'-dichlorodiphenyl sulfone in 2000 g of ethanol with a volume fraction of 90%, add 11 mol of KOH, reflux and stir for 5.5 hours, then add excess HCl to neutralize, then add 2000 g of distilled water until precipitation occurs. The precipitate is washed with water, washed with 50% ethanol aqueous solution, and then dried to obtain hydroxyl-terminated oligopolyethersulfone with a degree of polymerization of 10;

[0041] (2) Preparation of epoxy-terminated modified oligopolyethersulfone

[0042] Dissolve 50g of the hydroxyl-terminated oligopolyethersulfone obtained in (1) in 200g of ethanol with a volume fraction of 95%, add 20g of 40wt% KOH aqueous solution, add 10g of epichlorohydrin dropwise within 2 hours under reflux and stirring, and after the drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com