Two-dimensional bismuth vanadate/graphene/carbon nitride composite material as well as preparation method and application thereof

A composite material and carbon nitride technology, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve problems such as high recombination rate of photogenerated charges, low quantum yield, and limited applications , to achieve the effect of improving catalytic ability, simple preparation method, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

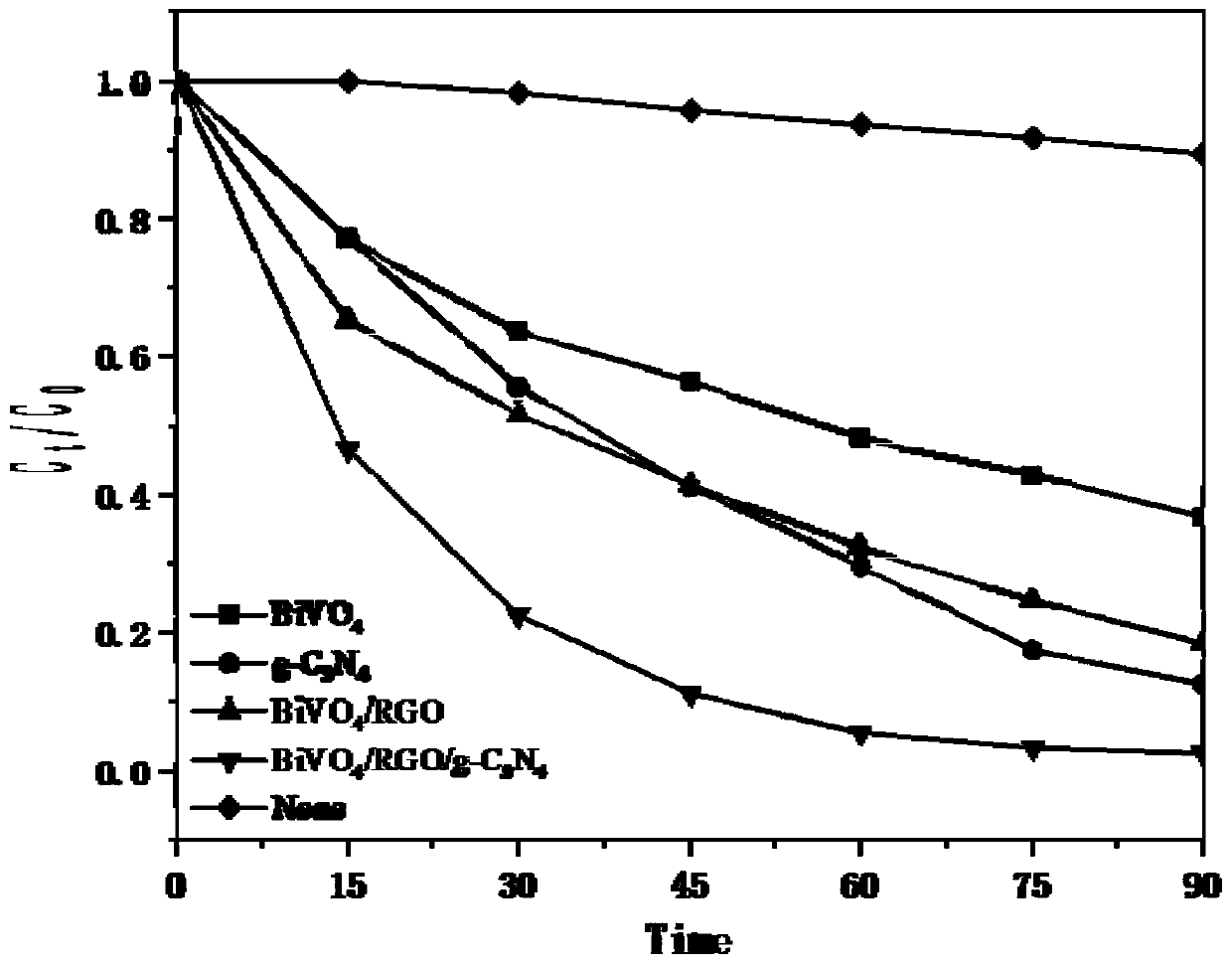

Embodiment 1

[0030]Weigh 20g of urea into a semi-closed crucible and place it in a muffle furnace. At a heating rate of 5°C / min, it was raised to 550°C and kept for 4 hours, and finally a light yellow g-C was obtained 3 N 4 powder. Add 0.15g of this sample to 150mL 10mg·L -1 In the methylene blue solution, ultrasonic and stirred in the dark for 30min to reach adsorption equilibrium. Irradiate under 300W xenon lamp light source, calculate its degradation efficiency.

Embodiment 2

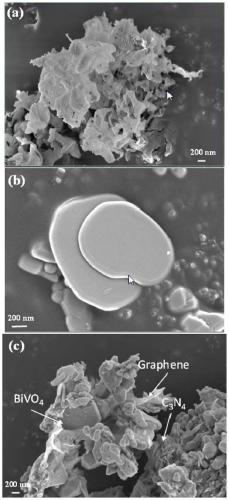

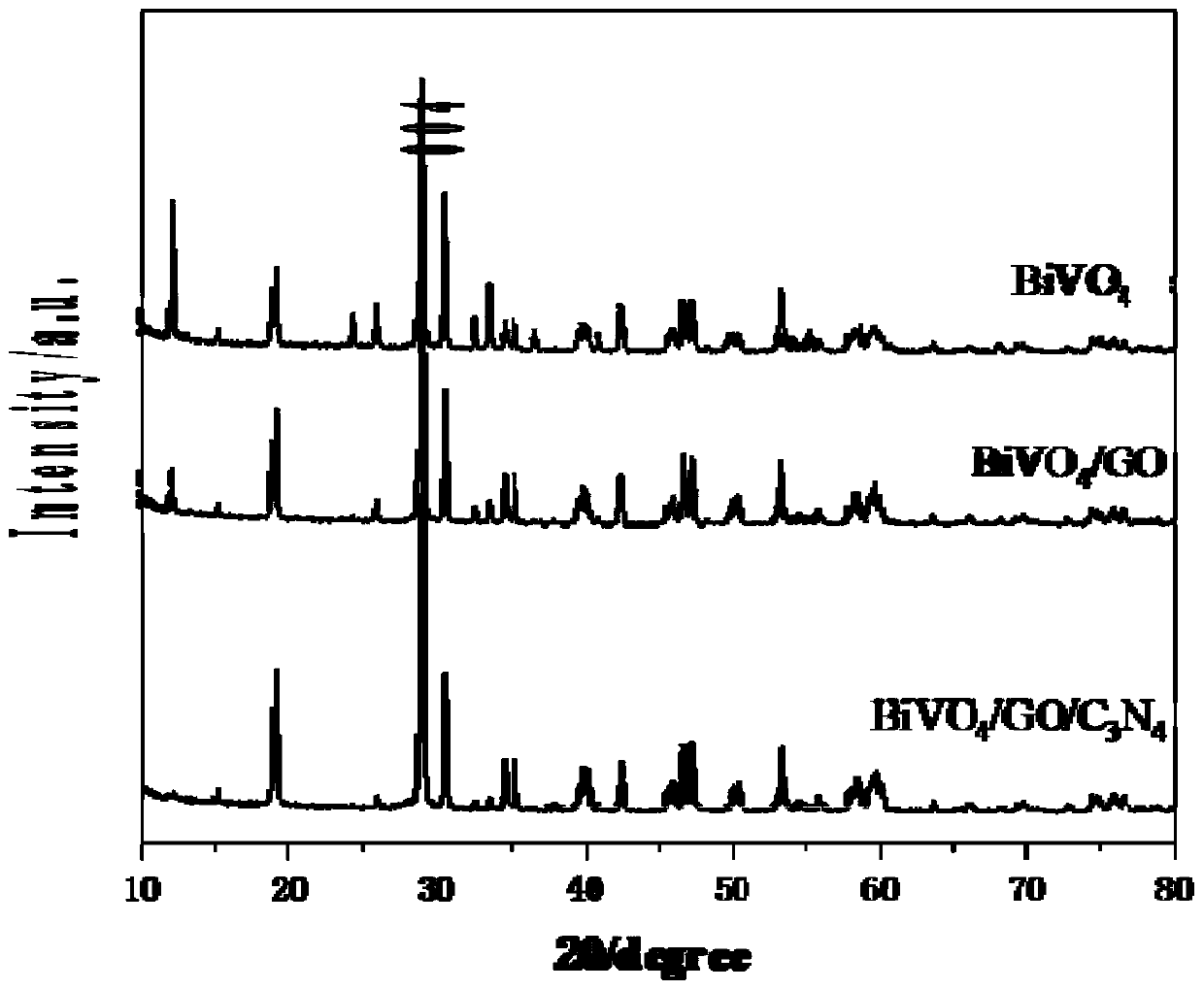

[0032] Weigh 158mg BiCl 3 Add 50 mL of deionized water and stir to form a white suspension. Weigh 59mg of NH 4 VO 3 The powder was slowly added to the above solution, the solution turned from white to yellow, and the stirring was continued for 30 min. Then add 0.3mL 1M ethanolamine solution, 3.16mL 1g·L -1 GO aqueous solution and the g-C obtained in embodiment 1 of 0.064g 3 N 4 Solid, ultrasonic 30min, mix well. The solution was poured into a 100mL polytetrafluoroethylene-lined autoclave, and subjected to hydrothermal reaction at 160°C for 12h. Centrifuge, wash with absolute ethanol and deionized water, and dry to collect the solid. Add 0.15g of this sample to 150mL 10mg·L -1 In the methylene blue solution, ultrasonic and stirred in the dark for 30min to reach adsorption equilibrium. Irradiate under 300W xenon lamp light source, calculate its degradation efficiency.

Embodiment 3

[0034] Weigh 166.4mg BiCl 3 Add 55 mL of deionized water and stir to form a white suspension. Weigh 61mg of NH 4 VO 3 The powder was slowly added to the above solution, the solution turned from white to yellow, and the stirring was continued for 25 min. Then add 0.3mL 1M ethanolamine solution, 3.16mL 1.1g·L -1 GO aqueous solution and the g-C obtained in embodiment 1 of 0.064g 3 N 4 Solid, ultrasonic 30min, mix well. The solution was poured into a 100mL polytetrafluoroethylene-lined autoclave, and subjected to hydrothermal reaction at 170°C for 14h. Centrifuge, wash with absolute ethanol and deionized water, and dry to collect the solid. Add 0.15g of the sample to 150mL10mg·L -1 In the methylene blue solution, ultrasonic and stirred in the dark for 30min to reach adsorption equilibrium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com