Electrochemical ceramic membrane oxygen generating system with self-heating function

An oxygen production system and self-heating technology, applied in inorganic chemistry, chemical instruments and methods, oxygen/ozone/oxide/hydroxide, etc., can solve the problem of high use cost, low oxygen purity, and inability to produce Use and other problems to achieve the effect of saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

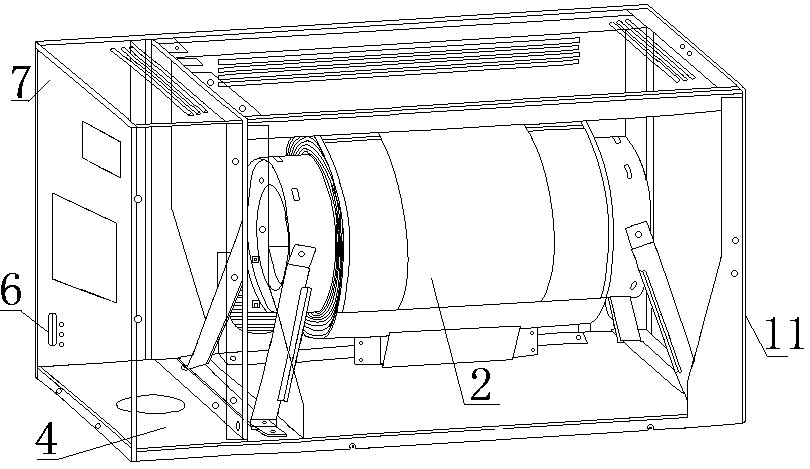

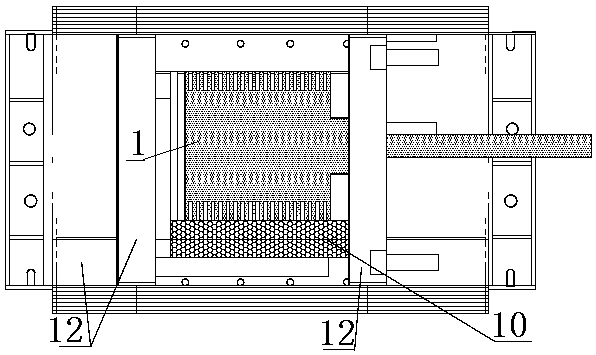

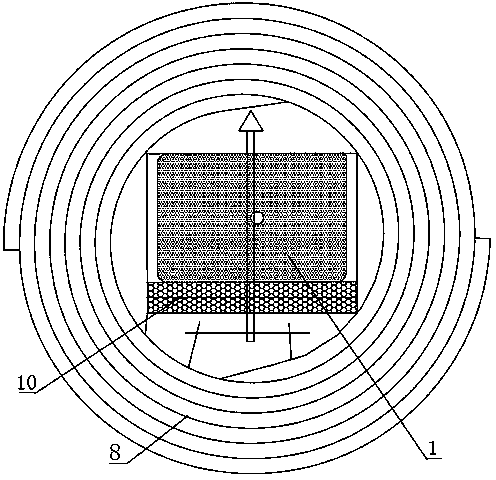

[0023] As shown in the figure, the electrochemical ceramic membrane oxygen production system with self-heating function of the present invention is a ceramic membrane module 1 formed by stacking multiple self-heating electrochemical ceramic membranes, and a thermal management system that plays the roles of heating management, heat preservation, and thermal cycle. The system is combined into an electrochemical ceramic membrane oxygen production module 2, which is equipped with a control module 3, a power module 4, a detection module 5, a switch and display module 6, an intake fan and a chassis 7 to form an electrochemical ceramic with self-heating function. Membrane oxygen generation system: the air intake fan inputs fresh air, the air is preheated by double-helix heat exchanger 8, and after being heated to 800°C, it is evenly blown to the stacked ceramic membrane modules 1 through air distributor 10, and then automatically Separation of heated electrochemical ceramic membranes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com