A kind of polymer lithium ion battery and preparation method of polymer lithium ion battery

A lithium-ion battery and polymer technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of unable to prevent side reactions, diaphragm shrinkage, short-circuits, etc. of lithium-ion batteries, so as to increase production processes and improve safety. The effect of sex, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

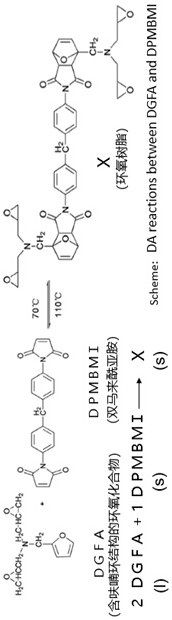

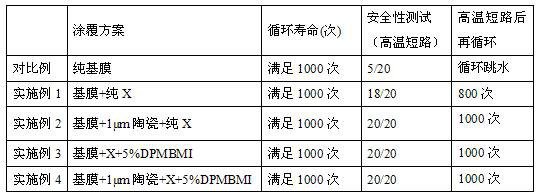

[0017] Embodiment 1: This embodiment describes a polymer lithium ion battery, including a positive electrode, a negative electrode, a diaphragm, an electrolyte, a tab, an aluminum plastic film, etc., using the product of the Diels-Alder reaction, the combination of the product and the raw material, The combination of product and ceramic or the combination of product, raw material and ceramic is used as the coating layer of the separator, the material of the coating layer is selected to be able to introduce Diels-Alder reaction (Diels-Alder reaction) to polymer lithium ions in the battery chemistry.

specific Embodiment approach 2

[0018] Embodiment 2: In the polymer lithium ion battery described in Embodiment 1, the raw materials are conjugated dienes and substituted olefins, both of which can undergo Diels-Alder reaction, and the two raw materials are preferably one: Solid state, one is liquid state, and the reaction temperature range is 60~130℃.

specific Embodiment approach 3

[0019] Embodiment 3: The polymer lithium ion battery described in Embodiment 2, the raw material is any one of the following three types: (1) cyclopentadiene and pyridyl thiocarbamate; (2) Furan-based epoxy resin and maleic anhydride; (3) Furfuryl amine and bisphenol A epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com