Microcapsule type phase-change energy-storage material and preparation method and application thereof

A phase change energy storage material and a phase change material technology, applied in the field of microcapsule type phase change energy storage materials, can solve the problems of poor shell compactness, low strength and toughness, easy rupture of the capsule wall, etc. High coverage, overcoming the effect of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

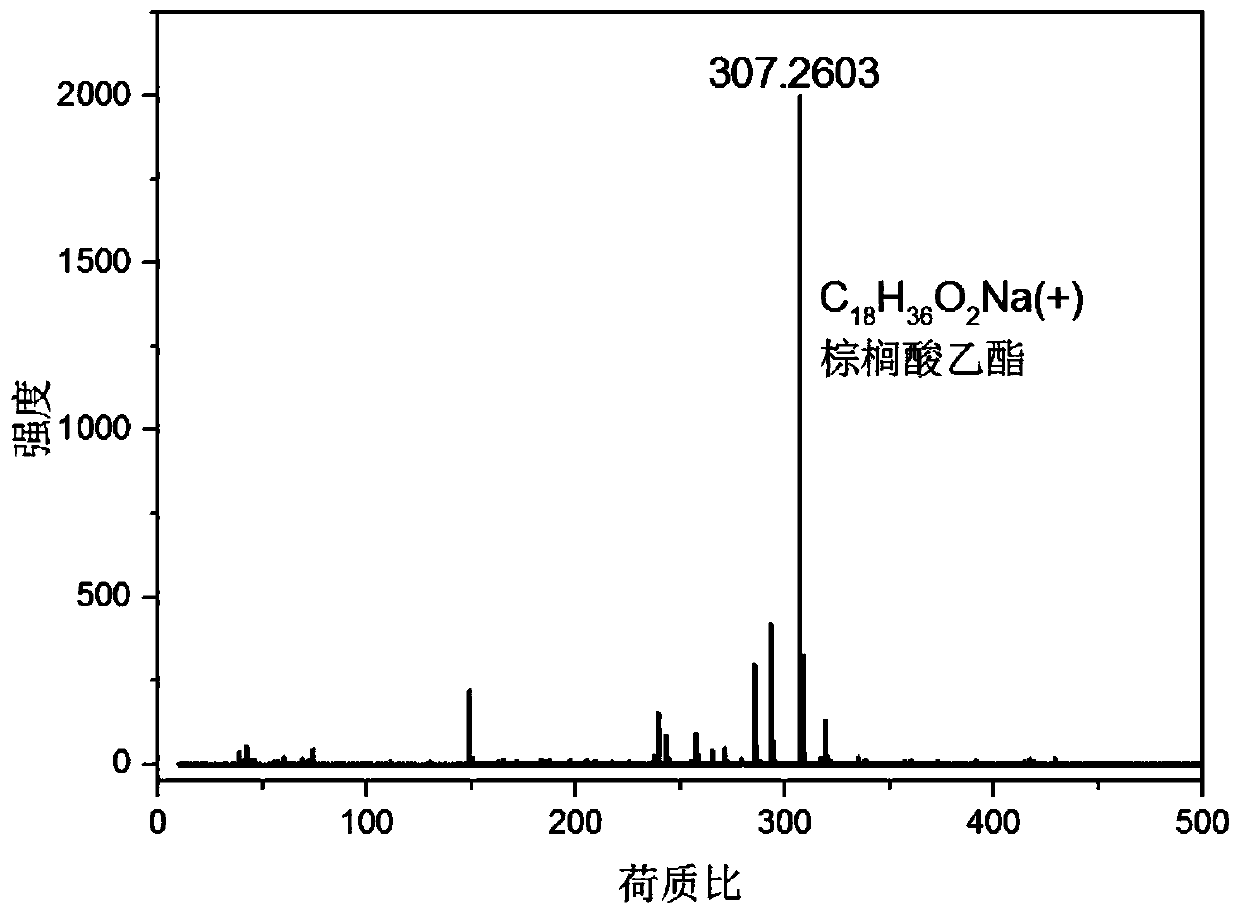

[0037] The preparation of embodiment 1 fatty acid ester

[0038] Taking ethyl palmitate as an example, add 100ml of DMF to a three-neck flask, stir slowly, control the temperature of 20% ice-cold saline to 0°C, add 20ml of ethanol, and stir to dissolve. Slowly add 500 μL of thionyl chloride dropwise, and at the same time slowly add 15ml of palmitoyl chloride, control the dropwise addition to be completed within 2-3 hours, while keeping the temperature at 0°C, and react for 10 hours. After the reaction is completed, the solvent is distilled off, and finally a colorless oil is obtained , adding acetone for recrystallization to obtain a white crystalline powder. figure 1 Mass spectrum of the resulting ethyl palmitate product.

Embodiment 2

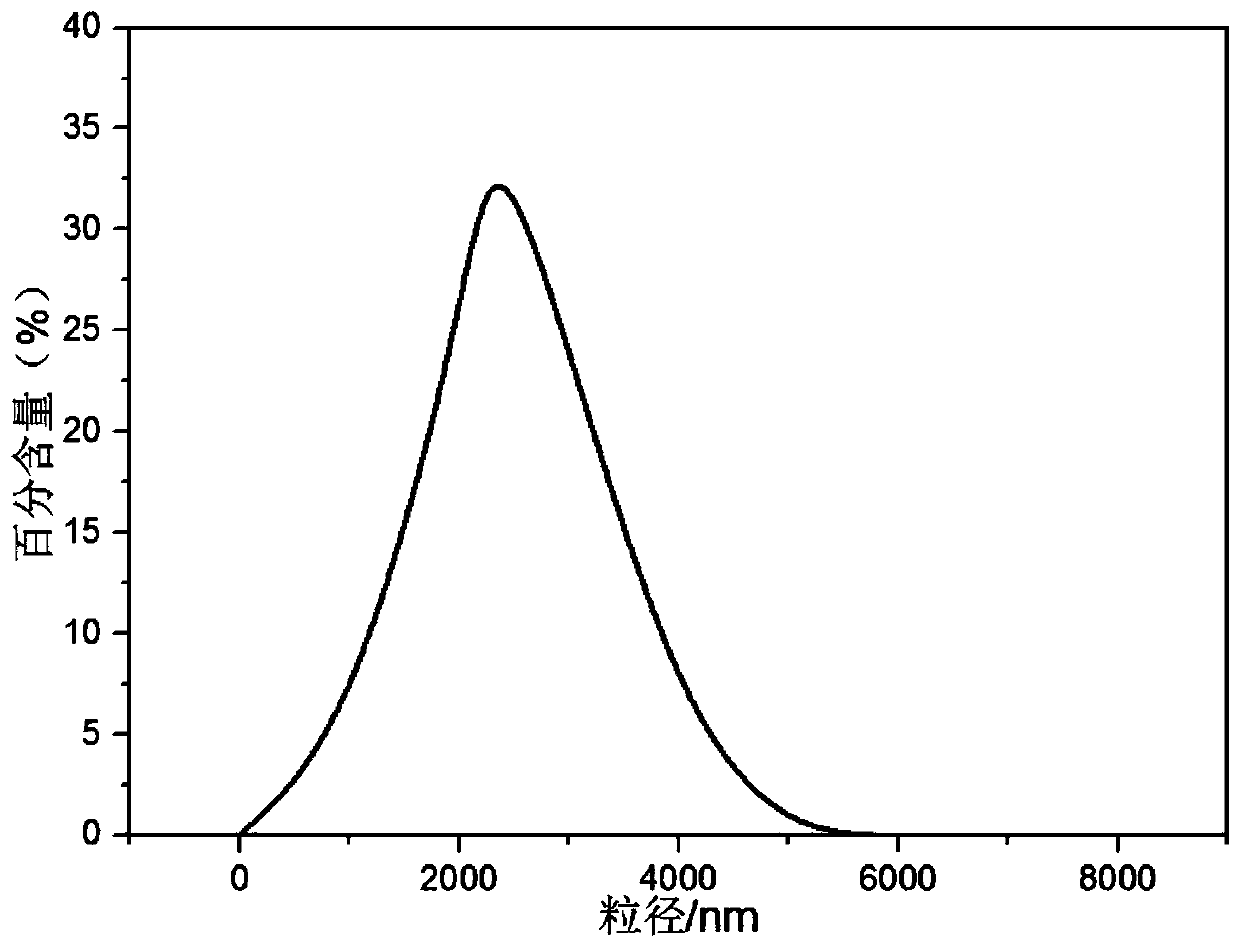

[0039] The emulsification of embodiment 2 phase change core material

[0040] Take ethyl palmitate phase change core material as an example, weigh 25g ethyl palmitate, 20g sodium oleate, and 200ml water in a three-necked flask, heat and stir at room temperature for 45min at a speed of 1000r / min to form a uniform white lotion.

Embodiment 3

[0041] The preparation of embodiment 3 PEI microcapsules

[0042] Add 40% PEI aqueous solution to the emulsion described in Example 2, maintain a stirring speed of 1000 r / min, and react at room temperature for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com