A kind of macroporous polymethacrylimide foam and preparation method thereof

A technology of polymethacrylimide and foam, which is applied in the field of large-pore polymethacrylimide foam and its preparation, to achieve the effects of good overall mechanical properties, large amount of glue absorption, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

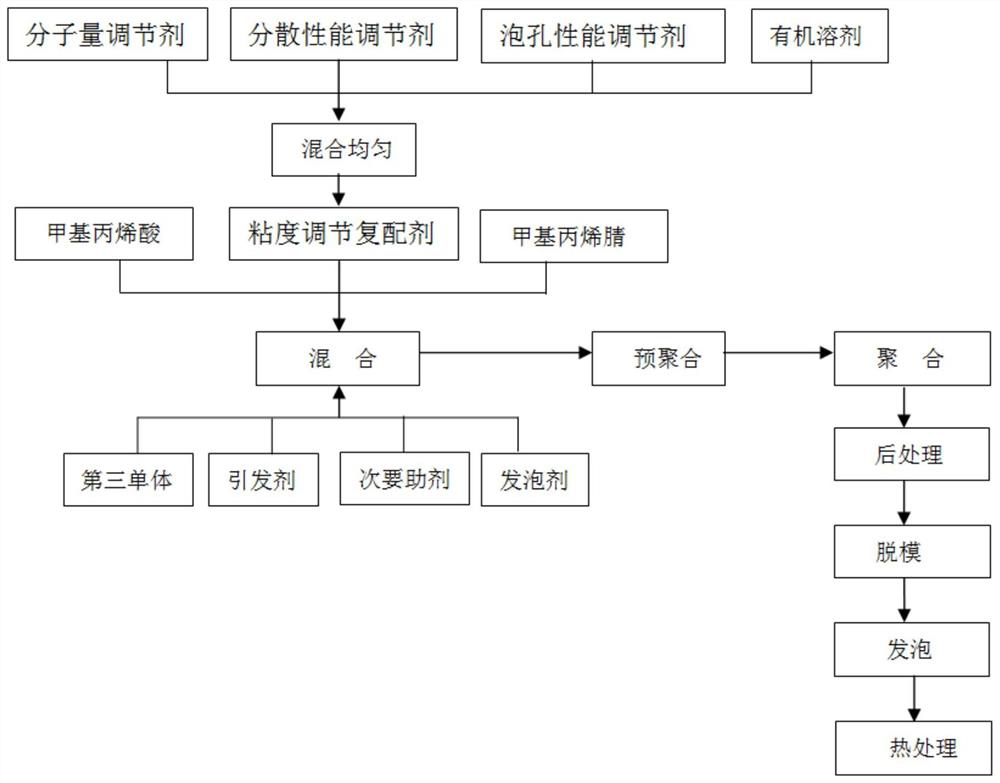

[0074] (2) The preparation method provided in the present invention is described in detail as follows:

[0075] The material mixing process is divided into two steps:

[0076] Step S1: Accurately weigh the amount of the organic solvent, molecular weight modifier, dispersion performance modifier, and cell performance modifier in the viscosity-adjusting compound, and mix them uniformly within the range of 20-32°C, and observe that there is no precipitation, separation layers etc.

[0077] Step S2, accurately weigh the components such as (meth)acrylic acid, (meth)acrylonitrile, initiator, foaming agent, viscosity adjusting compound, moisture absorbent, third monomer and secondary additives , Mix well and dissolve completely at a constant temperature of 15-35°C. If there is precipitation or insoluble matter, it is necessary to filter the precipitate or insoluble matter.

[0078] The mixed material liquid obtained after mixing the materials uniformly undergoes a polymerization re...

Embodiment 1

[0083] According to parts by weight: 60 parts of methacrylic acid, 60 parts of methacrylonitrile, 1.5 parts of propyl methacrylate, 0.8 parts of initiator, 5 parts of foaming agent, 5 parts of viscosity adjusting compounding agent, 3 parts of water absorption agent, 0.06 parts of antioxidant 1076, mixed evenly, and filtered to obtain a mixed material liquid; wherein, the viscosity adjusting compound was previously composed of isooctyl mercaptopropionate, N-phenylmaleimide, methacrylic acid hydroxyl Propyl ester and ethanol are mixed, and the weight ratio of the four substances is 5:2:3:5; the initiator is mixed with lauryl peroxide and tert-butyl peroxybenzoate, and the weight ratio of the two It is 3:5; the foaming agent is a mixture of propanol and butanol, and the weight ratio of the two is 2:3; the moisture absorbent is molecular sieve.

[0084] After reacting the mixture solution in a water bath at 31°C for 350h, heat treatment at 50°C for 100h to obtain a prepolymer;

...

Embodiment 2

[0088] According to parts by weight: 70 parts of methacrylic acid, 70 parts of methacrylonitrile, 1.5 parts of acrylamide, 0.9 parts of initiator, 4 parts of foaming agent, 4 parts of viscosity adjusting compounding agent, 2 parts of moisture absorbent, 0.03 Dodecyl benzene sulfonate, mixed evenly, and filtered to obtain a mixed material liquid; wherein, the viscosity adjusting compound was previously composed of dodecyl mercaptan, triallyl isocyanurate, hydroxyethyl acrylate It is made by mixing ester and propanol, and its weight ratio is 5:2:5:6; the initiator is made by mixing dicumyl peroxide and peroxydicarbonate, and the weight ratio of the two is 2:3 ; The foaming agent is formed by mixing ethanol and butanol, and the weight ratio of the two is 1:1; the moisture absorbing agent is activated carbon.

[0089] After the mixture solution was reacted in a water bath at 33°C for 280h, it was heat-treated at 90°C for 90h to obtain a prepolymer;

[0090] The temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com