Thermosensitive hydrogel adsorbent and preparation and application methods thereof

A temperature-sensitive hydrogel and adsorbent technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve single adsorption of rare earth metal ions, unenriched recovery research, etc. problems, achieve high adsorption rate, save resources, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

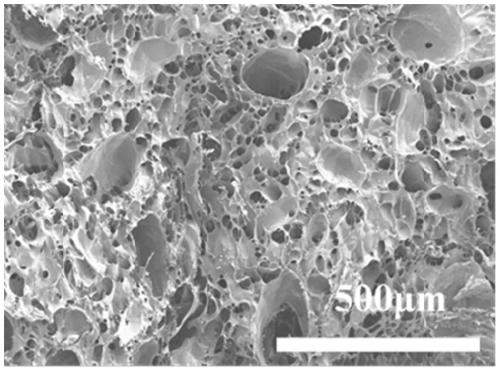

[0049] Get 0.6433g NIPAM, 0.066g MA, 0.028g crosslinking agent MBAM, 0.070g initiator APS and join in the sample bottle, add 9.35mL deionized water to dissolve, then add 0.65mL 1g / L GO solution and stir, pass After entering argon for 20 minutes, 50 μL TEMED was added, and after standing at 25°C for 3 minutes, it was transferred to a -25°C refrigerator and sealed for reaction for 24 hours. After the reaction was completed, the hydrogel was thawed at room temperature, cut into pieces, soaked, and vacuum-dried to obtain the adsorbent. The SEM photo is as follows: figure 1 As shown, the hydrogel adsorbent has an obvious hierarchical network structure inside, which is interconnected by large pores with a pore size of 10-100 μm and small pores of 1-50 μm.

[0050] The rare earth metal salt LaCl 3 Prepare an aqueous solution with a concentration of 360 mg / L and pH=5.0 for later use.

[0051] Mix 0.055g of the above-mentioned prepared hydrogel adsorbent with 20mL of the above-mentio...

Embodiment 2

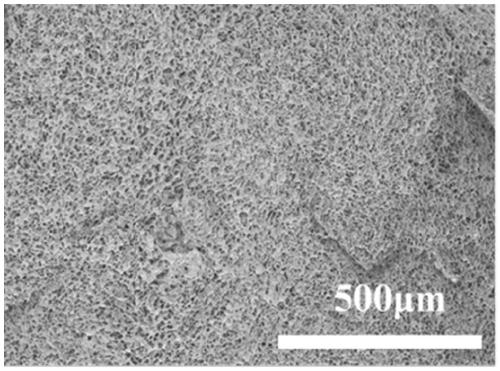

[0059] Get 0.6433g NIPAM, 0.066g MA, 0.028g crosslinking agent MBAM, 0.070g initiator APS and join in the sample bottle, add 9.35mL deionized water to dissolve, then add 0.65mL 1g / L GO solution and stir, pass After entering argon for 20 minutes, add 50 μL TEMED, react at 25°C for 24 hours, cut the hydrogel into pieces, soak, and vacuum-dry to obtain the adsorbent. The SEM photo is as follows: figure 2 As shown, the pore size of the hydrogel is mainly continuously distributed between 0.05 and 100 μm.

[0060] The rare earth metal salt LaCl 3 Prepare an aqueous solution with a concentration of 360 mg / L and pH=5.0 for later use.

[0061] Mix 0.055g of the prepared hydrogel adsorbent with 20mL of the above solution, place it at room temperature at 25°C for 12h, and then use ICP-MS to measure the content of lanthanum ions in the aqueous solution before and after adsorption. After measurement and calculation, its equilibrium adsorption capacity is 20.29±0.395mg / g.

[0062] Take ...

Embodiment 3

[0064] Get 0.6433g NIPAM, 0.033g MA, 0.028g crosslinking agent MBAM, 0.070g initiator APS and join in the sample bottle, add 9.35mL deionized water to dissolve, then add 0.65mL 1g / L GO solution and stir, pass After entering argon for 20 minutes, add 50 μL TEMED, react at 25° C. for 3 minutes, transfer to a refrigerator at -25° C., seal and react for 24 hours. After the reaction is completed, the freeze-polymerized hydrogel is cut into pieces, soaked, and vacuum-dried to obtain the adsorbent.

[0065] The rare earth metal salt LaCl 3 Prepare an aqueous solution with a concentration of 360 mg / L and pH=5.0 for later use.

[0066] Mix 0.055g of the prepared hydrogel adsorbent with 20mL of the above solution, place it at room temperature at 25°C for 12h, and then use ICP-MS to measure the content of lanthanum ions in the aqueous solution before and after adsorption. After measurement and calculation, its equilibrium adsorption capacity is 19.53±0.403mg / g.

[0067] Take out the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com