Fiber-reinforced resin based composite core of overhead wire and preparation method of fiber-reinforced resin based composite core

A fiber-reinforced resin and overhead line technology, which is applied in the field of power transmission wires, can solve problems such as poor toughness, achieve the effects of improving high temperature resistance, excellent toughness and impact resistance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

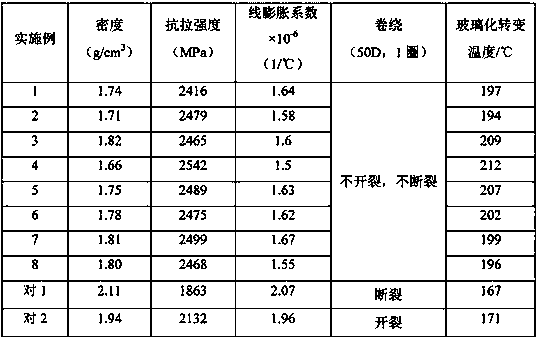

Examples

Embodiment 1

[0034] A fiber-reinforced resin-based composite core for overhead lines, comprising an inner core and an outer core, the outer core is wrapped around the inner core, the inner core is carbon fiber, and the outer core is glass fiber, The inner core and the outer core are formed by heating and curing modified epoxy resin, and the weight percentages of carbon fiber, glass fiber and modified epoxy resin in the composite core are 30%, 35% and 35%;

[0035] Described modified epoxy resin is formulated from the raw materials of following parts by weight:

[0036] 50 parts of epoxy resin, 20 parts of styrene-maleic anhydride copolymer, 15 parts of epoxy lignin, 40 parts of curing agent and 20 parts of thinner.

[0037] The carbon fiber density is 1.6-2.0g / cm 3 , tensile strength 4.5-5.5GPa, elongation at break 1.5-2.1%, resistivity (1.5-2)×10 -3 Ω·cm.

[0038] Described glass fiber density is 2.2-2.8g / cm 3 , tensile strength 1.8-3.5GPa, elongation at break 3.4-5%, resistivity (1-1...

Embodiment 2

[0045] A fiber-reinforced resin-based composite core for overhead lines, comprising an inner core and an outer core, the outer core is wrapped around the inner core, the inner core is carbon fiber, and the outer core is glass fiber, The inner core and the outer core are heat-cured and molded by modified epoxy resin, and the weight percentages of carbon fiber, glass fiber and modified epoxy resin in the composite core are 35%, 31% and 34%;

[0046] Described modified epoxy resin is formulated from the raw materials of following parts by weight:

[0047] 55 parts of epoxy resin, 25 parts of styrene-maleic anhydride copolymer, 20 parts of epoxy lignin, 50 parts of curing agent and 15 parts of thinner.

[0048] The carbon fiber density is 1.6-2.0g / cm 3 , tensile strength 4.5-5.5GPa, elongation at break 1.5-2.1%, resistivity (1.5-2)×10 -3 Ω·cm.

[0049] Described glass fiber density is 2.2-2.8g / cm 3 , tensile strength 1.8-3.5GPa, elongation at break 3.4-5%, resistivity (1-1.4)×...

Embodiment 3

[0056] A fiber-reinforced resin-based composite core for overhead lines, comprising an inner core and an outer core, the outer core is wrapped around the inner core, the inner core is carbon fiber, and the outer core is glass fiber, The inner core and the outer core are formed by heating and curing modified epoxy resin, and the weight percentages of carbon fiber, glass fiber and modified epoxy resin in the composite core are 35%, 25% and 40%;

[0057] Described modified epoxy resin is formulated from the raw materials of following parts by weight:

[0058] 60 parts of epoxy resin, 28 parts of styrene-maleic anhydride copolymer, 18 parts of epoxy lignin, 45 parts of curing agent and 20 parts of thinner.

[0059] The carbon fiber density is 1.6-2.0g / cm 3 , tensile strength 4.5-5.5GPa, elongation at break 1.5-2.1%, resistivity (1.5-2)×10 -3 Ω·cm.

[0060] Described glass fiber density is 2.2-2.8g / cm 3 , tensile strength 1.8-3.5GPa, elongation at break 3.4-5%, resistivity (1-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com