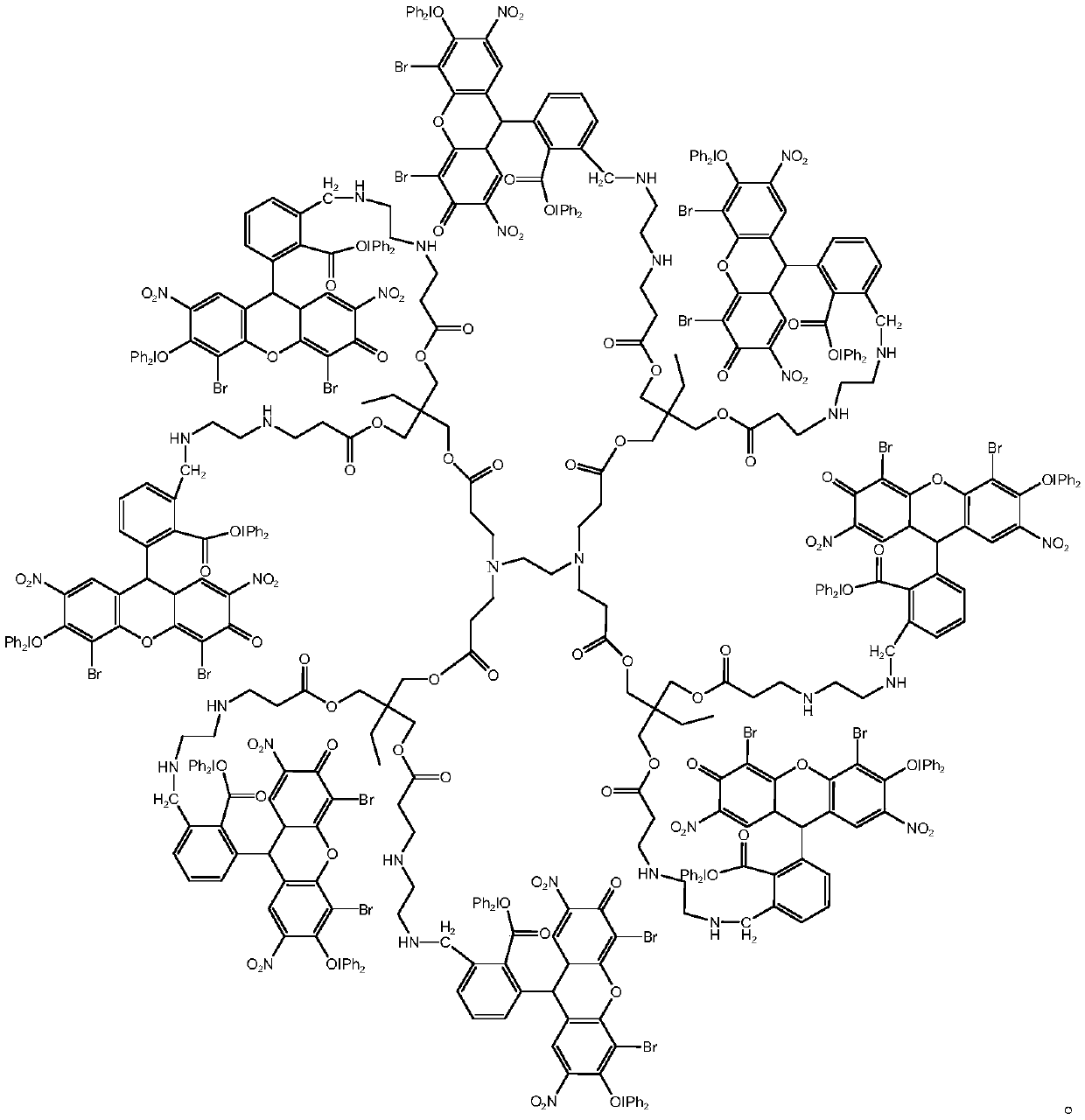

Dendritic eosin B-iodonium salt light initiator and preparation method and application thereof

A dendritic, visible light technology, applied in epoxy resin coatings, coatings, polyester coatings, etc., can solve the problems of high volatility, single function, weak anti-migration ability, etc., and achieve high initiation efficiency and strong penetration ability , the effect of cheap light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

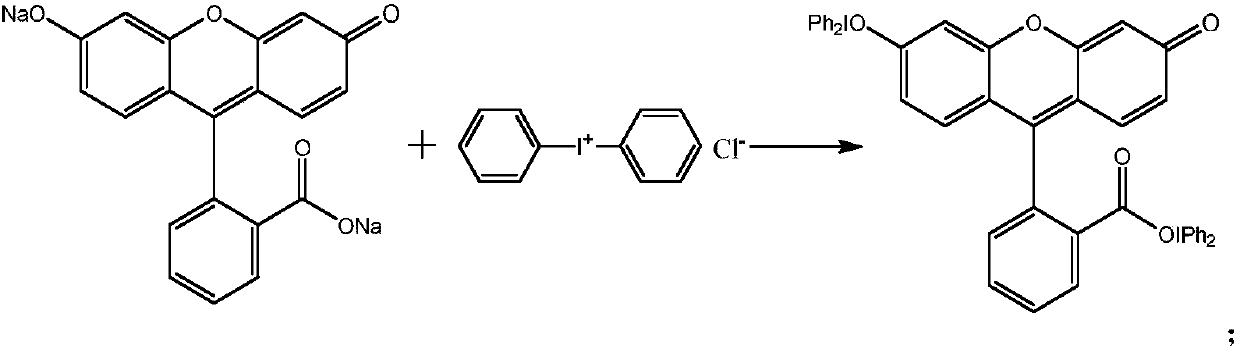

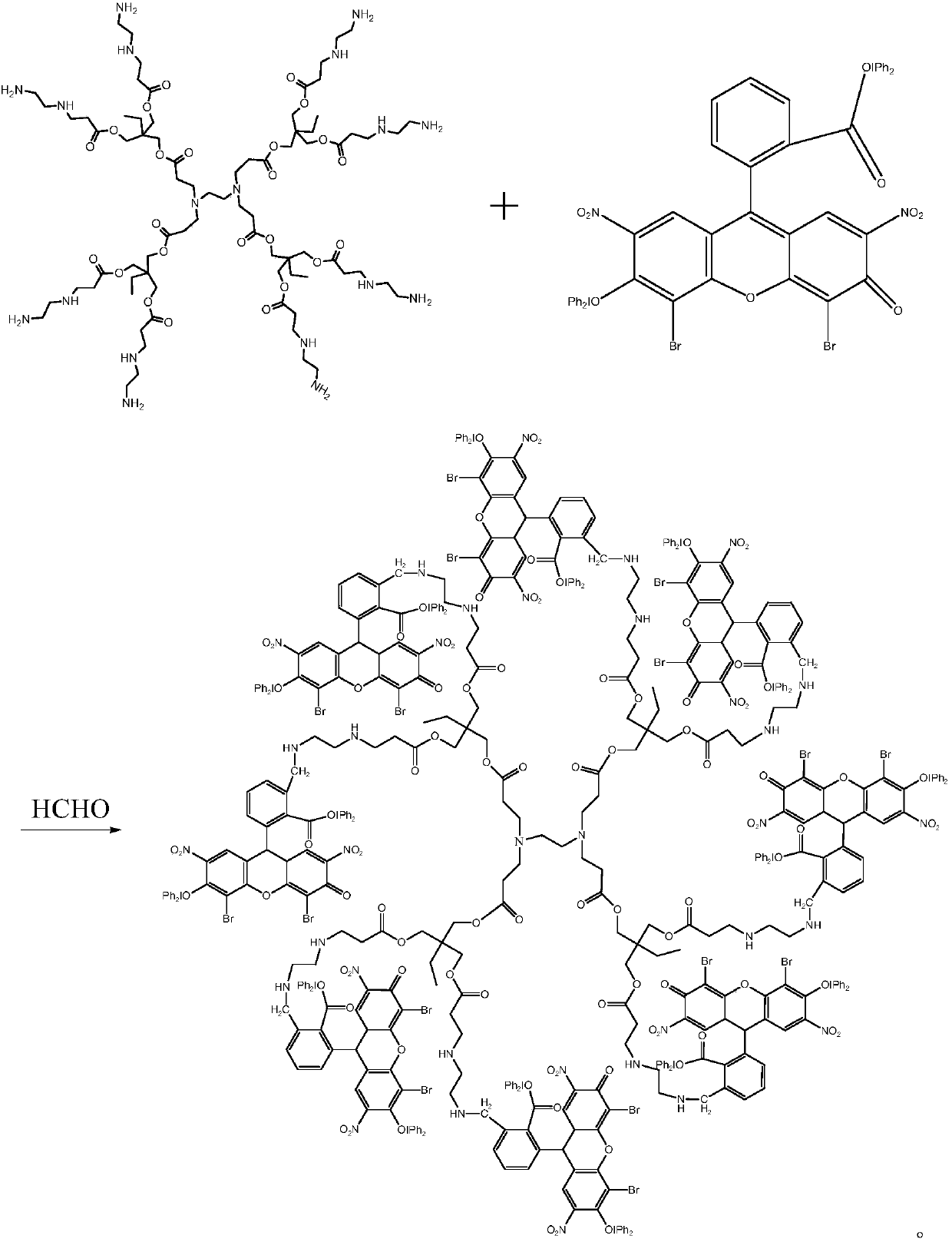

[0032] The preparation method of the dendritic eosin B-iodonium salt visible light initiator of above-mentioned structure, it comprises the steps:

[0033] (1) The end group of the intermediate is a dendrimer (PAE (=) of 8 acrylates 8 ) synthesis: mix trimethylolpropane triacrylate, ethylenediamine, and anhydrous methanol, heat to 30°C, react for 4-8 hours, wash with anhydrous methanol after the reaction, and obtain a colorless and transparent viscous liquid , the reaction formula is as follows:

[0034]

[0035] (2) Dendrimers with 8 primary amino groups at the end of the intermediate (PAE(NH 2 ) 8 ) synthesis: the PAE (=) 8 Mix with ethylenediamine, heat to 30°C, react for 24 hours, distill under reduced pressure, wash with ethyl acetate to obtain light yellow transparent viscous liquid, the reaction formula is as follows:

[0036]

[0037] (3) Synthesis of intermediate diphenyliodonium chloride: mix benzene, acetic anhydride, and potassium iodate, react in a brine...

Embodiment 1

[0044] Embodiment 1: the preparation of visible light initiator

[0045] (1) The synthesis of a dendrimer (PAE (=) 8) whose terminal group is 8 acrylates:

[0046] Mix 60g of trimethylolpropane triacrylate, 2.4g of ethylenediamine, and 30mL of anhydrous methanol, heat to 30°C, react for 6 hours, wash with anhydrous methanol, and obtain a colorless and transparent viscous liquid.

[0047] (2) Synthesis of a dendrimer (PAE(NH2) 8) with 8 primary amino groups at the end of the intermediate:

[0048] Mix 4.665g of PAE(=)8 and 108g of ethylenediamine, heat to 30-50°C, react for 24 hours, distill under reduced pressure, and wash with ethyl acetate to obtain a light yellow transparent viscous liquid.

[0049] (3) Synthesis of intermediate diphenyliodonium chloride salt:

[0050] Mix 9mL of benzene, 10mL of acetic anhydride, and 10.7g of potassium iodate, and slowly drop in a mixture of 7mL of concentrated sulfuric acid and 10mL of acetic anhydride in a brine ice bath (about -5°C). A...

Embodiment 2

[0057] Embodiment 2: PAE-EB (IPh 2 ) 2 Visible Light Initiated Unsaturated Resins

[0058] PAE-EB (IPh 2 ) 2 Visible Light Initiated Epoxy Acrylates:

[0059] Get 1.3g epoxy acrylate and 0.7g reactive diluent TMPTA, stir and mix, add the various visible photoinitiators (PAE-EB (IPh 2 ) 2 Photoinitiator, EB(IPh 2 ) 2 Photoinitiator and the combination photoinitiator (EB+10%Vc) that the co-initiator vitamin C of EB+10% by weight forms, mixes with the homogenizer, is coated with about 0.1mm thick film on glass sheet, places Curing under 500W LED lamp radiation, record the curing time. The results are shown in Table 1.

[0060] Table 1 Initiator triggers epoxy acrylate curing time

[0061]

[0062] PAE-EB (IPh 2 ) 2 Visible Light Initiated Hyperbranched Polyester Acrylates:

[0063] Get 1.3g hyperbranched polyester acrylate and 0.7g reactive diluent TMPTA, stir and mix, add the various visible photoinitiators (PAE-EB (IPh 2 ) 2 Photoinitiator, EB(IPh 2 ) 2 Phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com