Acrylic emulsion with self-wetting effect and emulsion type pressure-sensitive adhesive containing acrylic emulsion

An acrylic emulsion, self-wetting technology, applied in pressure-sensitive films/sheets, adhesives, adhesive types, etc., can solve the problems of high emulsion viscosity, easy to produce slag, large dosage, etc., to achieve good wetting performance, The effect of stable emulsion polymerization process and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

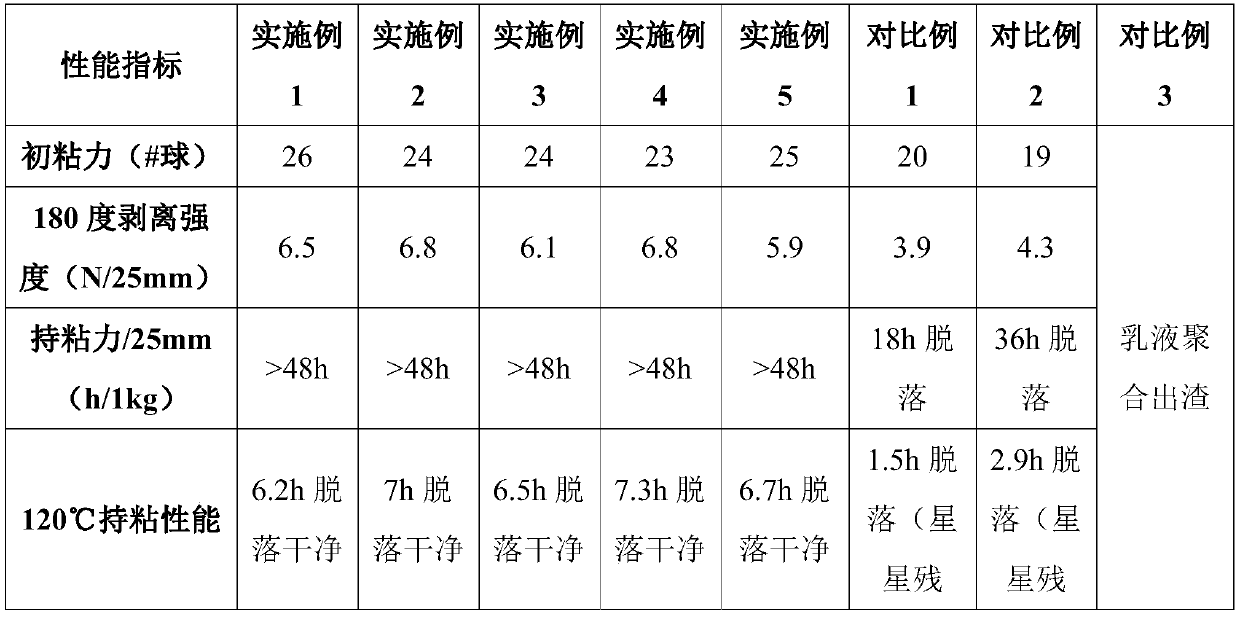

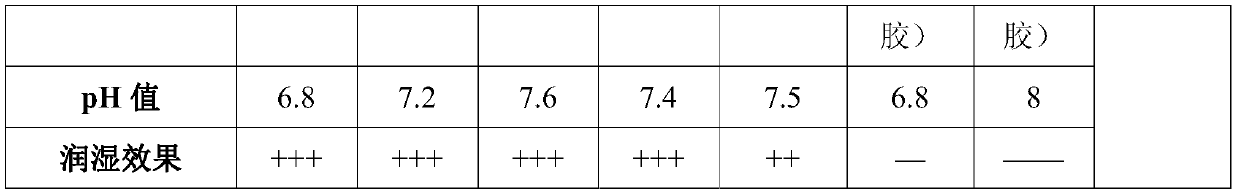

Examples

Embodiment 1

[0052] A kind of acrylic acid emulsion with self-wetting effect, its preparation method comprises the following steps:

[0053] 1) Stir and disperse 1.5g of allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate and 0.5g of ammonium persulfate with 50g of deionized water, then add 80g of butyl acrylate, 10g of methyl methacrylate, 3g Acrylic acid, 5g hydroxypropyl acrylate and 2g divinylbenzene, fully stirred and mixed to obtain a pre-emulsion;

[0054] 2) Stir and disperse 0.2 g of ammonium persulfate and 2 g of deionized water to obtain an initiator solution;

[0055] 3) Stir and disperse 0.3g sodium bicarbonate and 0.5g nonylphenol polyoxyethylene ether ammonium sulfate with 50g deionized water, then add 3.2g butyl acrylate, 0.4g methyl methacrylate, 0.12g acrylic acid, 0.2g Hydroxypropyl acrylate and 0.08g of divinylbenzene were fully stirred and mixed, and then heated to 80°C, and the initiator solution in step 2) was added, and after the blue light appeared, th...

Embodiment 2

[0060] A kind of acrylic acid emulsion with self-wetting effect, its preparation method comprises the following steps:

[0061] 1) Stir and disperse 2g of allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate and 0.5g of ammonium persulfate with 50g of deionized water, then add 75g of isooctyl acrylate, 19g of butyl methacrylate, 3g Methacrylic acid, 3g hydroxypropyl acrylate and 5g divinylbenzene, fully stirred and mixed to obtain a pre-emulsion;

[0062] 2) Stir and disperse 0.2 g of ammonium persulfate and 2 g of deionized water to obtain an initiator solution;

[0063] 3) Stir and disperse 0.23g sodium bicarbonate and 0.5g sodium dodecyl diphenyl ether disulfonate with 45g deionized water, then add 3.75g isooctyl acrylate, 0.95g butyl methacrylate, 0.15g formazan Acrylic acid, 0.15g hydroxypropyl acrylate and 0.25g divinylbenzene, fully stirred and mixed, then heated to 80 ° C, added the initiator solution of step 2), and kept warm for 30 minutes after the blue ...

Embodiment 3

[0068] A kind of acrylic acid emulsion with self-wetting effect, its preparation method comprises the following steps:

[0069] 1) Stir and disperse 2.5g of allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate and 0.4g of ammonium persulfate with 50g of deionized water, then add 90g of isooctyl acrylate, 5g of styrene, and 2g of acrylamide , 2g hydroxyethyl methacrylate and 2g diacetone acrylamide, fully stirred and mixed to obtain a pre-emulsion;

[0070] 2) Stir and disperse 0.2 g of ammonium persulfate and 2 g of deionized water to obtain an initiator solution;

[0071] 3) Stir and disperse 0.23g sodium bicarbonate and 0.5g sodium dodecyl diphenyl ether disulfonate with 50g deionized water, then add 5.4g isooctyl acrylate, 0.3g styrene, 0.12g acrylamide, 0.12 1 g of hydroxyethyl methacrylate and 0.12 g of diacetone acrylamide, fully stirred and mixed, then heated up to 80°C, added the initiator solution in step 2), and kept warm for 30 minutes after the blue lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com