A kind of guanidinoluteolin-chromium (iii) complex and preparation method thereof

A technology of luteolin and complexes, applied in the field of biomedicine, can solve problems such as toxicity reduction and heavy metal poisoning, and achieve the effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

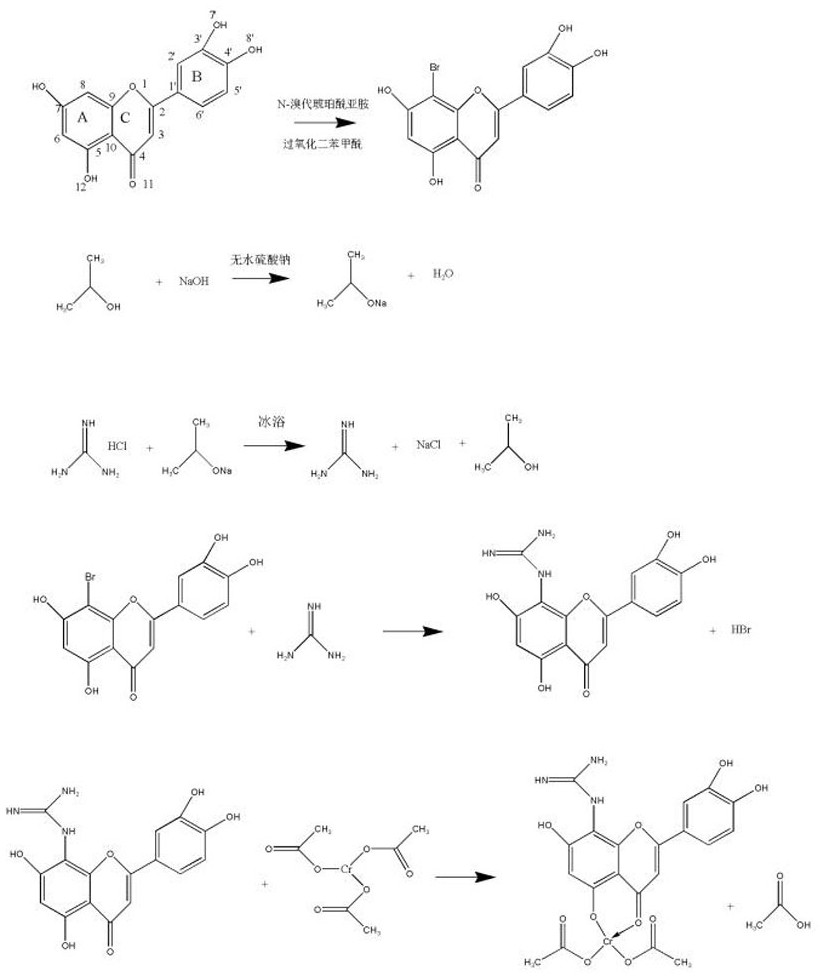

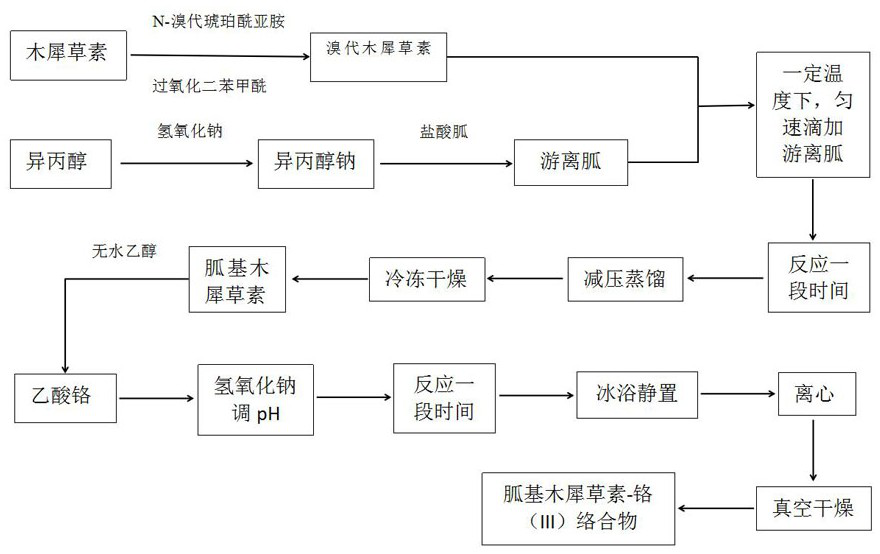

[0032] Preparation of Guanidinoluteolin-Chromium(III) Complex:

[0033] Step a: Dissolve NBS in acetone and stir at room temperature, avoid light, dissolve as much as possible, pour into the dropping funnel for dropwise addition, dissolve luteolin in acetone, add BPO, put the dropping funnel under ice bath Start to add slowly, and after the dropwise addition, heat to 80°C and react for 18 hours. After the reaction, carry out vacuum distillation to remove acetone, wash with deionized water several times, and freeze-dry to obtain bromoluteolin, wherein n(luteolin):n(NBS)=1:1.5, m(BPO):m(luteolin)=5%;

[0034] Step b: Add solid sodium hydroxide to isopropanol at room temperature, stir with a glass rod, remove water with anhydrous sodium sulfate, and dissolve sodium hydroxide in isopropanol as much as possible, where n (sodium hydroxide) :n(isopropanol)=1:30;

[0035] Step c: under ice bath conditions, sodium isopropoxide is added to the container, guanidine hydrochloride is add...

Embodiment 2

[0039] Preparation of Guanidinoluteolin-Chromium(III) Complex:

[0040] Step a: Dissolve NBS in acetone and stir at room temperature, avoid light, dissolve as much as possible, pour into the dropping funnel for dropwise addition, dissolve luteolin in acetone, add BPO, put the dropping funnel under ice bath Start to add slowly, and after the dropwise addition, heat to 70°C and react for 12 hours. After the reaction, carry out vacuum distillation to remove acetone, wash with deionized water several times and then freeze-dry to obtain bromoluteolin, wherein n(luteolin):n(NBS)=1:1.1, m(BPO):m(luteolin)=4%;

[0041] Step b: Add solid sodium hydroxide to isopropanol at room temperature, stir with a glass rod, remove water with anhydrous sodium sulfate, and dissolve sodium hydroxide in isopropanol as much as possible, where n (sodium hydroxide) :n(isopropanol)=1:25;

[0042] Step c: under ice bath conditions, sodium isopropoxide is added to the container, guanidine hydrochloride is a...

Embodiment 3

[0050] Preparation of Guanidinoluteolin-Chromium(III) Complex:

[0051] Step a: Dissolve NBS in acetone and stir at room temperature, avoid light, dissolve as much as possible, pour into the dropping funnel for dropwise addition, dissolve luteolin in acetone, add BPO, put the dropping funnel under ice bath Start to add slowly, and after the dropwise addition, heat to 50°C and react for 9 hours. After the reaction, carry out vacuum distillation to remove acetone, wash with deionized water several times and freeze-dry to obtain bromoluteolin, wherein n(luteolin):n(NBS)=1:1.3, m(BPO):m(luteolin)=3%;

[0052] Step b: Add solid sodium hydroxide to isopropanol at room temperature, stir with a glass rod, remove water with anhydrous sodium sulfate, and dissolve sodium hydroxide in isopropanol as much as possible, where n (sodium hydroxide) :n(isopropanol)=1:25;

[0053] Step c: under ice bath conditions, sodium isopropoxide is added to the container, guanidine hydrochloride is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com