Surface modification method for titanium carbide particles

A surface modification and particle surface technology, applied in the field of materials, can solve the problems such as the surface composition and morphology of the reconstructed particles that are not involved in the surface modification of titanium carbide particles, and achieve good ion diffusion conditions for reactants, smooth surfaces, and spherical coefficients. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

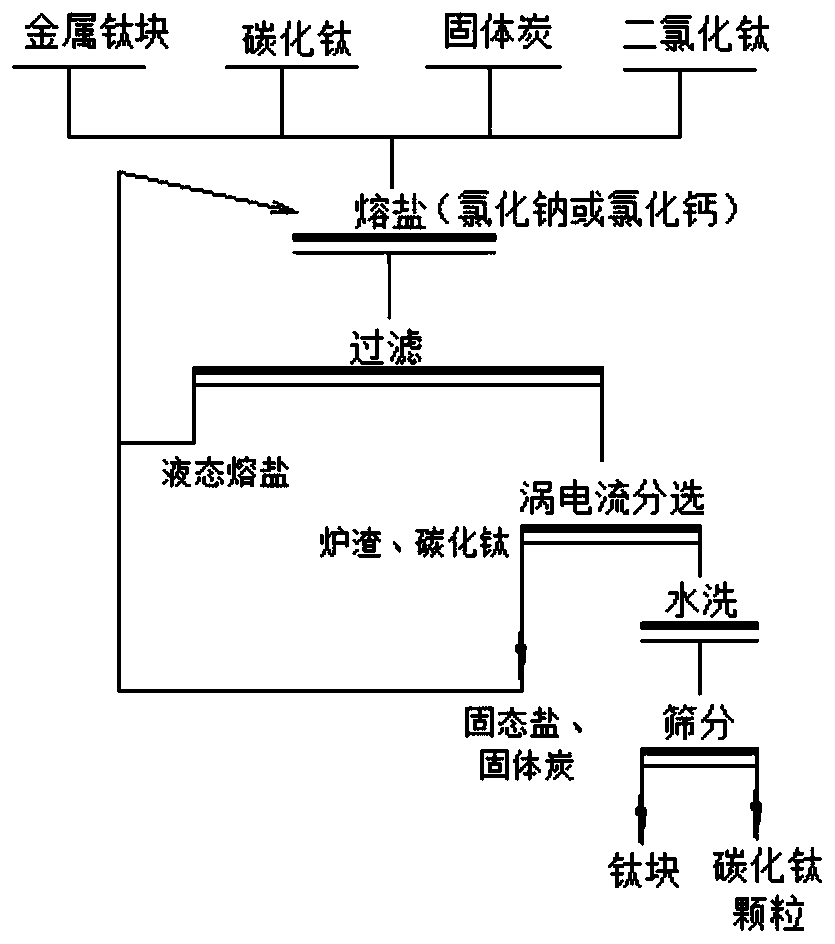

example 1

[0028] The spherical coefficient of a commercial titanium carbide particle is about 67%. With sodium chloride as molten salt, (m Ti +m TiC +m TC +m c ):m s =1:2.4. Among them, m Ti 、m TiC 、m TC 、m c 、m s are the mass of metallic titanium, titanium carbide, titanium dichloride, solid carbon and molten salt in the molten salt, respectively. The temperature rise rate from room temperature to 575°C is between 5.51°C / min and 5.56°C / min, the temperature rise rate between 575°C and 998°C is between 3.96°C / min and 3.99°C / min, and the temperature rise rate between 999°C and 1198°C The heating rate between ℃ is between 2.88℃ / min and 2.91℃ / min; after the temperature reaches the predetermined temperature, it is kept at 1191℃-1198℃ for 3 hours. Use a porous plate at high temperature to filter out most of the liquid molten salt from the solid product; after the molten salt is cooled, remove the solid product and add water to adjust the slurry concentration to 51% to 52%, and use ...

example 2

[0030] The spherical coefficient of a commercial titanium carbide particle is about 71%, and the particle size is uneven. With calcium chloride as molten salt, (m Ti +m TiC +m TC +m c ):m s =1:2.9. Among them, m Ti 、m TiC 、m TC 、m c 、m s are the mass of metallic titanium, titanium carbide, titanium dichloride, solid carbon and molten salt in the molten salt, respectively. The temperature rise rate from room temperature to 575°C is between 5.51°C / min and 5.56°C / min, the temperature rise rate between 575°C and 998°C is between 3.96°C / min and 3.99°C / min, and the temperature rise rate between 999°C and 1198°C The heating rate between ℃ is between 2.88℃ / min and 2.91℃ / min, and after reaching the predetermined temperature, it is kept at 1161℃-1168℃ for 5 hours. Use a porous plate at high temperature to filter out most of the liquid molten salt from the solid product; after the molten salt is cooled, remove the solid product and add water to adjust the slurry concentration ...

example 3

[0032] The spherical coefficient of a commercial titanium carbide particle is about 82%, and the particle size is uneven. With calcium chloride as molten salt, (m Ti +m TiC +m TC +m c ):m s =1:3.5. Among them, m Ti 、m TiC 、m TC 、m c 、m s are the mass of metallic titanium, titanium carbide, titanium dichloride, solid carbon and molten salt in the molten salt, respectively. The temperature rise rate from room temperature to 575°C is between 5.22°C / min and 5.23°C / min, the temperature rise rate between 575°C and 998°C is between 3.83°C / min and 3.84°C / min, and the temperature rise rate between 999°C and 1198°C The heating rate between °C is between 2.66 °C / min and 2.68 °C / min, and after reaching the predetermined temperature, keep it at 1196 °C-1197 °C for 4 hours. Use a porous plate at high temperature to filter out most of the liquid molten salt from the solid product; after the molten salt is cooled, remove the solid product and add water to adjust the slurry concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com