Organic photo-thermoelectric composite material, preparation method and application thereof, photo-thermoelectric battery and optical delay control system

A composite material and photothermoelectric technology, which is applied in the fields of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, photovoltaic power generation, etc. and thermoelectric conversion performance, the effect of improving capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

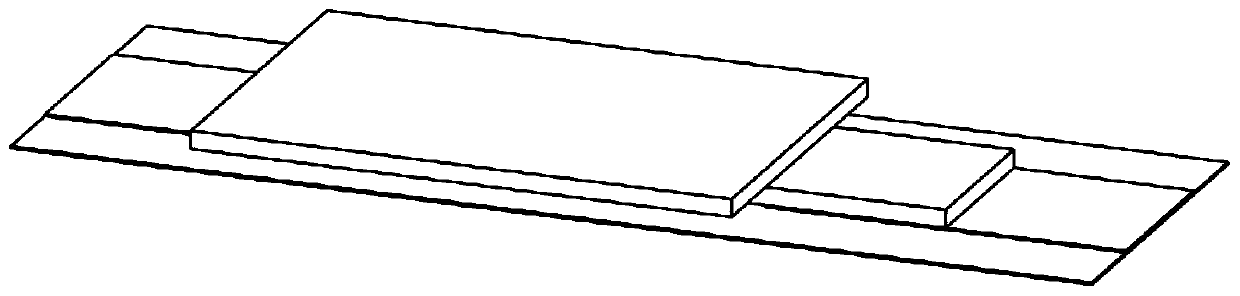

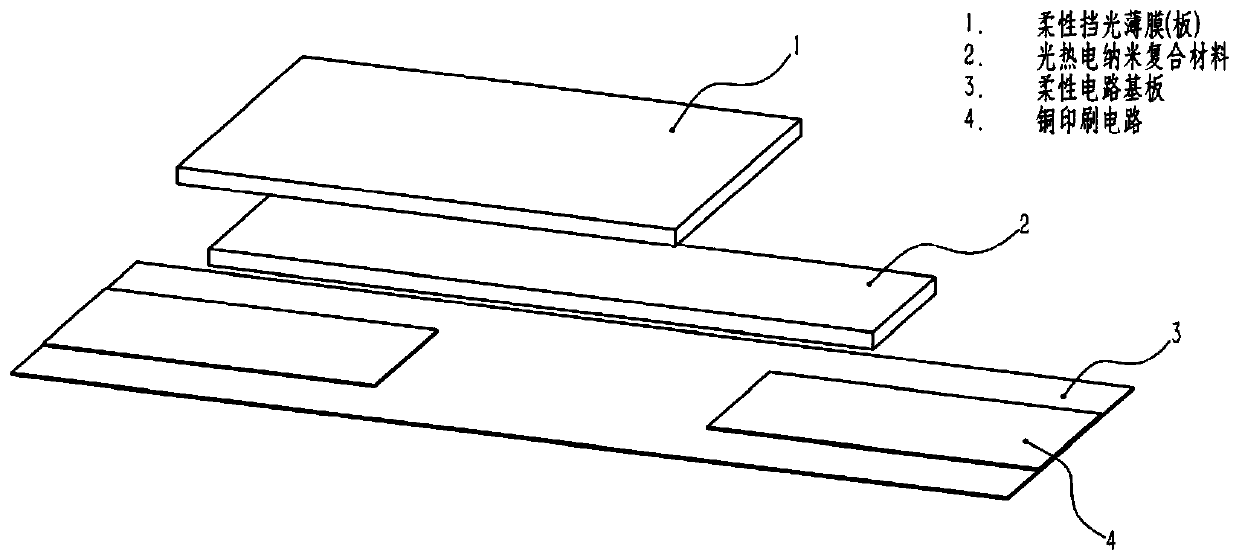

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing an organic photothermoelectric composite material, comprising the following steps:

[0031] S1, preparation of reaction mixture

[0032] The carbon nanotubes, dopant solution and polymerized monomers are mixed to form a reaction mixture. Before the initiator is mixed, other components are mixed, so that the polymerized monomers are supported on the carbon nanotubes, and the dopant can be doped in the organic polymer during the polymerization process.

[0033] Specifically, the organic polymer is selected from any one or more of polypyrrole and its derivatives, polythiophene and its derivatives, polyaniline and its derivatives, and polyacetylene; that is, the polymerization monomer is pyrrole, Any one or more of thiophene, aniline and acetylene. The dopant is selected from p-toluenesulfonic acid, sodium p-toluenesulfonate, p-hydroxybenzenesulfonic acid, dodecylbenzenesulfonic acid, sodium dodecylbenzenesulfonate, β-naphthal...

Embodiment 1

[0056] This embodiment provides a method for preparing an organic photothermoelectric composite material, which includes the following steps:

[0057] Helical carbon nanotubes (HCNTs) were added to 0.2mol / L sodium dodecylbenzenesulfonate (SDBS) solution, stirred and dispersed for 30min, and treated in a 100W cell disruptor for 1h. Then add pyrrole monomer and mix evenly, place in a 0 degree water bath, stir and pre-cool for 1 hour.

[0058] Add ferric chloride solution to the pre-cooled reaction mixture to initiate polymerization, the polymerization temperature is 0 degrees Celsius, and the polymerization time is 8 hours. The obtained product was washed with deionized water and absolute ethanol, and freeze-dried at -50°C for 48 hours to obtain a composite material. Wherein, the molar ratio of polymer monomer, dopant and initiator is 1:0.1:1.5; the mass ratio of carbon nanotubes and polymer monomer is 1:30.

[0059] The prepared composite material was cold-pressed at 10 MPa i...

Embodiment 2

[0061] This embodiment provides a method for preparing an organic photothermoelectric composite material, which includes the following steps:

[0062] Helical carbon nanotubes (HCNTs) were added to 0.2 mol / L p-toluenesulfonic acid solution, stirred and dispersed for 30 min, and treated in a 100W cell disruptor for 0.5 h. Then add pyrrole monomer and mix evenly, place in 4°C water bath and stir for pre-cooling for 2 hours.

[0063] Sodium dichromate solution was added to the pre-cooled reaction mixture to initiate polymerization, the polymerization temperature was 4 degrees Celsius, and the polymerization time was 5 hours. The obtained product was washed with deionized water and absolute ethanol, and freeze-dried at -40°C for 72 hours to obtain a composite material. Wherein, the molar ratio of polymer monomer, dopant and initiator is 1:0.2:1.8; the mass ratio of carbon nanotubes and polymer monomer is 1:50.

[0064] The prepared composite material was cold-pressed at 8MPa in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com