Environment-friendly high-barrier packaging paper and preparation method thereof

A high-barrier, wrapping paper technology, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of non-degradation and poor bacteriostatic performance, and achieve the effects of easy degradation, improved hydrophobicity, and improved barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of this wrapping paper comprises the steps:

[0045] Coating: Coating the coating liquid evenly on the surface of the base paper, using single-sided coating, the coating amount is 6g / m 2 ;

[0046] Drying: Put the coated coated paper into a drying oven at 68°C immediately for drying, and take it out after 160-170s;

[0047] Constant temperature and humidity treatment: place the dried coated paper in a constant temperature and humidity box for rehumidification treatment. The treatment conditions are set as follows: the temperature is 23-24 °C, the relative humidity is 50%, and the time is 46-48 hours. wrapping paper.

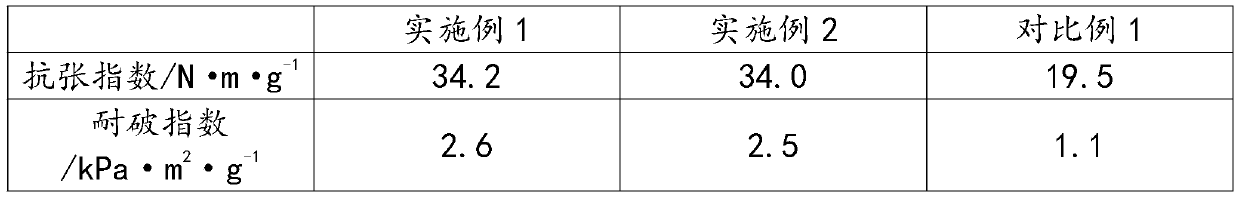

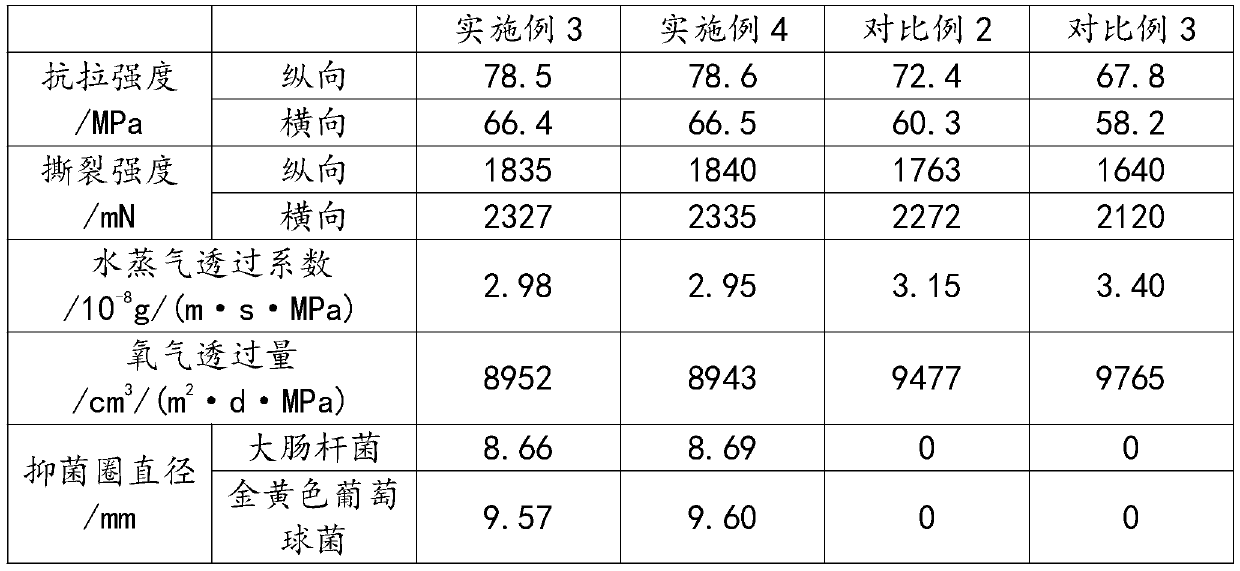

Embodiment 1

[0049] The base paper is prepared by the following method:

[0050] (1) Soak the mucormycetes in 0.4mol / L NaOH solution for 15 days, during which the lye is replaced 3 times until the mycelium becomes milky white, and the immersion can be ended when the lye no longer changes color, and the mucormycete fiber is obtained;

[0051] (2) Wash the soaked mucormycetes fiber with deionized water to neutrality, and use a high-speed dispersion homogenizer to homogenize for 30 minutes at 20000r / min to obtain a milky mycelium liquid;

[0052] (3) Tear the bleached coniferous wood pulp board into small pieces and soak it in water for 4-5 hours, then disintegrate, beat, and dehydrate (wherein, the degree of beating is 17.5°SR), and mix the milky mycelium liquid with the dehydrated softwood pulp Mixed flakes (the mass ratio of milky mycelium liquid to dehydrated softwood pulp is 1:4.3), quantitative 60g / m 2 , wet paper sheets at 2.8 x 10 4 Squeeze for 5 minutes under Pa pressure, and dry e...

Embodiment 2

[0054] The base paper is prepared by the following method:

[0055] (1) Soak mucormycetes in 0.4mol / L NaOH solution for 18 days, during which the lye is replaced 4 times until the mycelium becomes milky white, and the immersion can be ended when the lye no longer changes color, and the mucormycete fiber is obtained;

[0056] (2) Wash the soaked mucormycetes fiber with deionized water to neutrality, and use a high-speed dispersion homogenizer to homogenize for 40 minutes at 20000r / min to obtain a milky mycelium liquid;

[0057] (3) Tear the bleached coniferous wood pulp board into small pieces and soak it in water for 5 hours, then perform thawing, beating, and dehydration (wherein, the beating degree is 17.5°SR), and mix the milky mycelium liquid with the dehydrated coniferous wood pulp. Sheets (the mass ratio of milky mycelium liquid to dehydrated softwood pulp is 1:4.5), quantitative 60-66g / m 2 , wet paper sheets at 2.8 x 10 4 Squeeze for 5 minutes under Pa pressure, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com