FeCo@MXene core-shell structure composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material, core-shell structure technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limited absorbing performance of MXene, magnetic loss mechanism introduced by MXene, etc., and achieve broadband strong electromagnetic wave absorption characteristics , Significant dielectric polarization loss characteristics, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

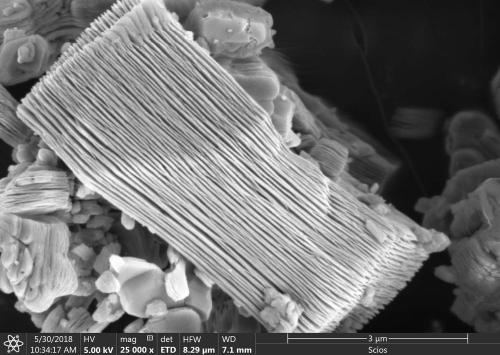

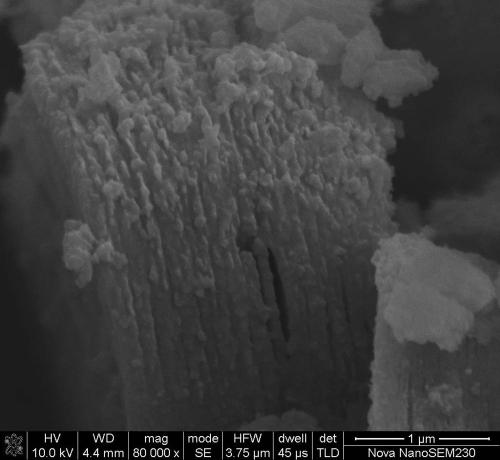

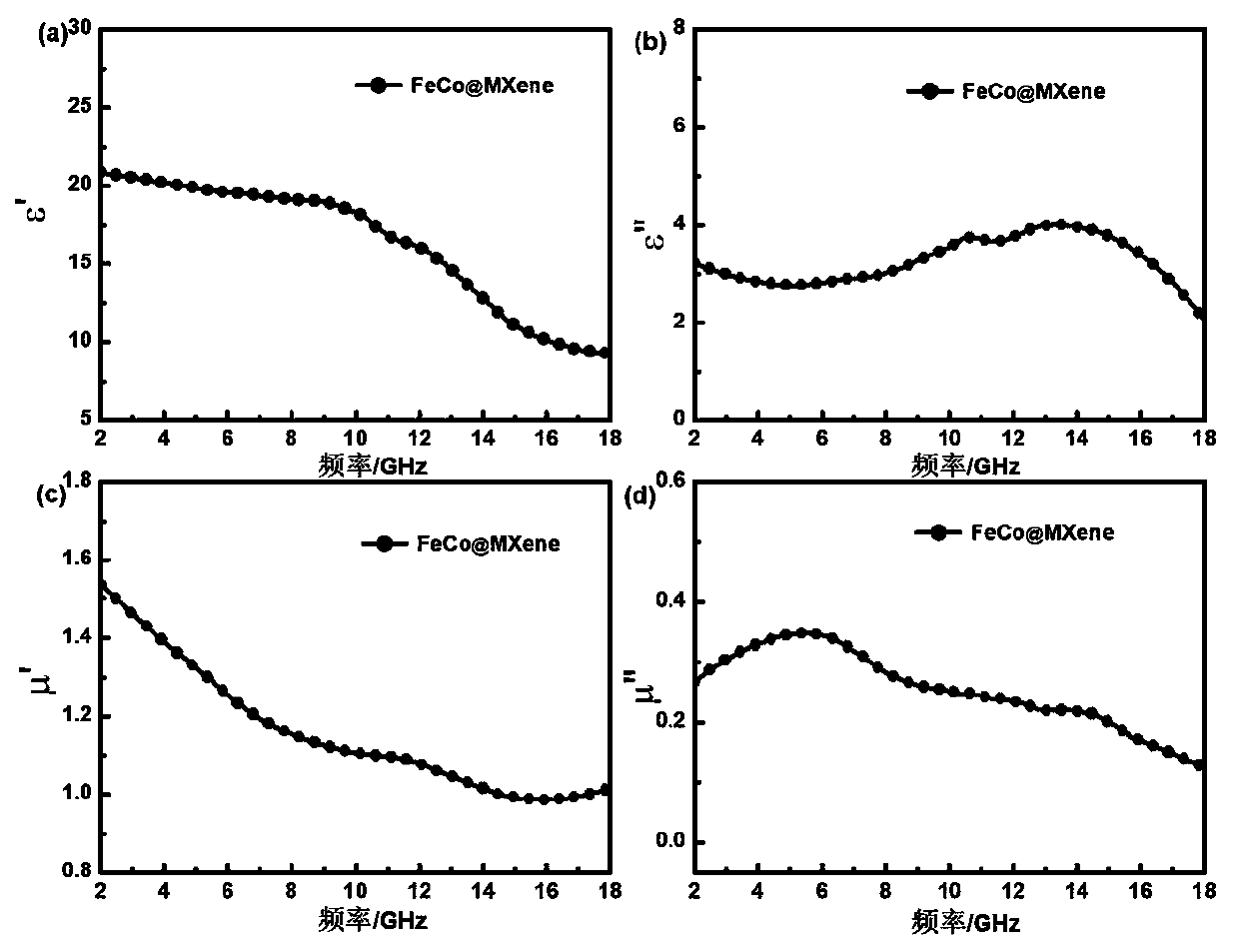

[0029] (1) Weigh 5gTi 3 SiC 2 The MAX phase powder was poured into a 500 mL polytetrafluoroethylene beaker filled with a 40% hydrofluoric acid solution, and stirred magnetically at a speed of 300 r / min for 24 h under the assistance of an ultrasonic power of 40 W; After the reaction was completed, the above mixed solution was left to stand for 2 hours and then the supernatant was removed, then the black precipitate was washed with deionized water for 3 times, then filtered and dried at 80°C for 2 hours to obtain MXene powder. The microscopic appearance of the tested powder was as follows: figure 1 As shown, it can be seen that the MXene prepared in the present invention presents a lamellar microstructure with uniform morphology.

[0030] (2) Weigh 2.3g CoCl respectively 2 •6H 2 O and 2.8 g FeSO 4 ·7H 2 O, and dissolved in a glass flask equipped with 150 mL of ethylene glycol solvent; add the lamellar MXene powder obt...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] (1) Weigh 6gTi 3 AlC 2 The MAX phase powder was poured into a 500 mL polytetrafluoroethylene beaker filled with a 40% hydrofluoric acid solution, and stirred magnetically at a speed of 300 r / min for 12 h under the assisted action of ultrasound with a power of 60 W; After the reaction, the above mixture was left to stand for 2 hours and the supernatant was removed, then the black precipitate was washed 4 times with deionized water, then filtered and dried at 60°C for 2 hours to obtain a lamellar MXene powder;

[0036] (2) Weigh 4.5g CoSO 4 •6H 2 O and 5.5 g FeSO 4 ·7H 2O, and be dissolved in the glass flask that 150 mL ethanol solvent is housed, add the lamellar MXene powder that step (1) obtains, and with 250 r / min rotating speed magnetic stirring is uniformly dispersed 3h to form mixed solution; Add 20mL of 80% hydrazine hydrate solution and NaOH compound, adjust its pH to 13, and continue to disperse with m...

Embodiment 3

[0038] This embodiment includes the following steps:

[0039] (1) Weigh 8gTi 3 SiC 2 The MAX phase powder was poured into a 500 mL polytetrafluoroethylene beaker filled with a 40% hydrofluoric acid solution, and stirred magnetically at a speed of 400 r / min for 18 h under the assistance of an ultrasonic power of 80 W; After the reaction was completed, the above mixture was left to stand for 3 h and then the supernatant was removed, then the black precipitate was washed 5 times with deionized water, filtered and dried at 60 °C for 3 h to obtain MXene powder.

[0040] (2) Weigh 11.2g Co(NO 3 ) 2 •6H 2 O and 10.8 g FeSO 4 ·7H 2 O, and be dissolved in the glass flask that 150 mL ethylene glycol solvent is housed, add the lamellar MXene powder that step (1) obtains, and with 400 r / min rotating speed magnetic stirring the mixed solution that disperses 2h evenly; Add mixed solution Slowly add 25mL of 80% hydrazine hydrate solution and NaOH compound to adjust the pH to 12, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com