Wear-resisting lining plate

A wear-resistant liner and liner technology, which is applied in the field of metal materials, can solve the problems of high alloy content and increased cost, and achieve the effects of reducing cost, improving utilization rate and crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The applicant explains the structure and embodiment of the corrosion-resistant and wear-resistant liner with reference to the accompanying drawings.

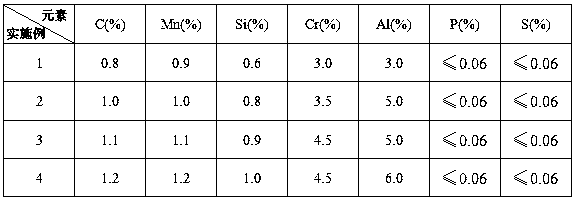

[0036] In the alloy, adding tungsten and a small amount of rhenium will increase the red hardness of the product, and the mill has high requirements on the red hardness of the product, so tungsten and a small amount of rhenium are added to the bottom plate of the mill Adding aluminum elements will increase the plasticity of the product, so the addition of aluminum elements to the bottom plate of the crusher increases the plasticity of the product and prevents the liner from cracking. The carbon content also affects the hardness and brittleness of the product.

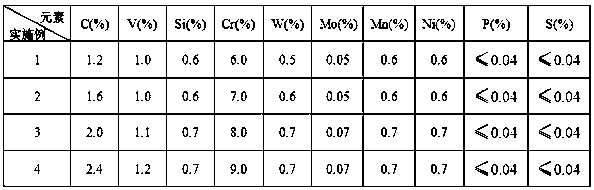

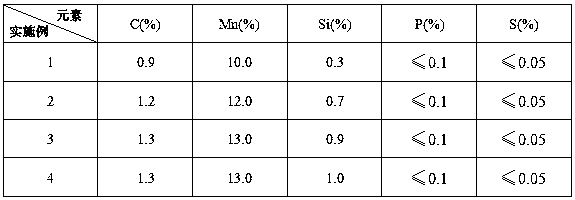

[0037] From attached figure 1 to attach Figure 4 Respectively represent the element mass percentage content of high chromium steel, high manganese steel, crusher bottom plate and mill bottom plate. It should be pointed out that the chromium content of general sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com