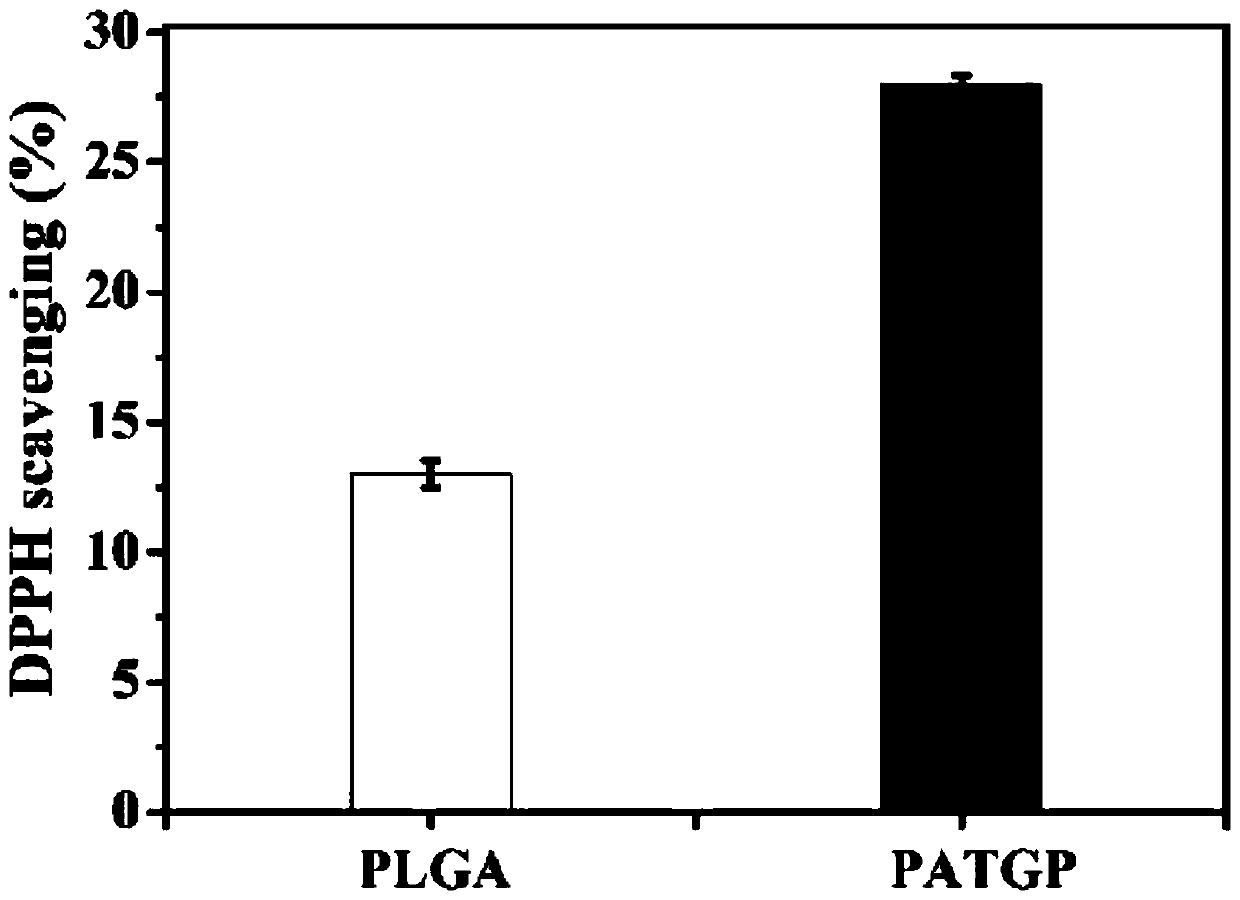

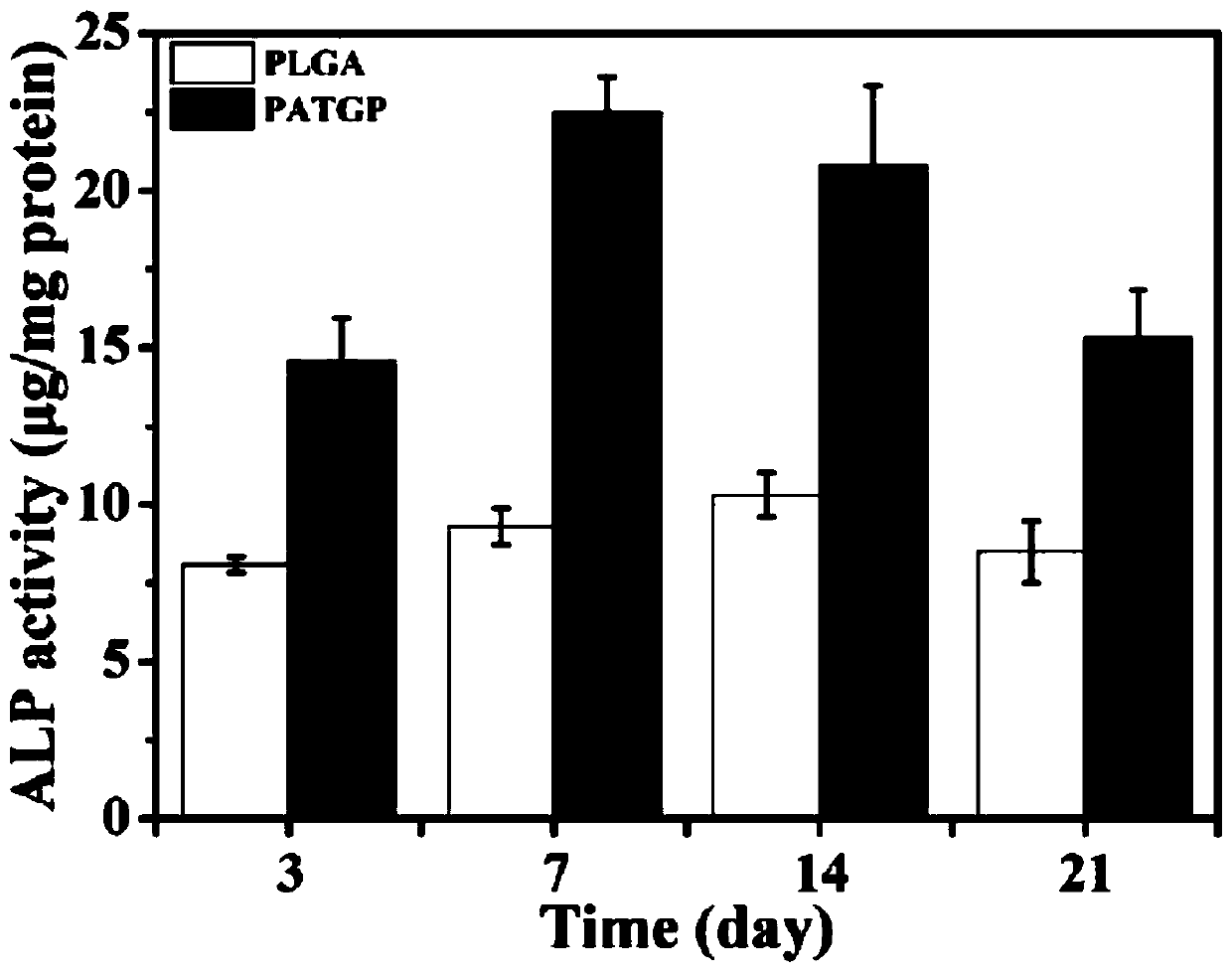

Multifunctional polyphosphazene bone repair material with anti-oxidation and osteogenesis promoting capability and preparation method of multifunctional polyphosphazene bone repair material

A technology of osteogenic ability and polyphosphazene, which is applied in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of ROS enrichment, adverse effects of tissue regeneration, single form and function, etc., and achieves easy regulation of performance and molecular structure. Designable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] (1) Preparation and purification of linear polydichlorophosphazene: put the purified hexachlorocyclotriphosphazene into the polymerization tube, vacuumize the oxygen and water removal and seal the tube under vacuum, then place the polymerization tube at 250°C Polymerize at low temperature for 24-60 hours, then break the polymerization tube to take out the polymer, add dry petroleum ether to wash three times to remove unreacted monomers, and obtain linear polydichlorophosphazene.

[0026] (2) Preparation of amino acid ester solution: Dissolve amino acid ester hydrochloride and acid-binding agent in dry tetrahydrofuran (200mL) according to the amount of substances 1:2, reflux for 6-48 hours, and filter to remove the generated acid-binding agent hydrochloric acid salt to obtain a tetrahydrofuran solution of amino acid esters.

[0027] (3) Nucleophilic substitution of linear polydichlorophosphazene: dissolve polydichlorophosphazene in dry tetrahydrofuran (100mL) 2 - The mola...

Embodiment 1

[0031] Put the purified hexachlorocyclotriphosphazene (30g) into the polymerization tube, vacuumize (10mbar), fill with dry nitrogen, repeat three times to remove oxygen and water from the system, seal the tube under vacuum, and then place it at 250°C Polymerization was carried out for 48 hours. After the polymerization reaction, break the polymerization tube to take out the polymer, add dry petroleum ether to wash three times to remove unreacted monomers, and obtain linear polydichlorophosphazene.

Embodiment 2

[0033] Polydichlorophosphazene (containing 8.62mmol-PNCl 2 -Structural unit) was dissolved in 100mL of dry tetrahydrofuran, 1.73mmol of aniline tetramer and 1.73mmol of triethylamine were added, and reacted at 50°C for 24 hours under anhydrous and oxygen-free conditions, and then added with 18.64mmol of glycine ethyl ester salt acid salt and 37.28mmol triethylamine reflux reaction for 6 hours of tetrahydrofuran solution (200mL), continue to react at 35 ℃ for 24 hours, to obtain poly (aniline tetramer / ethyl glycine) phosphazene, wherein, the substitution of aniline tetramer The ratio was ~10 mol%, and the substitution ratio of glycine ethyl ester was ~90 mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com