Selenium-rich Hakka wine cooking

A Hakka, selenium-enriched technology, applied in the preparation of alcoholic beverages, plant raw materials, urinary system diseases, etc., can solve problems such as lack of cooperation, and achieve the effects of avoiding waste, eliminating fatigue, and enhancing immunity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

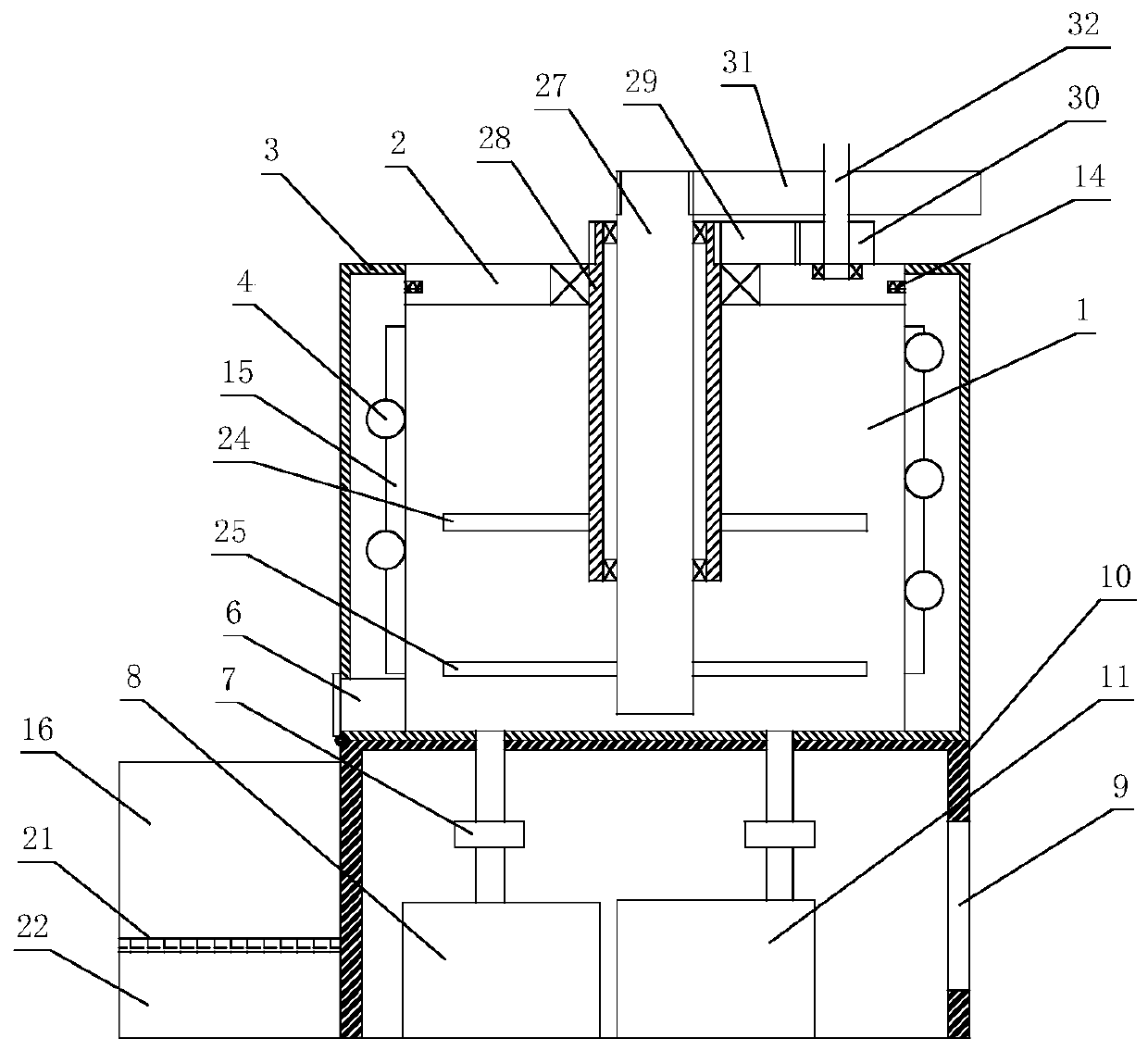

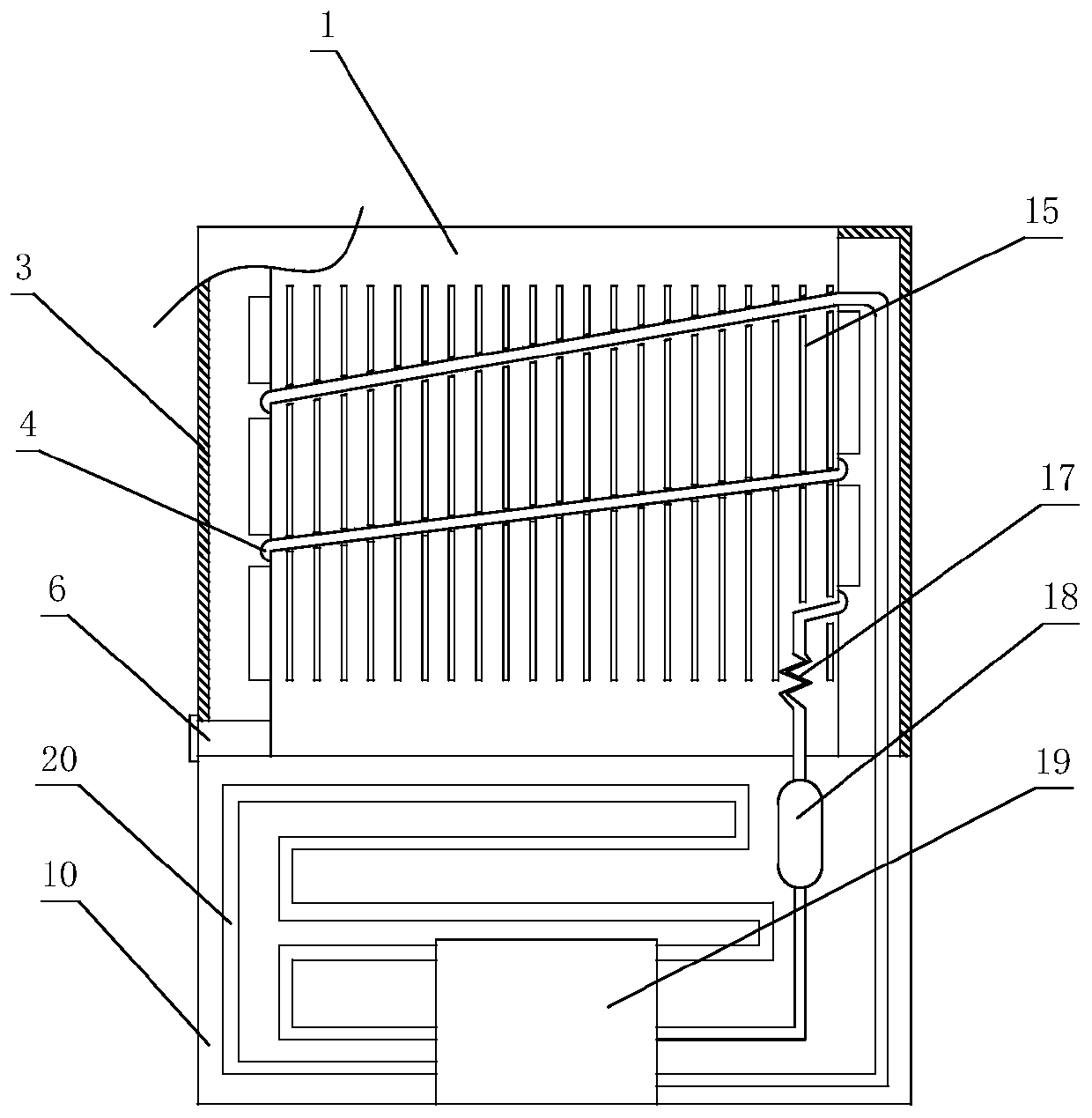

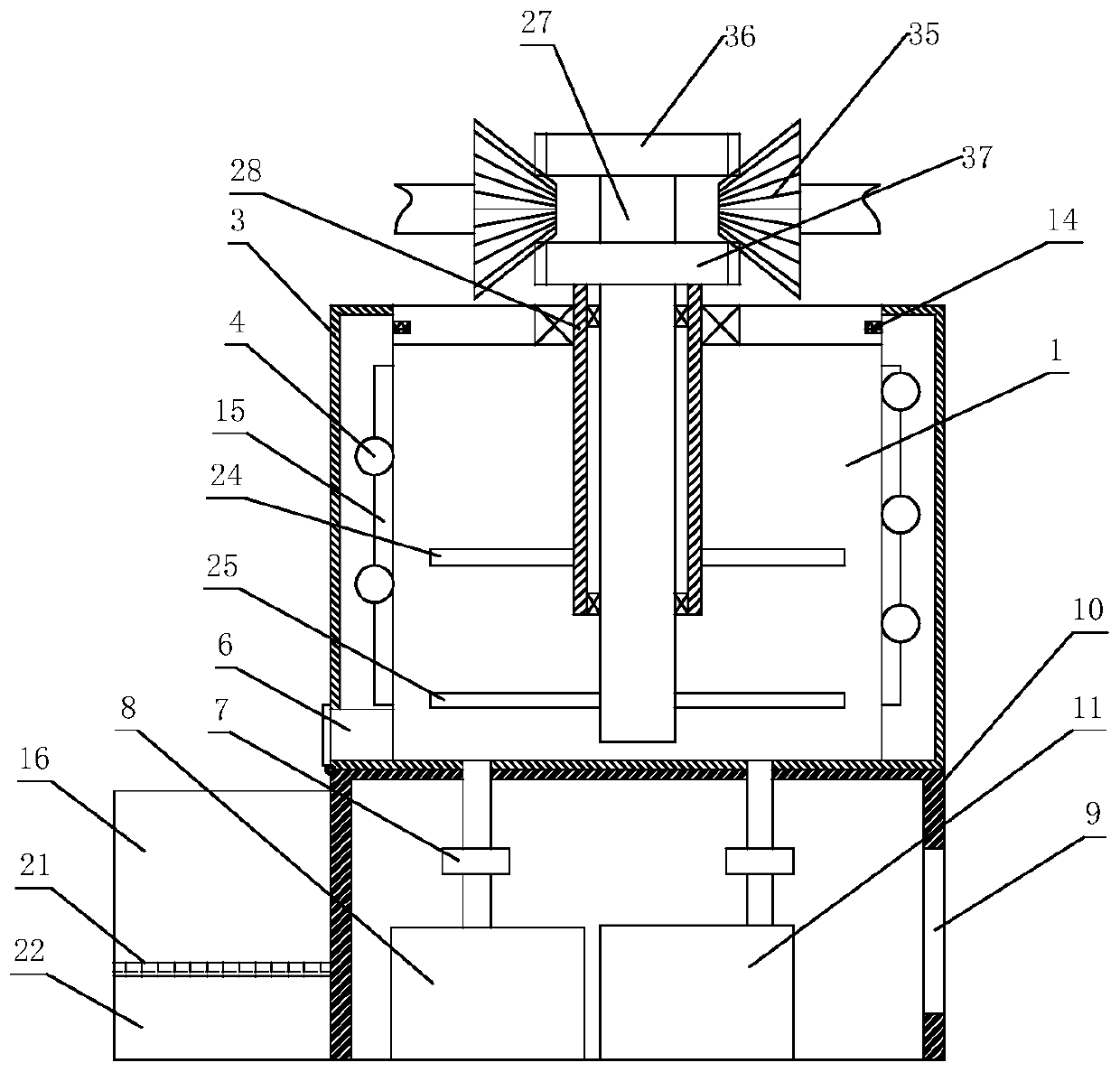

Image

Examples

Embodiment 1

[0042] The selenium-enriched Hakka boiled wine of the present invention, the processing steps include:

[0043] Select selenium-enriched glutinous rice to brew Hakka rice wine according to the Hakka brewing method. The specific steps are:

[0044] Rice selection: select high-quality dry selenium-enriched glutinous rice to remove impurities;

[0045] Rice soaking: Put the selected rice into the tank and soak it in clear water to ensure that the rice grains have no hard core. The rice soaking time is 2.5 hours;

[0046] Steam rice: Steam rice with a rice steamer, put the soaked rice into the rice steamer after the water boils, and control the steaming time to 25 minutes;

[0047] Mixing koji: Put the steamed rice on a flat plate to cool, and add rice wine koji when the temperature reaches 28°C;

[0048] Saccharification and fermentation: Put the rice mixed with koji into a clean and sterilized pottery vat, make a nest in the middle of the vat, increase the contact area between t...

Embodiment 2

[0056] The mulberry in the material bag in embodiment 1 is the mulberry superfine powder that is processed into by cell crushing, freeze-drying and superfine pulverization with fresh mulberries.

Embodiment 3

[0058] The specific processing steps of the mulberry superfine powder used in the embodiment two are as follows:

[0059] 1) Put the mulberry raw material in an airtight container and keep it under a positive pressure of 0.3MPa for 6min, vacuumize the container where the mulberry raw material is located to form a vacuum of 0.5MPa, then place it for 30min, repeat 5 cycles, and complete the mulberry material Naturally break at room temperature and become a paste;

[0060] 2) Add pectinase EX at 0.2g / L to the pasty mulberries pretreated in step 1), and ferment at 28°C for 4 hours in a closed environment; then add wine yeast 71B at 3g / L for anaerobic fermentation treatment 48 hours; add malic acid during enzymolysis and fermentation to control the pH within 4-4.5.

[0061] 3) The material is then freeze-dried, the freeze-drying vacuum degree is 0.2MPa, and the temperature is minus 12°C. The freeze-dried dry product is first crushed and then ultrafinely pulverized at low temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com