Test device and method for measuring axial compression performance of composite material pipe for structural engineering

A technology for composite materials and structural engineering, applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the problem of non-linearity, narrow end plate grooves, and difficulty in adapting to the diameter of fiber-wound pipes Changes in wall thickness and other issues, to achieve the effect of convenient operation, wide applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention will be described in further detail below in conjunction with specific embodiments.

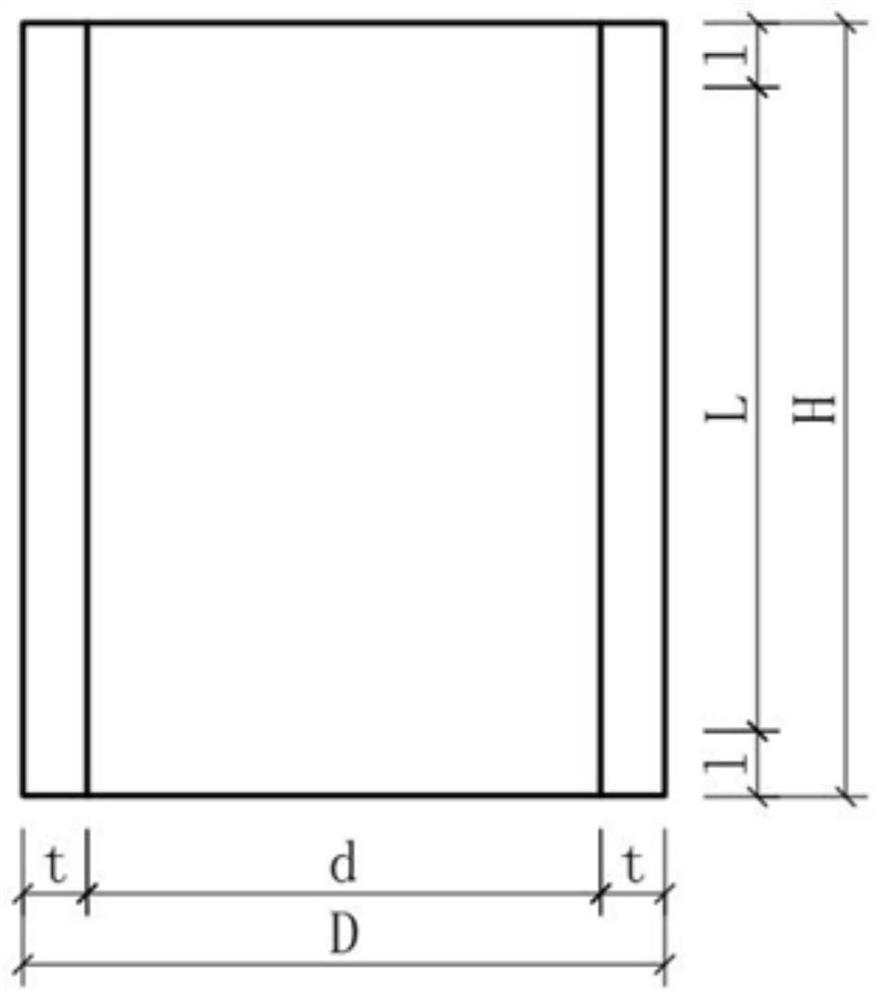

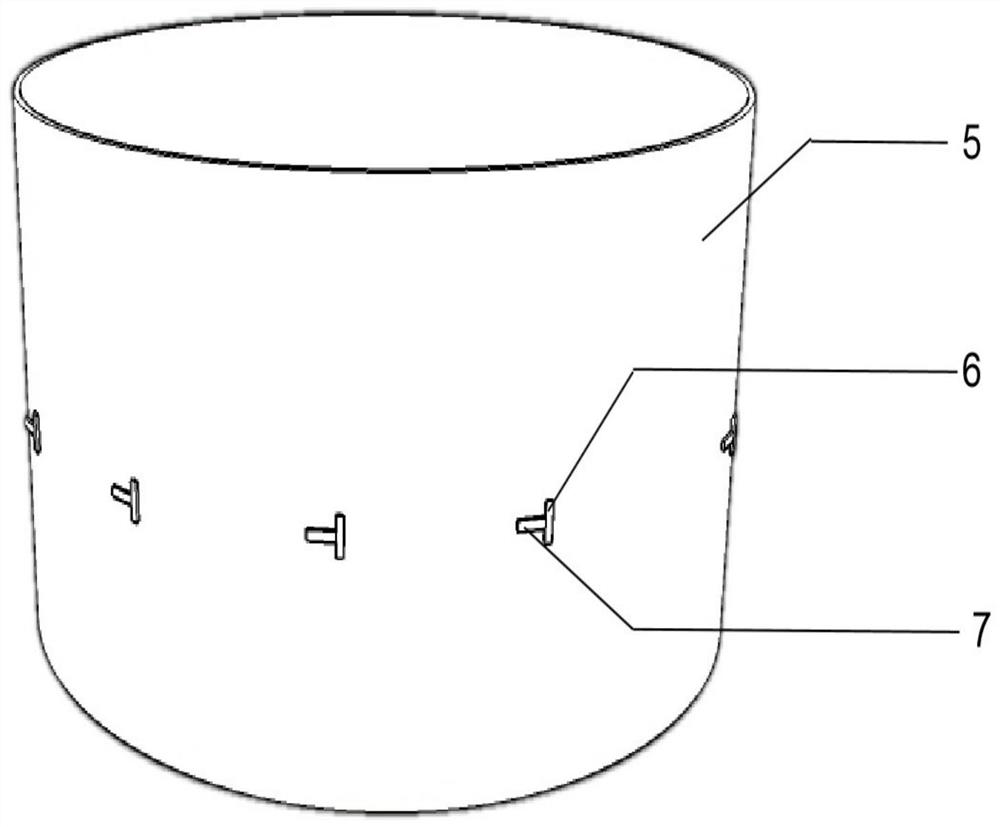

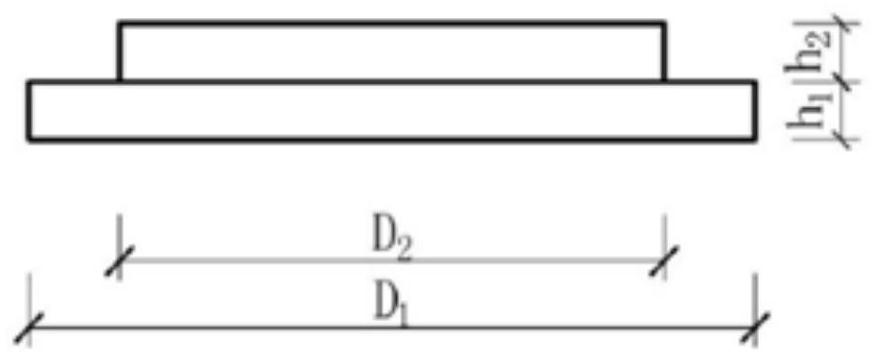

[0108] A test device for measuring the axial compressive properties of composite pipes for structural engineering, including upper end plates, lower end plates, semicircular steel bars, axial strain gauges, and hoop strain gauges. The structure of the upper end plate and the lower end plate is the same, including a circular end plate and a cylindrical protrusion in the center of the end plate. The shape protrusion forms an annular groove, in which the position of the semi-circular steel bar is positioned according to the diameter and wall thickness of the tubular sample to adapt to the fluctuation of the sample diameter and the change of the wall thickness; the compression sample is tubular , the polished ends are placed in the grooves of the upper and lower end plates, respectively, and the sample is fixed on the upper and lower end plates by filling the groove w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com