Nodeless screen printing plate based on stainless steel plate

A stainless steel plate, no node technology, applied in screen printing machines, rotary printing machines, printing, etc., can solve the problems of affecting the life of screen printing, leakage of printing debris, and great influence on strength, etc., to achieve good current collection and Transmission ability, small printing resistance, good surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

[0021] 1. Specific examples

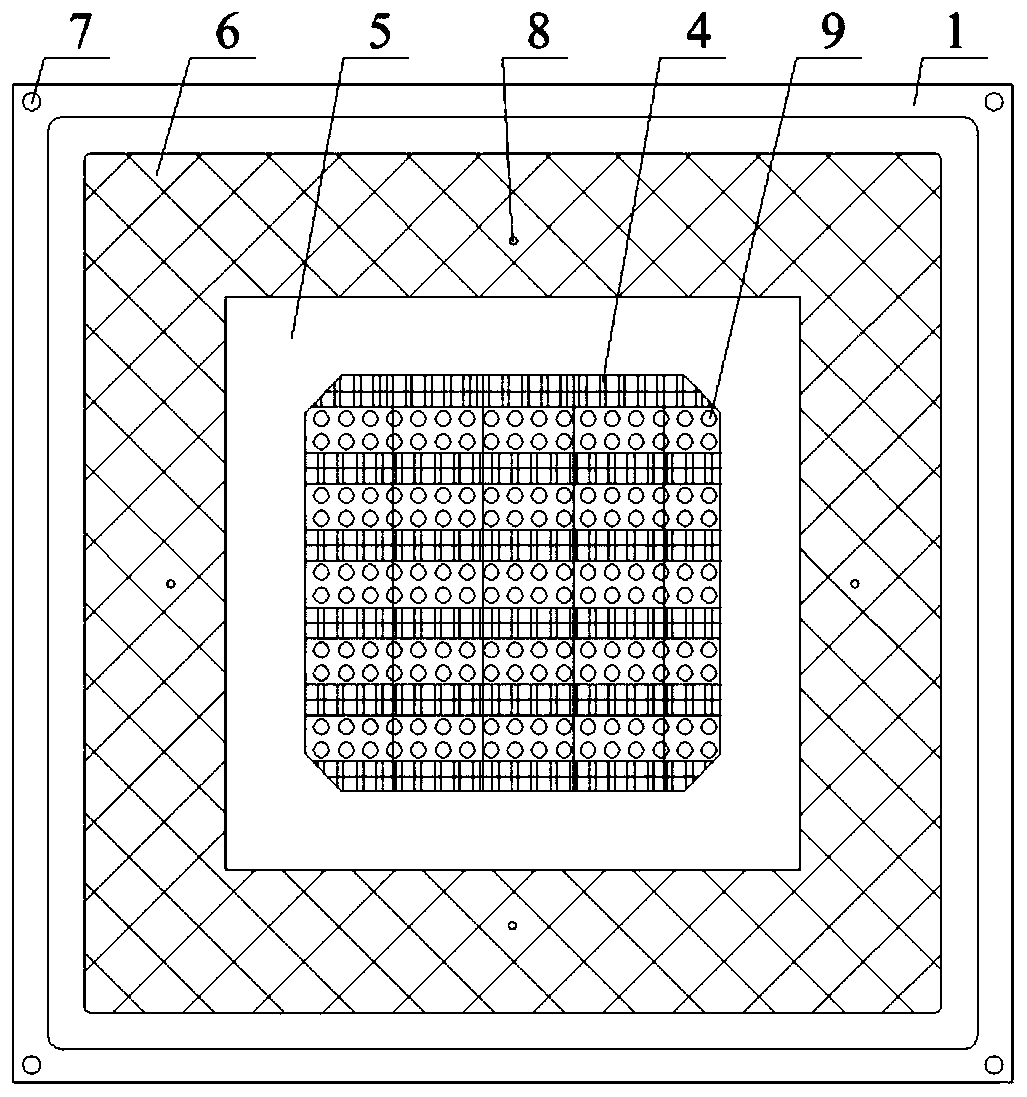

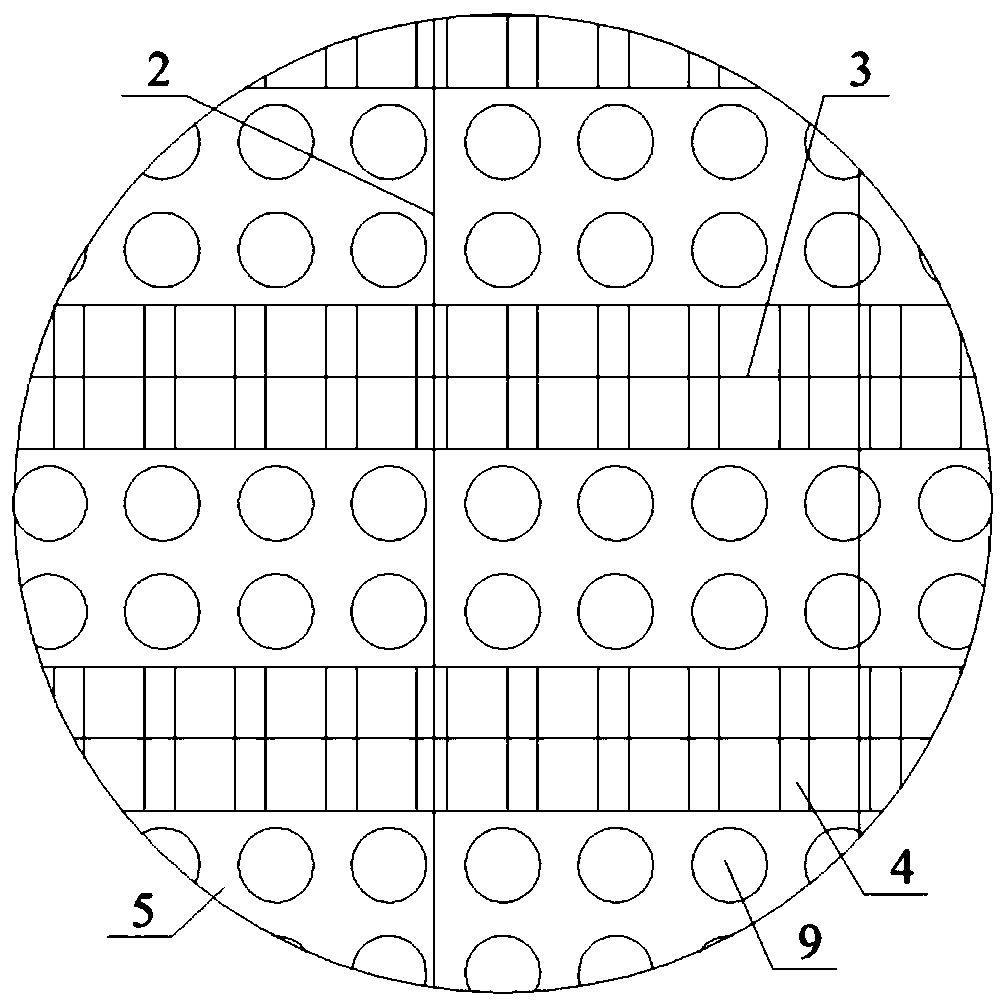

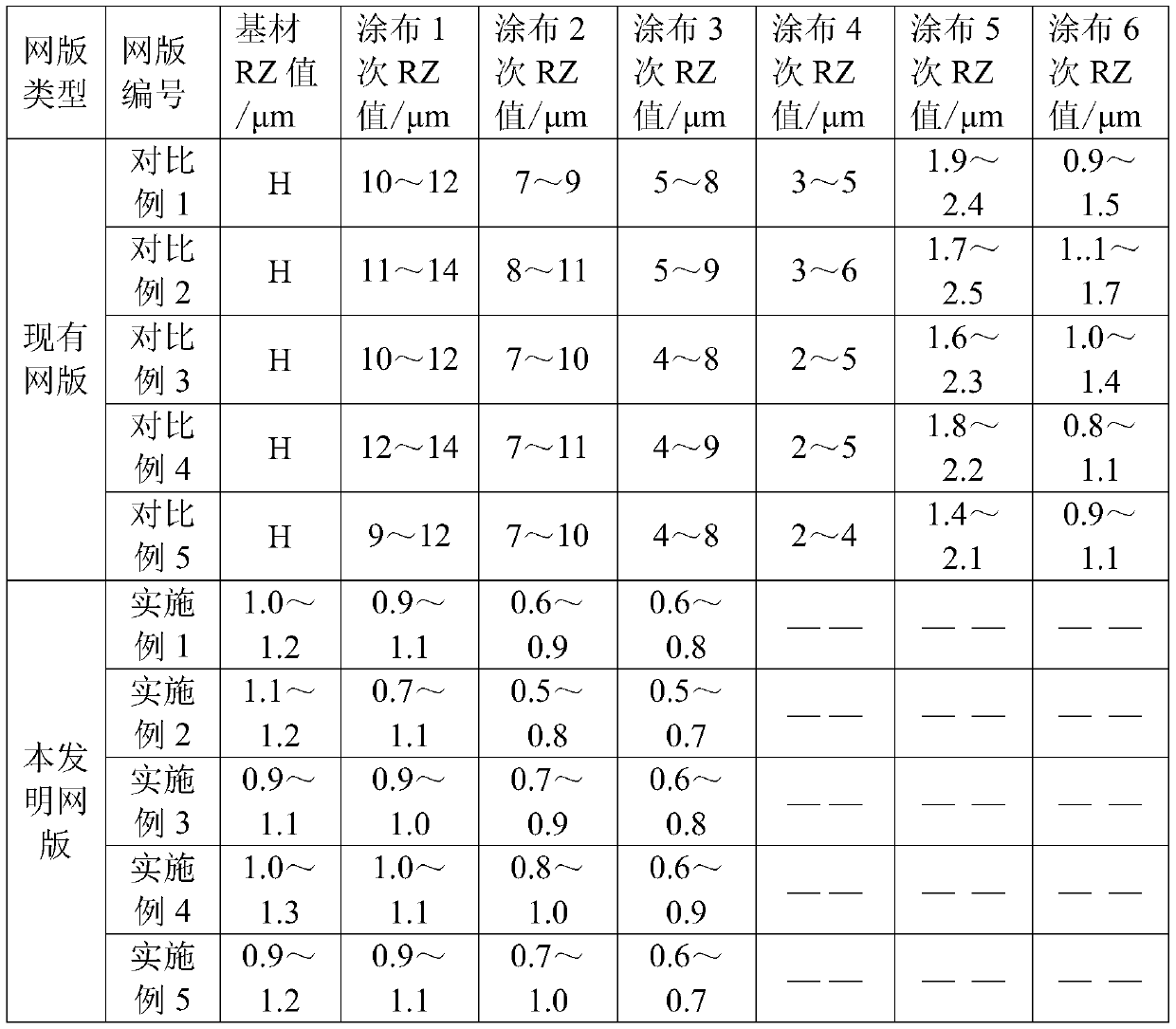

[0022] A nodeless screen based on a stainless steel plate, including a screen frame 1 and a carrier stretched inside the screen frame 1. A group of parallel main grid lines 2 and a group of parallel auxiliary grid lines are arranged at the center of the carrier. 3 and a group of via holes 4 for passing the slurry, the main grid line 2 and the sub grid line 3 are arranged vertically, such as figure 1 with figure 2 As shown, the main grid lines 2 are arranged vertically, the auxiliary grid lines 3 are arranged horizontally, the via holes 4 are rectangular holes, and a group of rectangular holes are opened on the periphery of each auxiliary grid line 3 along the length direction, and the auxiliary grid lines 3 are located at At the center of the length side of the rectangular hole, the line width of the auxiliary grid line ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com