Deep ultraviolet LED chip and preparation method thereof

An LED chip, deep ultraviolet technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems affecting the contact performance of N-type ohmic contact electrodes, chip current accumulation, damage to ohmic contacts, etc., to improve light extraction efficiency, avoid Influence each other and reduce the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

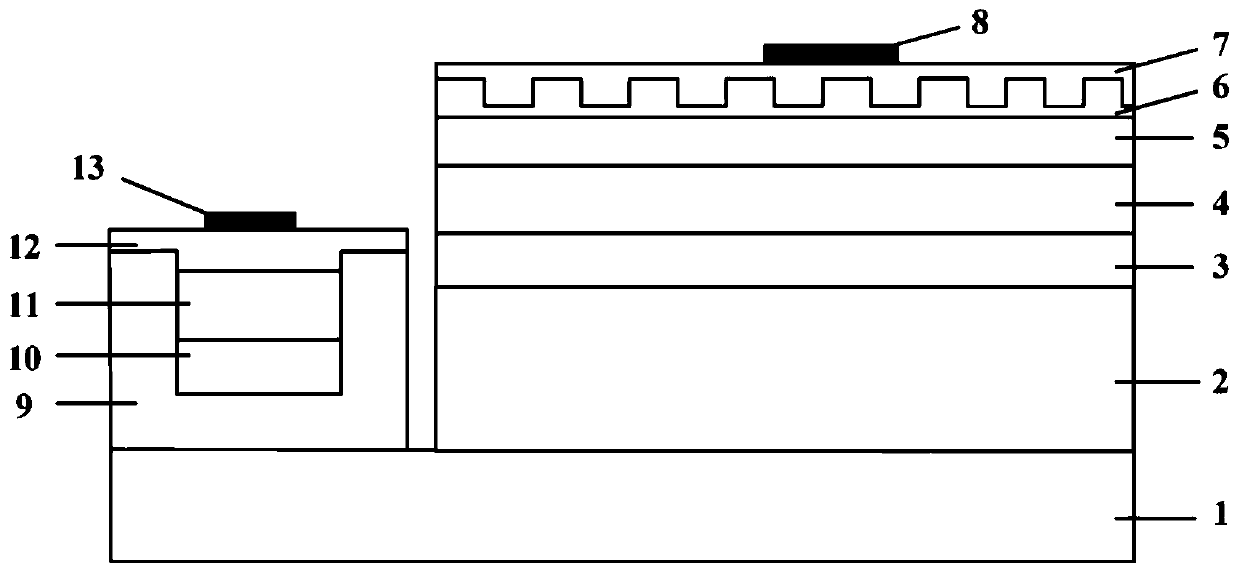

[0073] The structure and specific implementation steps of the deep ultraviolet LED chip provided by Embodiment 1 of the present invention are as follows:

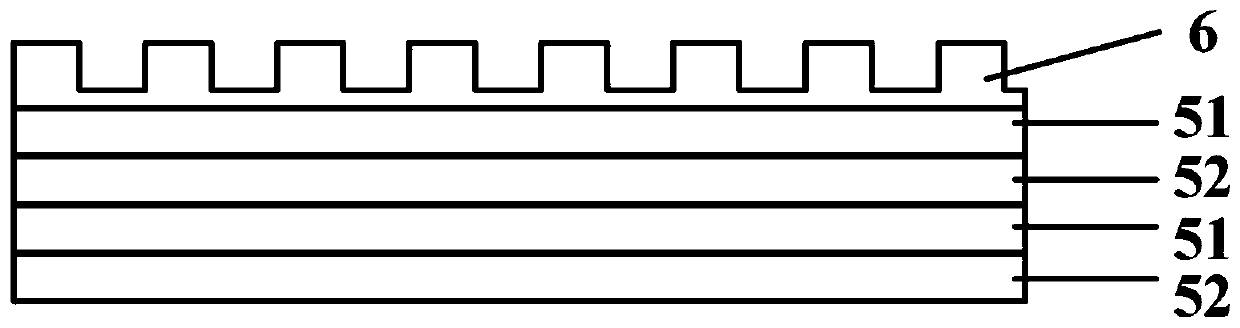

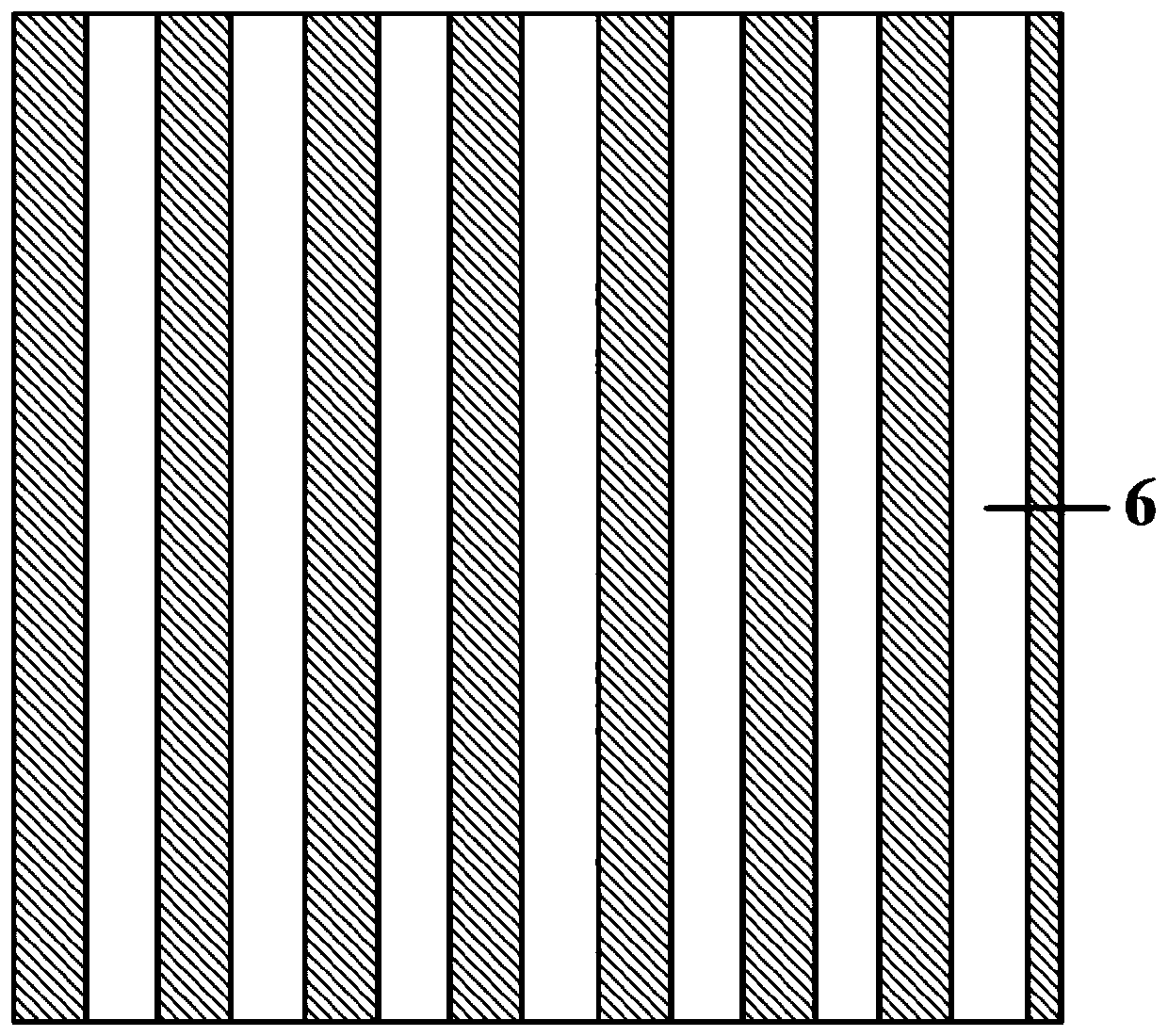

[0074] (1) Prepare conductive substrate 1, and divide P electrode area and N electrode area on conductive substrate 1; On the P electrode area of conductive substrate 1, grow the epitaxial structure of deep ultraviolet LED chip, prepare P electrode, conductive lining Bottom 1 can be made of SiC, P-type doped Si and other materials, refer to figure 1 , the epitaxial structure includes: N-type AlGaN layer 2 , multiple quantum well layer 3 , P-type AlGaN layer 4 , AlN / GaN superlattice ohmic contact layer 5 , and P-type GaN layer 6 . refer to figure 2 , wherein the AlN / GaN superlattice ohmic contact layer 5 is composed of atomically thick AlN layers 51 and GaN layers 52 arranged alternately, and the AlN layer 51 and GaN layer 52 can be doped with Mg to improve the ohmic contact performance, and the P-type GaN The thickness...

Embodiment 2

[0086] The structure and specific implementation steps of the deep ultraviolet LED chip provided by Embodiment 2 of the present invention are as follows:

[0087] (1) Prepare the conductive substrate 14, and divide the P electrode region and the N electrode region on the conductive substrate 1; grow the epitaxial structure of the deep ultraviolet LED chip on the insulating substrate 31, prepare the P electrode, and the insulating substrate 31 can adopt Sapphire, SiO 2 material, see Figure 5 , and its structure includes: N-type AlGaN layer 2, multiple quantum well layer 3, P-type AlGaN layer 4, AlN / GaN superlattice ohmic contact layer 5, and P-type GaN layer 6. refer to figure 2 , wherein the AlN / GaN superlattice ohmic contact layer 5 is composed of atomically thick AlN layers 51 and GaN layers 52 alternately arranged, and the AlN layer 51 and GaN layer 52 can be doped with Mg to improve the ohmic contact performance. The thickness of the p-type GaN layer 6 is 10-15 nm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com