MEMS universal inertia switch capable of identifying load orientation interval

An inertial switch and azimuth technology, which is applied in the direction of electric switches, contacts, electrical components, etc., can solve the problems of complex structure and inability to recover automatically, and achieve the effects of enhancing contact effect, preventing excessive displacement, and prolonging closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

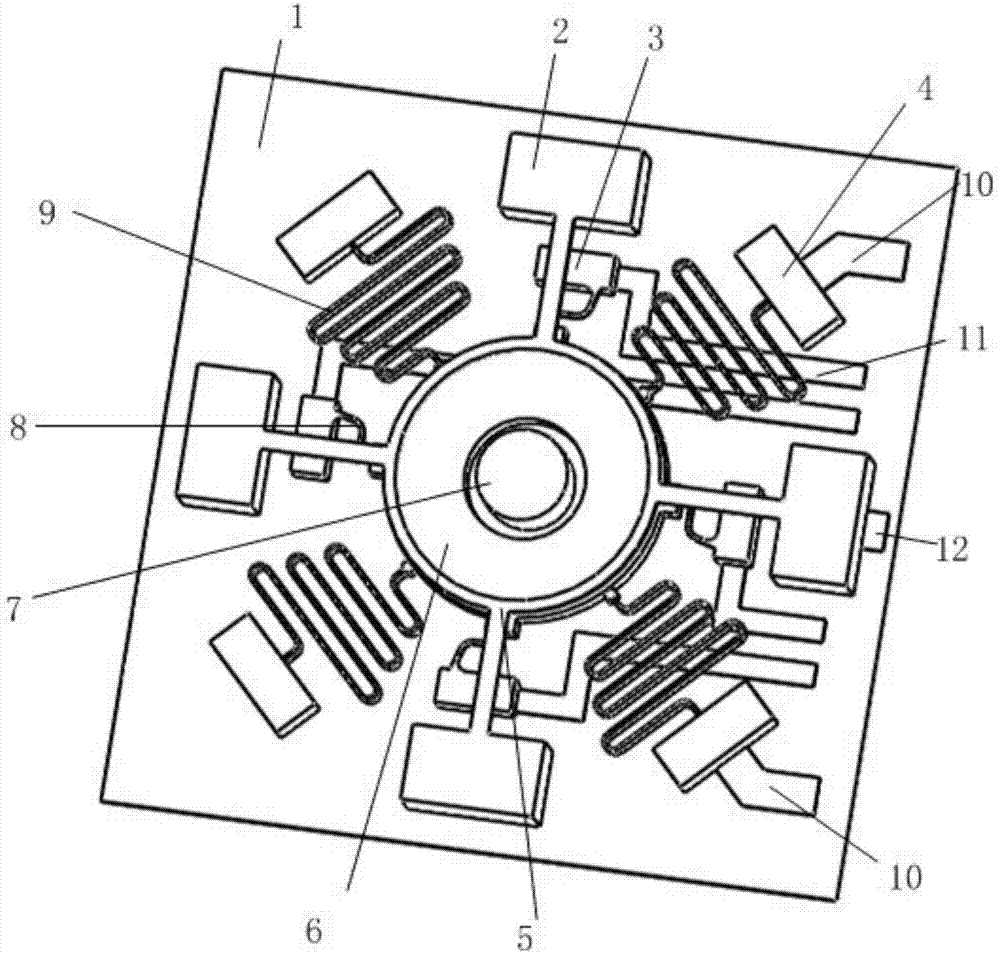

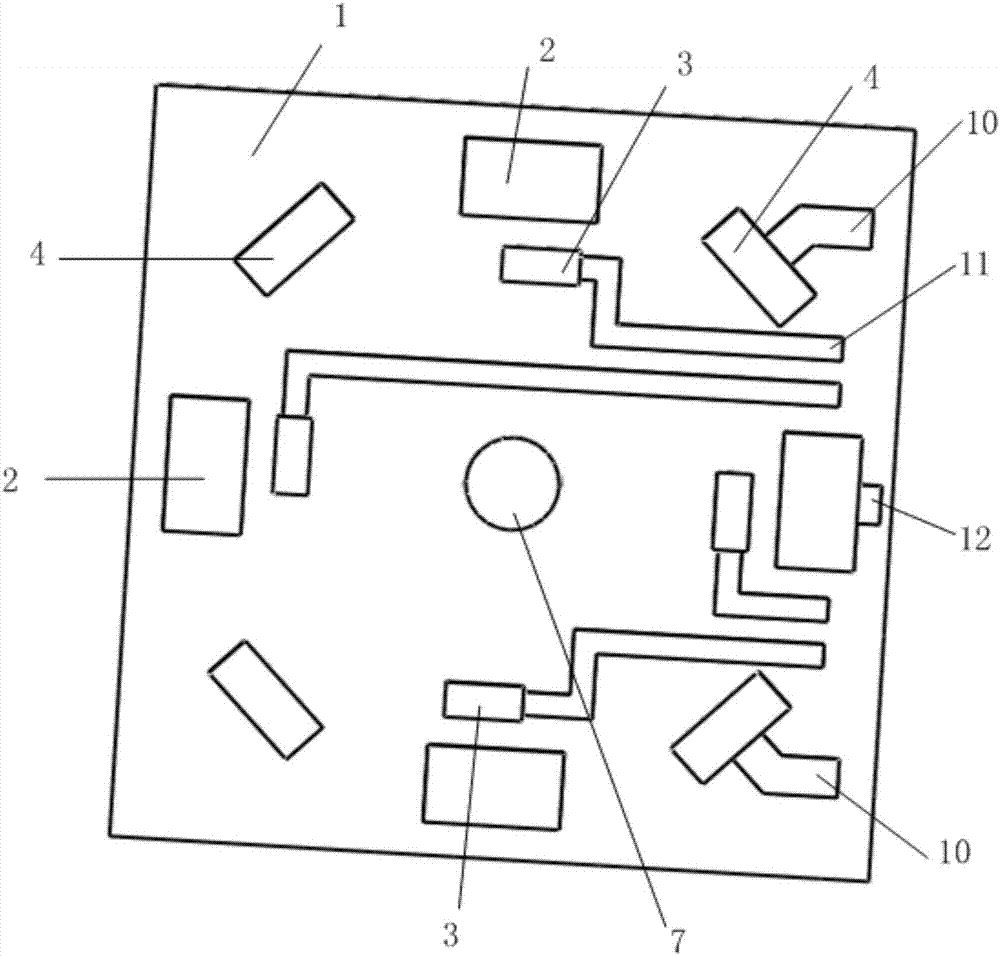

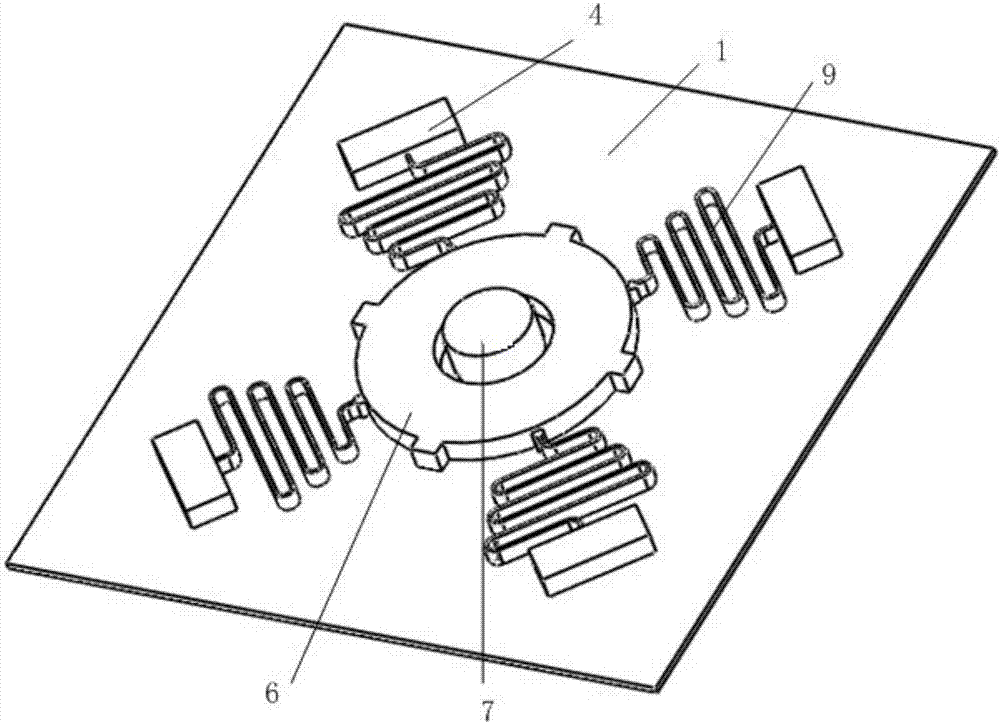

[0042] combine Figure 1 to Figure 5 , a MEMS universal inertial switch capable of identifying load azimuth intervals, including an insulating substrate 1, an axial electrode support seat 2, a radial electrode support seat 3, a spring support seat 4, an axial electrode 5, and an annular inertial mass electrode 6. Limit stop column 7, radial electrode 8, serpentine support spring 9, radial electrode connecting strip 11, axial electrode connecting strip 12 and two mass block electrode connecting strips 10, axial electrode support seat 2, The radial electrode support seat 3, the spring support seat 4, the limit stop post 7, the mass electrode connection strip 10, the radial electrode connection strip 11 and the axial electrode connection strip 12 are all arranged on the insulating substrate 1, and the axial The electrode support seat 2, the radial electrode support seat 3 and the spring support seat 4 are all used as anchor points; the limit stopper column 7 is located at the cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com