Prefabricated supporting pipe piece inverted 'T'-shaped excavation method and temporary supporting structure adopted by urban shallow buried large-section tunnel

A support structure and temporary support technology, which is applied in the direction of tunnels, tunnel linings, temporary shields, etc., can solve the problems of unsuitable for green construction, material saving, energy saving, large amount of temporary support construction removal, and environmental pollution in tunnels. Achieve the effects of reducing construction time and concrete strength curing time, avoiding settlement and convergence deformation, and reducing tunnel safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention are given below. It should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations made on the basis of the technical solutions of the present application fall into the protection scope of the present invention.

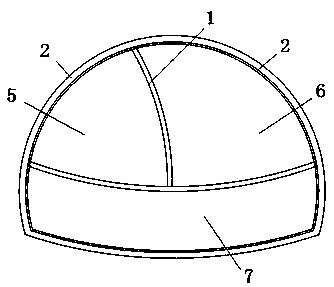

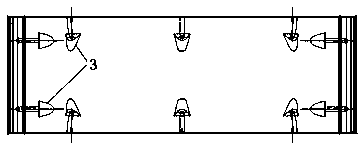

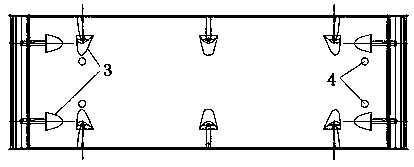

[0026] The urban shallow-buried large-section tunnel of the present invention adopts the inverted "T" shape excavation method of prefabricated support segments as follows: the upper steps are excavated in two steps, and the left and right sides are separated by a certain distance, so as to reduce the need for one-time excavation of the soil body on the face of the tunnel. After the excavation of the upper step is completed, a closed loop is formed, and then the lower step 7 is excavated. No temporary vertical support is erected during the excavation of the lower step 7, which is used to improve the efficiency and speed up the tunnel landing and full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com