Sleeved inner liner reinforcing structure for electrical operation of cable tunnel and construction method thereof

A cable tunnel and reinforcement structure technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of unable to prevent the disease from continuing to develop, the reinforcement space is small, and it is difficult to deal with the disease, so as to achieve normal live operation and simple construction steps. , Solve the effect of poor reinforcement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

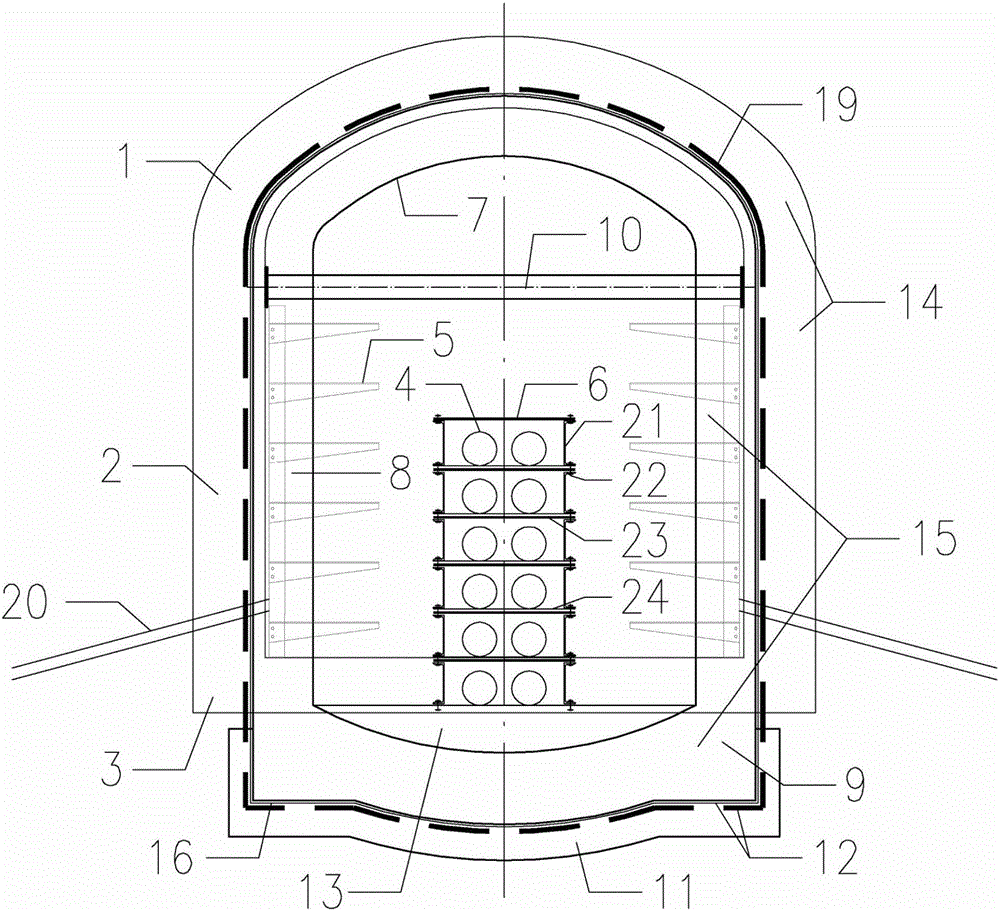

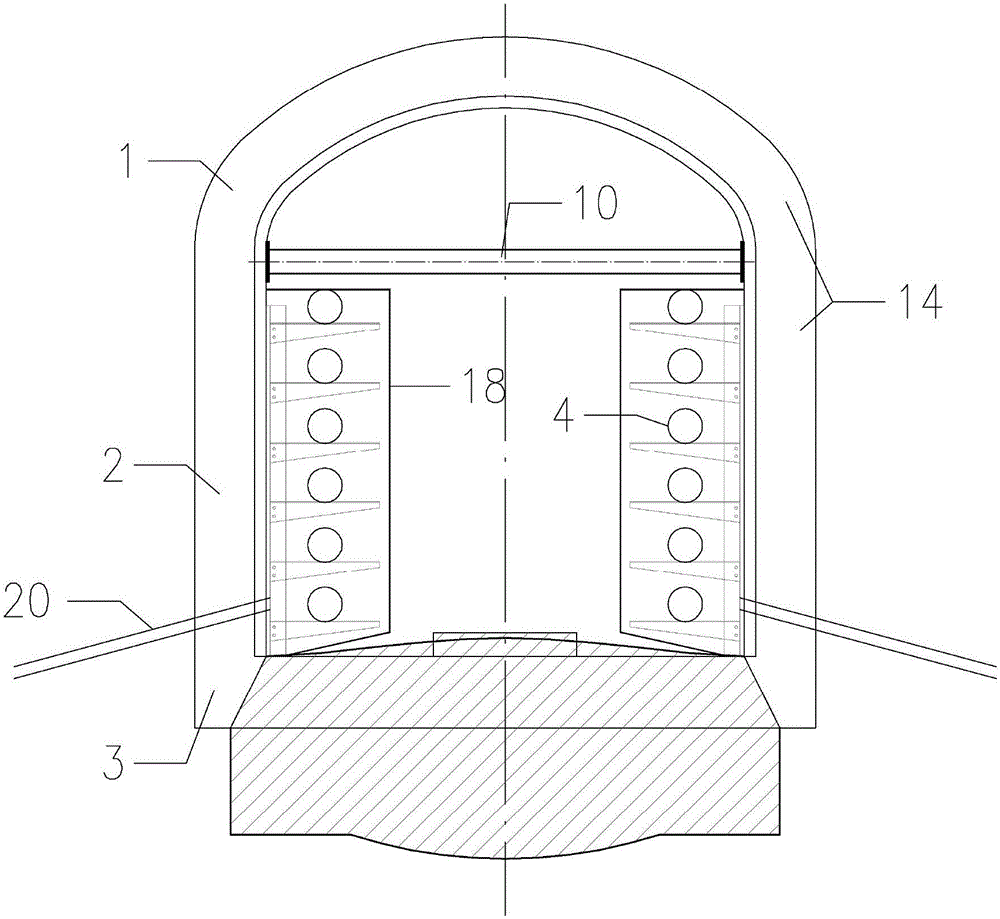

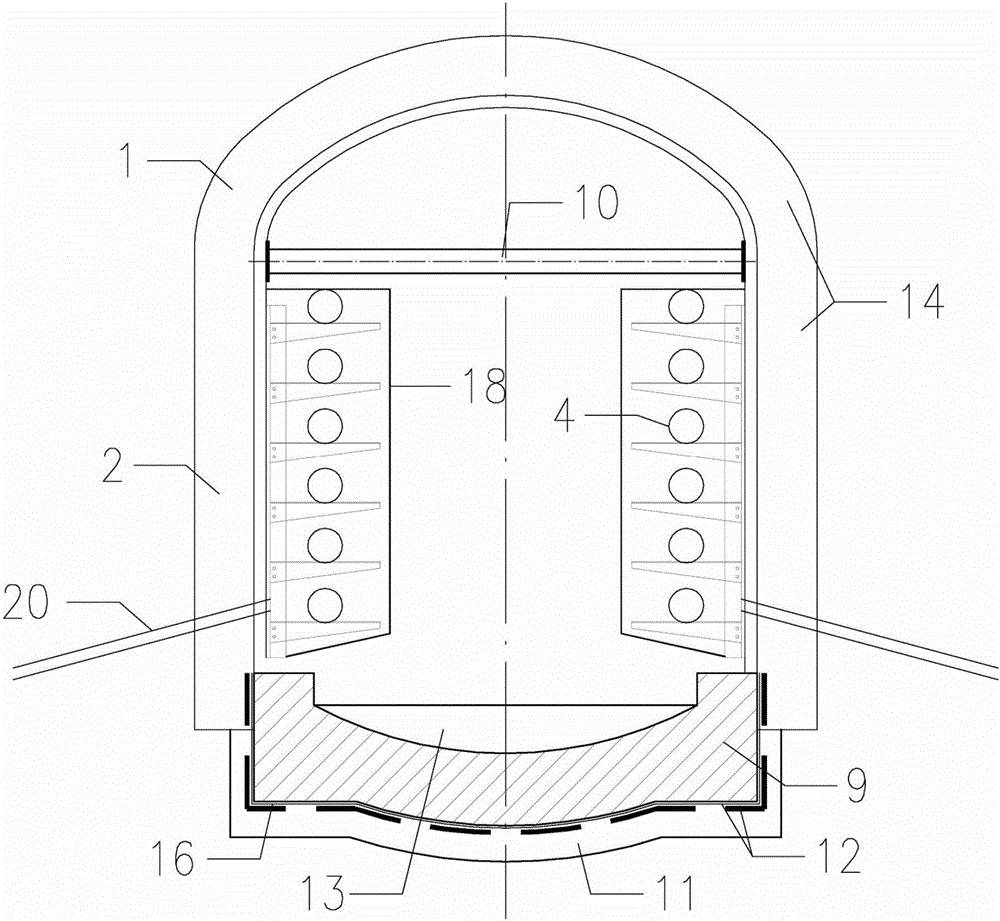

[0037] Such as Figure 1-6 As shown in the figure, a cable tunnel is equipped with a lining reinforcement structure for live operation, including the original arch 1, the original side wall 2, the floor cushion 11, the inverted arch 9, the lining arch 7, the lining side wall 8, and the cable bracket 5. Cable 4, sidewalk floor 13, both sides of the lower end of the original arch 1 are connected with the upper end of the original side wall 2 to form the original tunnel inner wall 14, the floor cushion 11 is located under the original side wall 2, and the inverted arch 9 is arranged on the floor cushion In the layer 11, both sides of the upper end of the inverted arch 9 are connected to the lower end of the original side wall 2, the inner lining arch 7 is arranged on the inner side of the original arch 1, and the inner lining side wall 8 is arranged on the inner side of the original side wall 2. The upper end of the lining wall 8 is connected to the lining arch 7 and its lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com