Wall corner crack repairing method

A technology for repairing cracks and corners, applied in building maintenance, construction, building construction, etc., can solve problems such as cracks in corners, improve strength, reduce the probability of cracking again, and achieve the effects of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

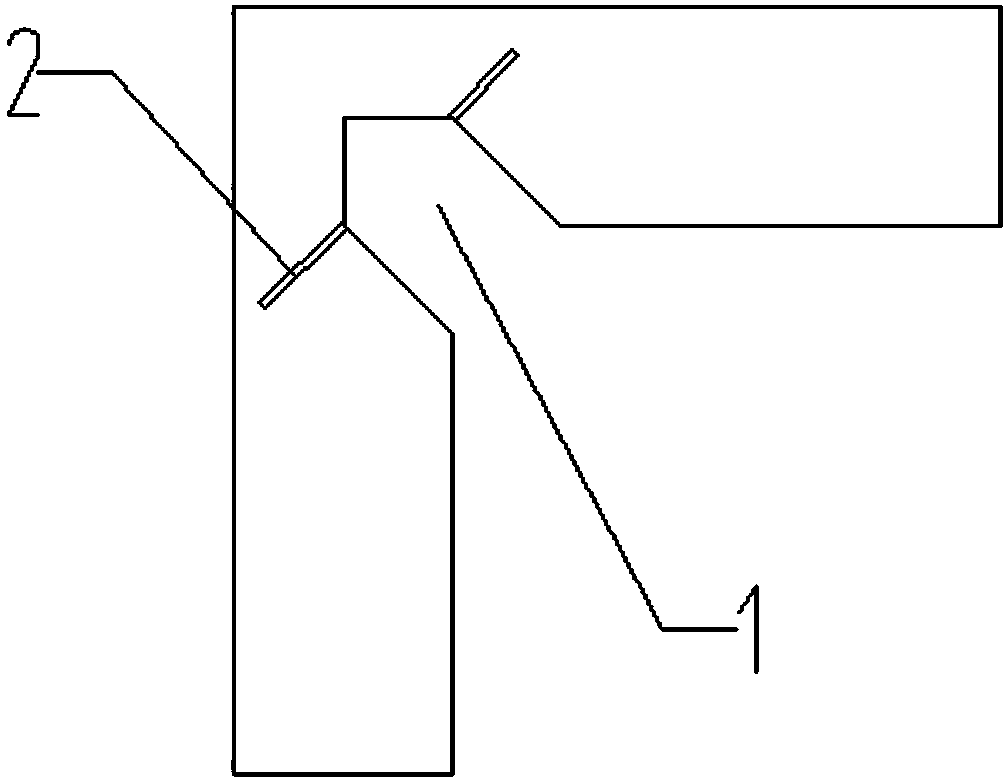

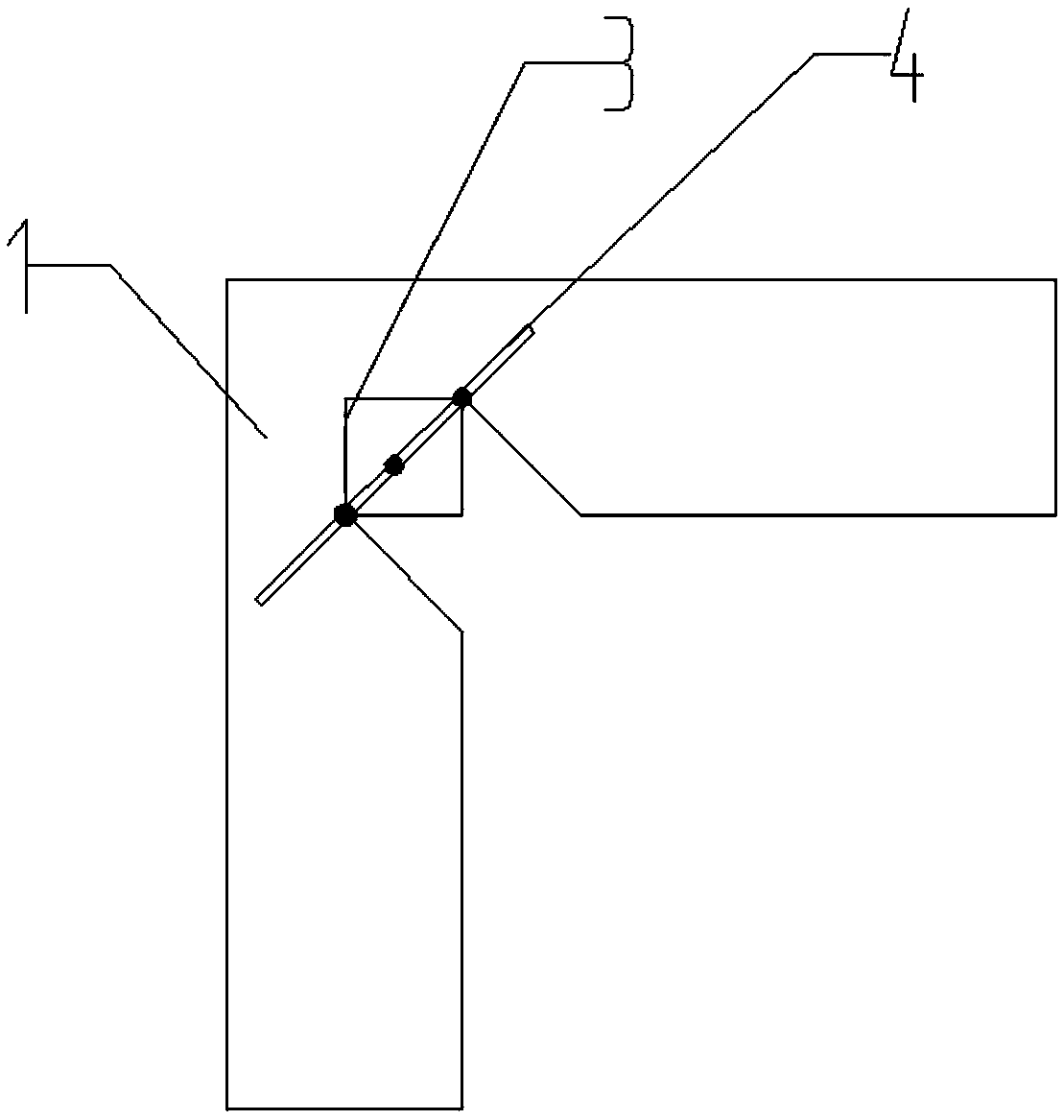

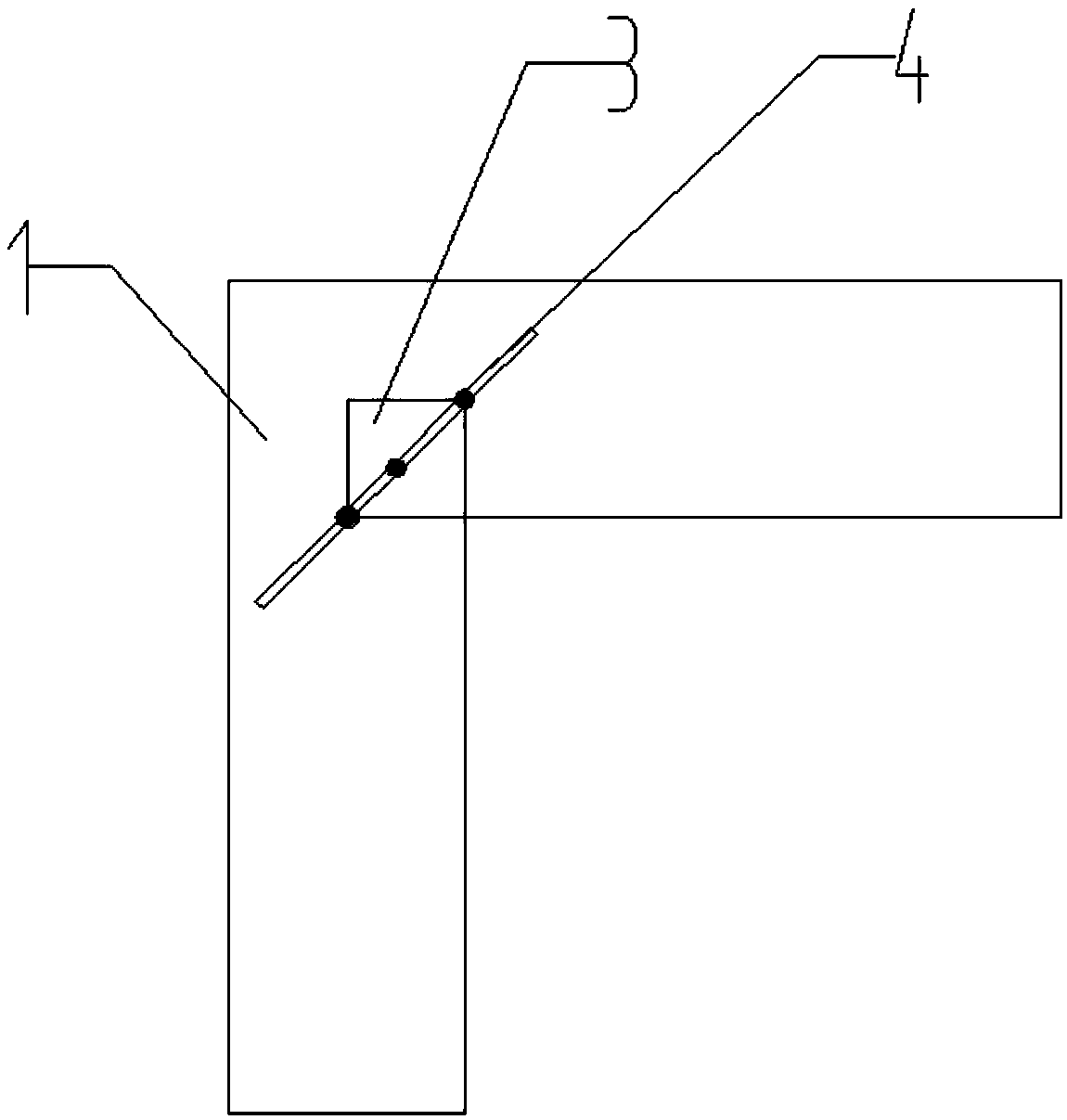

[0024] Such as Figure 1 to Figure 4 Shown, a kind of wall corner crack repair method, comprises the following steps:

[0025] Step 1: Find the location of the crack in the corner of the wall, and then dig a repair groove 1 at the crack. After repairing the groove 1, the contact area between the repairing cement and the wall can be increased, and after opening the repair groove 1, the gap between the two walls can be increased. Leave enough space to place connecting square pipe 3 and excavate reinforcement hole 2.

[0026] Step 2: Dig reinforcement holes 2 on both sides of the repair groove 1, and drill reinforcement holes 2 on the side of the repair groove 1 with tools such as an electric drill, so that the reinforcement bars 4 can enter the wall.

[0027] Step 3: Put the connecting square pipe 3 in the repair groove 1, drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com