Wear-resistant tensile steel wire rope preparation method

A steel wire rope and wire drawing technology is applied in the field of preparation of wear-resistant and tensile-resistant steel wire ropes, which can solve the problems of reducing the wear resistance and flexibility of the steel wire rope, accelerating the corrosion and aging of the steel wire rope, affecting the wear-resisting and tensile properties of the steel wire rope, and improving the flexibility. , prolong the service life, and facilitate the effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

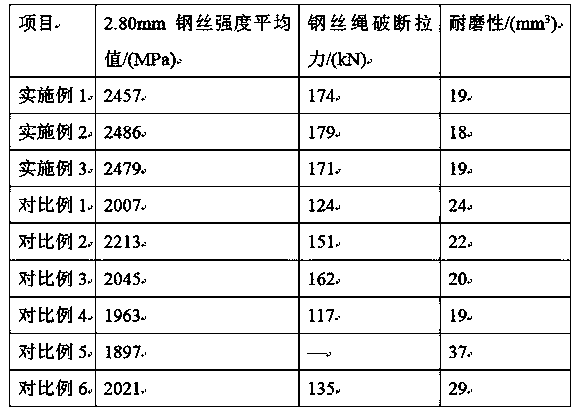

Embodiment 1

[0031] A method for preparing a wear-resistant and tensile steel wire rope, comprising the following steps:

[0032] (1) Selection of raw materials: Select qualified high-carbon carbon steel and alloy steel to improve the applicability of steel wire ropes to different environments, and obtain unprocessed carbon steel and unprocessed alloy steel; the above-mentioned carbon steel is ordinary carbon steel Steel, with a carbon content of 0.97%; the alloy steel is 3.13% by weight of silicon, 2.03% of manganese, 1.73% of boron, 1.65% of titanium, 1.16% of chromium, 0.95% of nickel, Vanadium 0.81%, Cobalt 0.72%, Molybdenum 0.61%, Zirconium 0.36%, Niobium 0.16%;

[0033] (2) Surface derusting: Put the untreated carbon steel and the untreated alloy steel in the derusting solution, soak at 50°C for 40 minutes, and then ultrasonicate at 35kHz for 30 minutes, which can facilitate post-processing and avoid damage to the processing machinery. Rust-removing carbon steel and rust-removing al...

Embodiment 2

[0050] A method for preparing a wear-resistant and tensile steel wire rope, comprising the following steps:

[0051] (1) Selection of raw materials: Select qualified high-carbon carbon steel and alloy steel to improve the applicability of steel wire ropes to different environments, and obtain unprocessed carbon steel and unprocessed alloy steel; the above-mentioned carbon steel is ordinary carbon steel Steel, with a carbon content of 1.18%; the alloy steel is 3.15% by weight of silicon, 2.09% of manganese, 1.82% of boron, 1.69% of titanium, 1.21% of chromium, 0.98% of nickel, Vanadium 0.86%, Cobalt 0.77%, Molybdenum 0.65%, Zirconium 0.41%, Niobium 0.19%;

[0052] (2) Surface derusting: Put the untreated carbon steel and the untreated alloy steel in the derusting solution, soak at 53°C for 45 minutes, and then ultrasonicate at 36kHz for 33 minutes, which can facilitate post-processing and avoid damage to the processing machinery. Rust-removing carbon steel and rust-removing al...

Embodiment 3

[0069] A method for preparing a wear-resistant and tensile steel wire rope, comprising the following steps:

[0070] (1) Selection of raw materials: Select qualified high-carbon carbon steel and alloy steel to improve the applicability of steel wire ropes to different environments, and obtain unprocessed carbon steel and unprocessed alloy steel; the above-mentioned carbon steel is ordinary carbon steel Steel, with a carbon content of 1.32%; the alloy steel is 3.21% by weight of silicon, 2.17% of manganese, 1.97% of boron, 1.77% of titanium, 1.31% of chromium, 1.02% of nickel, Vanadium 0.93%, Cobalt 0.84%, Molybdenum 0.72%, Zirconium 0.49%, Niobium 0.23%;

[0071] (2) Surface derusting: put the untreated carbon steel and the untreated alloy steel in the derusting solution, soak at 55°C for 50 minutes, and then ultrasonicate at 37kHz for 35 minutes, which can facilitate post-processing and avoid damage to the processing machinery. Rust-removing carbon steel and rust-removing al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com