Single-station RH process arrangement method for rail crossing of two molten steel vehicles

A layout method and a molten steel car technology, applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of high energy consumption by alternating cold and hot, and the influence of cold steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

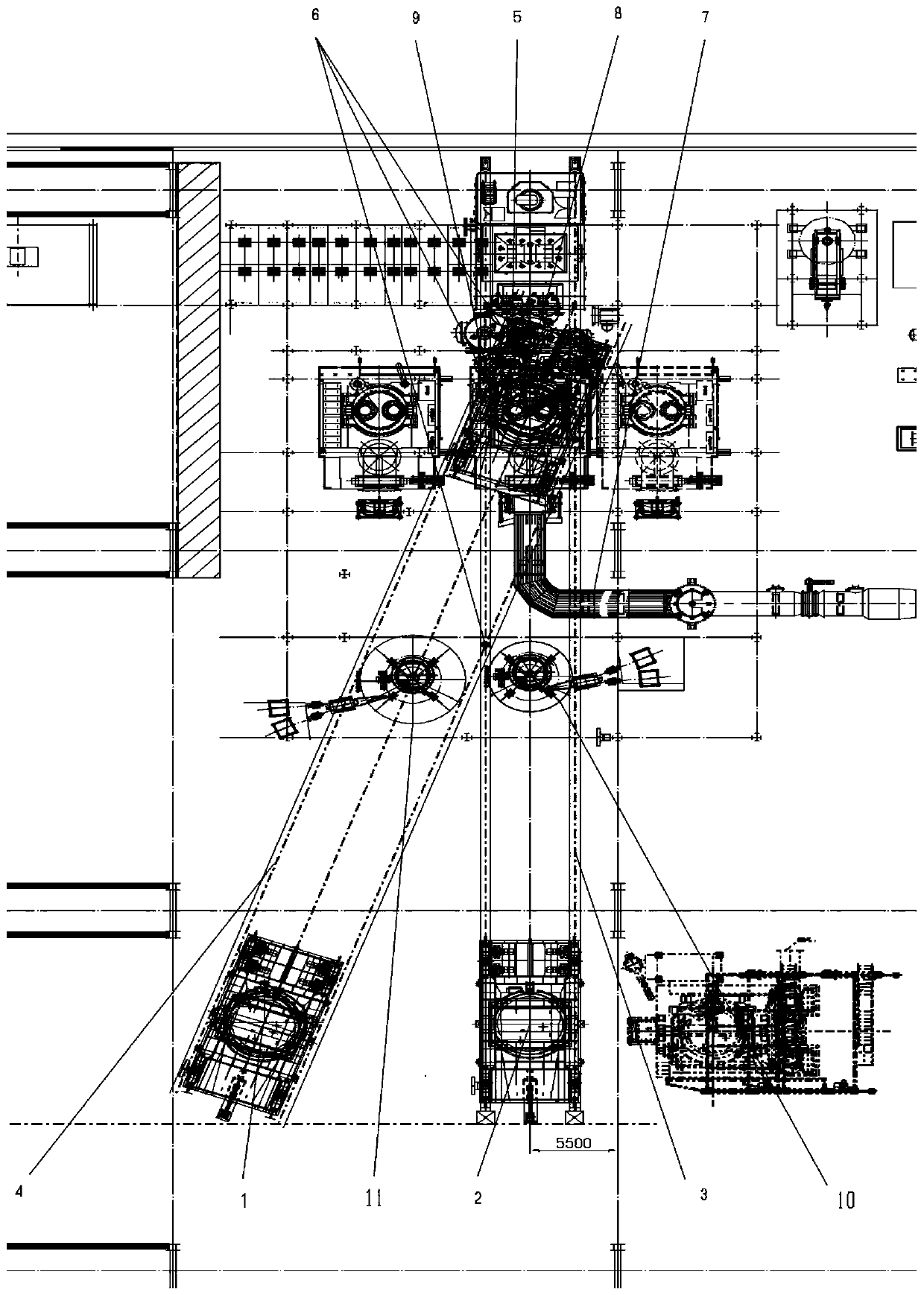

[0025] The present invention provides a single-station RH process arrangement method in which two steel car tracks are crossed. Two steel car tracks are used. One of the steel car tracks is a special-shaped steel car. There is an angle between the track layout and the center line of the processing station. The steel car is a conventional-shaped steel car, and its track center line is the same as the center line of the processing position. There is an intersection when the two steel car tracks run to the processing position. After the ladle molten steel treatment on one steel car is completed, in addition A ladle steel car is opened to the processing position to continue processing, which can shorten the RH idle time and reduce the heat loss in the vacuum tank. At the same time, it achieves the purpose of continuous production and supply of a continuous casting machine.

[0026] The present invention will be further explained below in conjunction with examples and drawings.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com