Different-diameter synchronous-coupled blast furnace tuyere injecting device and injecting method

A technology of synchronous coupling and injection device, applied in the direction of the tuyere, can solve the problems of not considering the reduction of thermal efficiency, energy saving and efficiency improvement, etc., to achieve the effect of large firing range, optimized coking coal ratio, and increased injection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

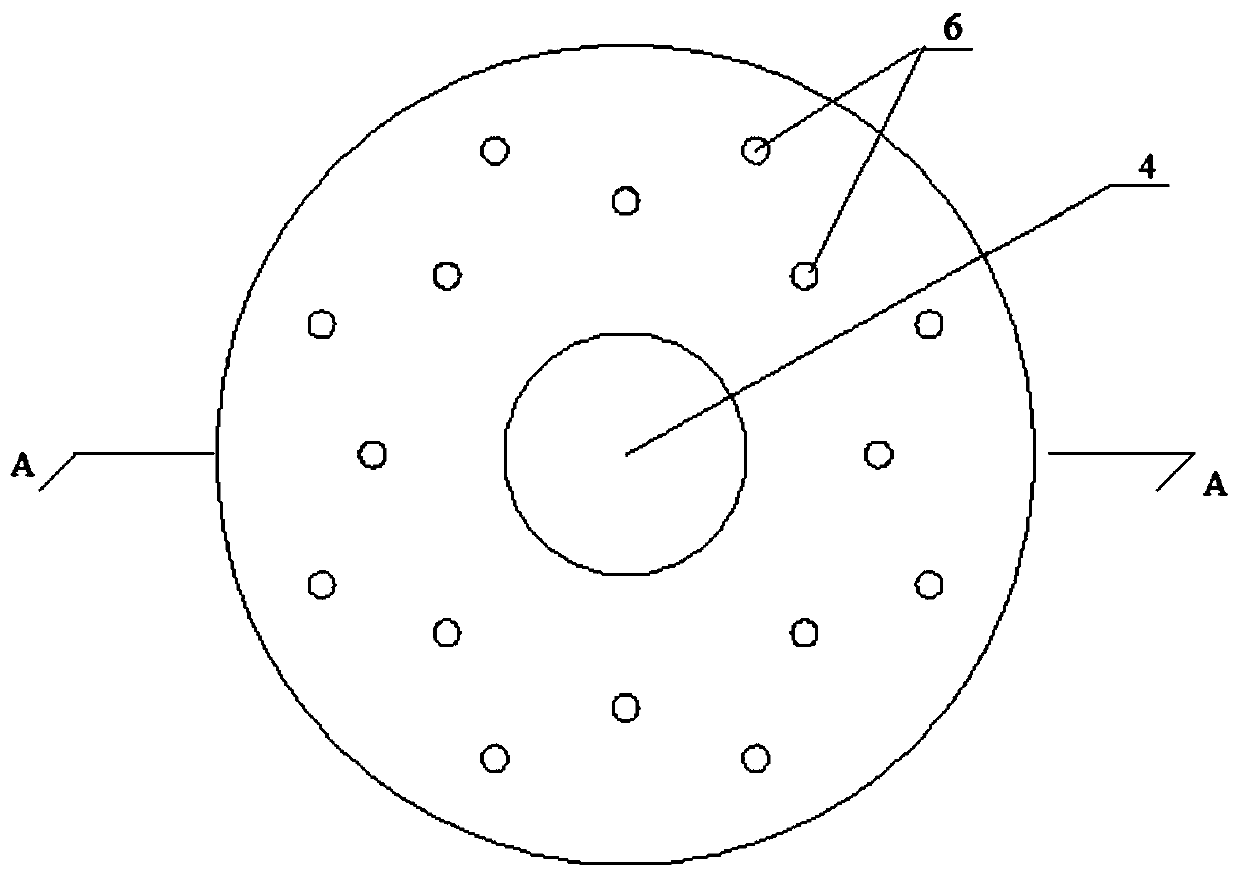

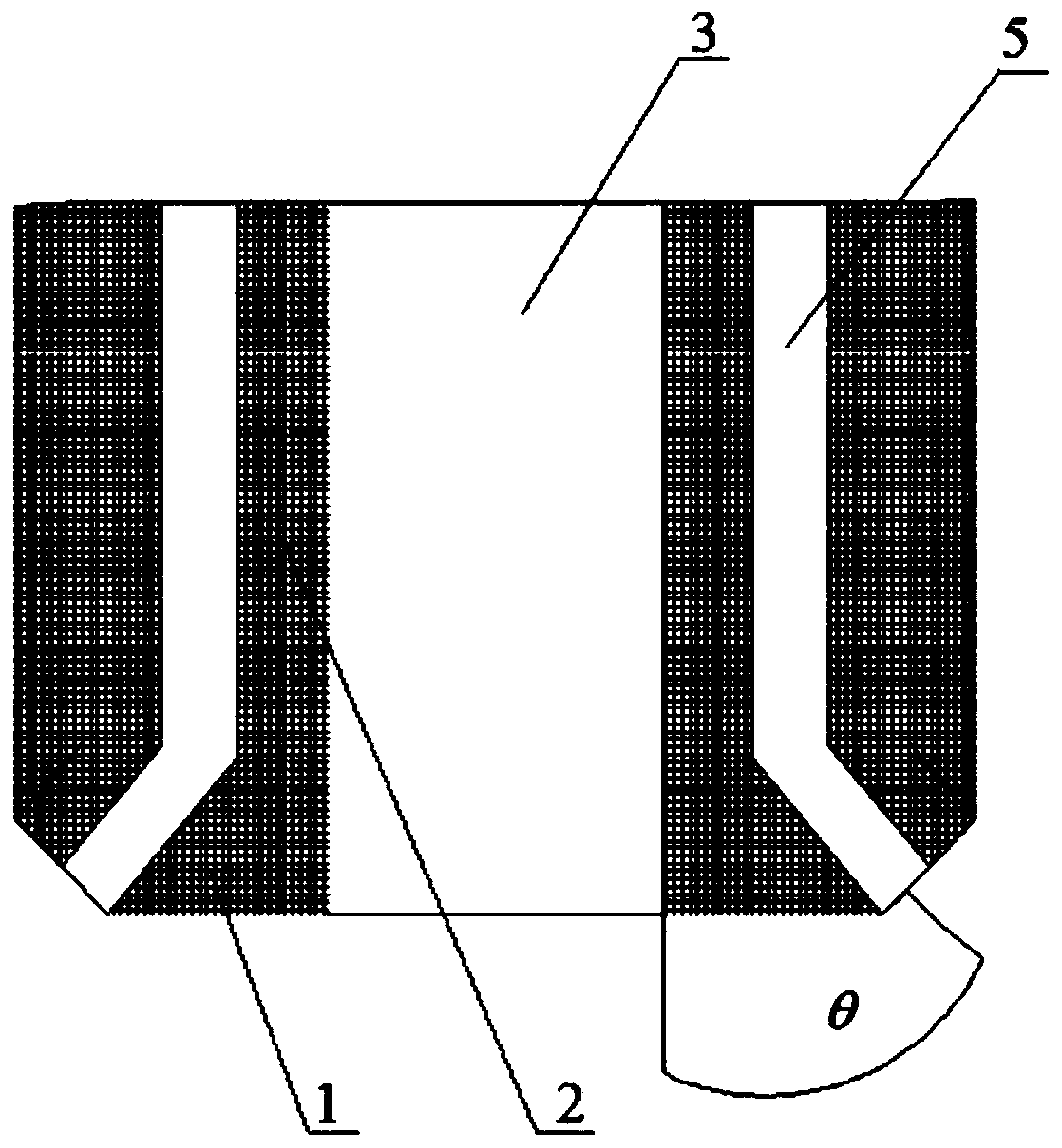

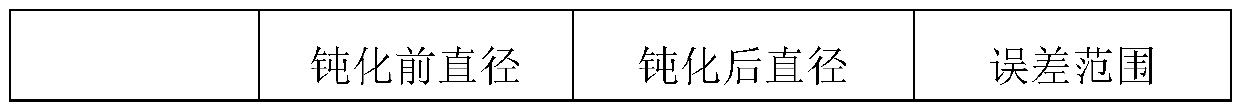

[0029] A different-diameter synchronously coupled blast furnace tuyere injection device, which consists of a nozzle 1 and an injection body 2 connected to the nozzle. The nozzle 1 is in the shape of a truncated cone or one end is a truncated cone and the other end is cylindrical, and the injection body 2 is a cylinder. The axis of the blowing body is provided with a main nozzle 3 and the main nozzle extends to the nozzle to form the main nozzle 4, and several secondary nozzles 5 are evenly distributed around the main nozzle and the secondary nozzle extends to the nozzle to form the secondary nozzle 6, The auxiliary nozzle is bent at the junction of the nozzle and the injection body, forming an angle of θ≤30° with the axial direction of the injection body; the diameter of the injection body is Φ=50-200mm, and the length of the main nozzle is 0.2-10m. The diameter of the main nozzle is Φ=20-70mm, the diameter of the auxiliary nozzle is Φ=10-20mm, there are 4-16 auxiliary nozzles,...

Embodiment 2

[0032] Using the different-diameter synchronous coupling blast furnace tuyere injection device of embodiment 1 to blast furnace volume 1200m 3 -5500m 3 , the blast furnace temperature range of 1750°C-1950°C is a method for injecting pulverized coal particles, the specific operation steps are as follows:

[0033] Physical quantity requirements of pulverized coal particles:

[0034]

[0035]

[0036] Among them, θ=30°, the length of the main nozzle is 0.32m, the diameter of the main nozzle Φ=20mm, the diameter of the auxiliary nozzle Φ=10mm, there are 16 auxiliary nozzles, and the outlet ends of the auxiliary nozzles are distributed in 2 On the concentric circle of the tube outlet.

[0037] 1) Calculate the total amount of fuel particles injected

[0038] The amount of smelting coal powder added to the blast furnace according to the process needs ranges from 120-220kg;

[0039] Take the antegrade coefficient of the blast furnace α=0.5 (the antegrade coefficient of the ...

Embodiment 3

[0047] Using the different-diameter synchronous coupling blast furnace tuyere injection device of embodiment 1 to blast furnace volume 1200m 3 -4200m 3 , the blast furnace temperature range of 950 ℃ -1200 ℃ for the method of injecting gas, the specific operation steps are as follows:

[0048] θ=6°, the length of the main nozzle is 0.27m, the diameter of the nozzle is Φ=40mm, the diameter of the auxiliary nozzle is Φ=15mm, there are 8 auxiliary nozzles, and the outlet of the auxiliary nozzle is distributed in one concentric with the outlet of the main nozzle on the circle.

[0049] The outlet pressure of the injection device is 0.1--3Mpa, and the fluid turbulence intensity of the gas: 2.7m 2 / s 2 ; The injection time is 0.7h, and the gas temperature at the tuyere is 950°C.

[0050] Compared with the existing single-tube spray gun with the same length and diameter, 1) under the same injection pressure, the injection length is increased by 8.2%; 2) the impact depth of the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com