A method for controlling hydrogen sulfide in coal seams by dynamic alkali injection

A hydrogen sulfide and alkali injection technology, which is applied in earth-moving drilling, mining equipment, mining equipment, etc., can solve the problems of lack of scientific theoretical basis for process parameters, unsatisfactory effect, and increase of air volume on working face, so as to improve underground operations. Environment, low cost of treatment, and effect of reducing atmospheric emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

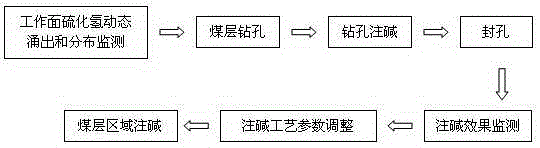

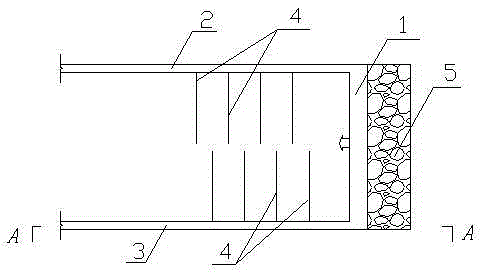

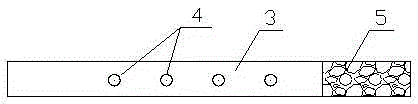

[0031] A method for dynamic alkali injection to control coal seam hydrogen sulfide, such as figure 1 , 2 shown, follow the steps below:

[0032] (1) Monitor the dynamic emission law of hydrogen sulfide in coal mining face:

[0033] For a typical mine where hydrogen sulfide gushes out, during the process of excavating the coal seam, when the hydrogen sulfide detector is used to monitor the coal cutting in a certain area of the coal seam in real time, the concentration of hydrogen sulfide gushing out from the coal mining face 1 is 30ppm (0.003%) The air volume of wind lane 3 is 1100m 3 / min, it can be determined that the hydrogen sulfide outflow is 0.033m 3 / min, according to the coal mining speed, cutting depth and mining height, the coal output per unit time is determined to be 4.3t / min, and the hydrogen sulfide ton coal content is finally determined to be 0.00766m 3 / t, converted into a molar content of 0.342mol / t;

[0034] (2) Parameter design of coal seam drilling fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com