UV curable silicone release agent

A technology of silicone and release agent, applied in the direction of coating, etc., can solve the problems of low yield, complicated reaction process, poor surface curing, etc., to achieve improved surface curing, good release effect, and good surface curing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

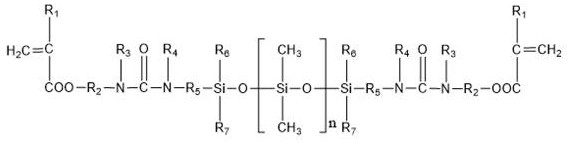

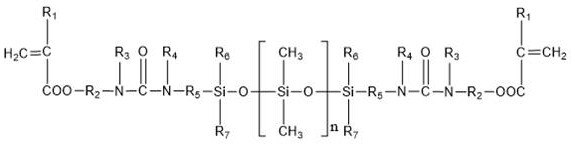

[0040]The UV-curable silicone release agent (photoswitchable silicone release agent) of the present invention has good storage stability at room temperature, and will not be cured by moisture when exposed to the air, but UV light can quickly cause moisture Curing and UV curing belong to the UV / moisture dual-curing system. Different from the ordinary UV / moisture dual-curing system, the photoswitchable silicone release agent described in the present invention will only cause moisture after UV irradiation. solidified.

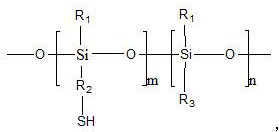

[0041] In the UV-curable silicone release agent described in the present invention, the moisture curing catalyst employed therein may be a synthetic (meth)acryloyloxyalkylureido double-terminated polydimethylsiloxane, wherein Among the catalyst catalysts used:

[0042] Commonly used organotin compounds include: dibutyltin dilaurate, dibutyltin diacetate, dibutyltin diethylhexanoate, dibutyltin dioctoate, dibutyltin dimethylmaleate, dibutyltin maleate, dioctyltin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com