Method for recovery of condensed alcohol ether in epoxypropane wastewater

A technology of propylene oxide and resource utilization, which is applied in chemical instruments and methods, organic chemistry, hydrolysis preparation, etc., can solve the problems of high processing cost and waste of resources, and achieve the effects of clear environment, extended service life and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

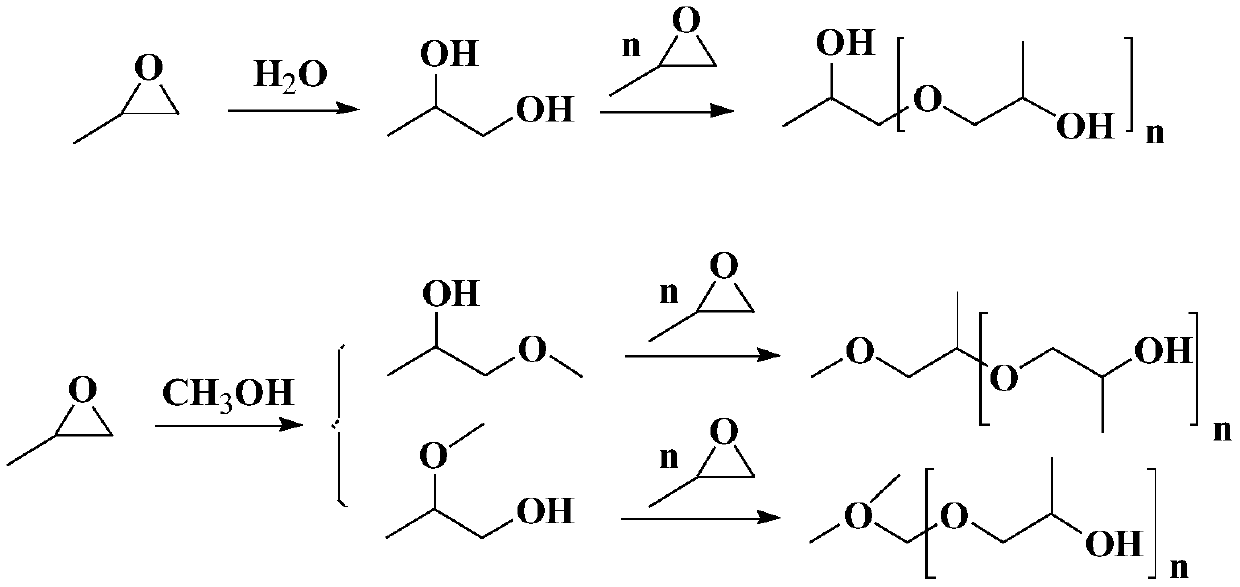

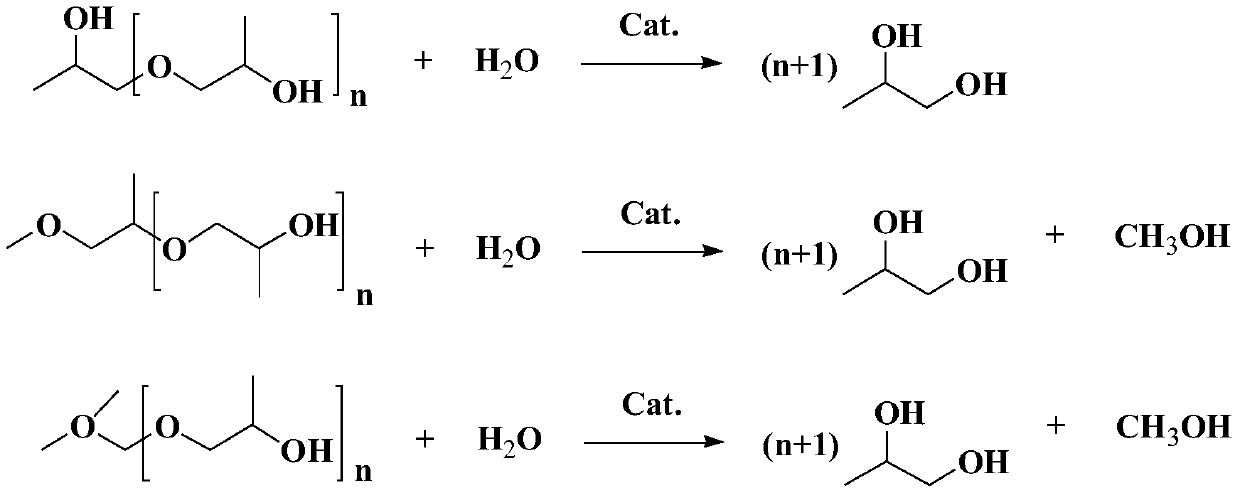

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 modified molecular sieve catalyst

[0023] (1) Preparation of Fe-Ni modified SAPO-34 catalyst

[0024] Fe-Ni modified SAPO-34 catalyst was prepared by co-impregnation method, weighed a certain amount of iron nitrate solid and nickel nitrate solid and dissolved in an appropriate amount of deionized water, slowly added SAPO-34 molecular sieve powder and stirred, stirred evenly and then stood Immerse for 12 hours; then dry at 110°C for 12 hours, and roast at 550°C for 3 hours to obtain the (Fe-Ni) / SAPO-34 catalyst, which is subjected to hydrolysis of condensation alcohol ethers of wastewater after tableting and sieving. Among them, the Fe loading is 1.5wt%, and the Ni loading is 1.5wt%.

[0025] (2) Preparation of Ag-Pd modified HZSM-5 catalyst

[0026] The Ag-Pd modified HZSM-5 catalyst was prepared by the co-impregnation method. A certain amount of silver nitrate solid and palladium chloride solid was weighed and dissolved in an appropri...

Embodiment 2

[0033] Resource utilization of condensed alcohol ether in the waste water of embodiment 2

[0034] (1) fill 3wt% (Fe-Ni) / SAPO-34 catalyzer in fixed-bed reactor, make the propylene oxide waste water after desalting with 80h -1 Pump it into the reactor, and carry out the hydrolysis reaction at 1.0MPa and 180°C. The yield of propylene glycol in the analysis output was 74%, and the yield of methanol was 81%.

[0035] (2) fill 0.1wt% (Ag-Pd) / HZSM-5 catalyzer in the fixed-bed reactor, make the propylene oxide waste water after desalting with 120h -1 Pump it into the reactor, and carry out the hydrolysis reaction at 1.5MPa and 160°C. The yield of propylene glycol in the analysis discharge was 70%, and the yield of methanol was 75%.

[0036] (3) fill 6wt% (Cu-Pt) / MCM-22 catalyzer in fixed-bed reactor, make the propylene oxide waste water after desalting with 100h -1 Pump it into the reactor, and carry out the hydrolysis reaction at 1.2MPa and 150°C. The yield of propylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com