Preparation method of nanometer hydroxyapatite powder

A nano-hydroxyapatite, hydroxyapatite technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds and other directions, can solve the problem of uneven particle size distribution, large particle size of hydroxyapatite powder, easy to appear Agglomeration and other problems, to achieve the effect of inhibiting aggregation and growth, eliminating local inhomogeneity, and increasing nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

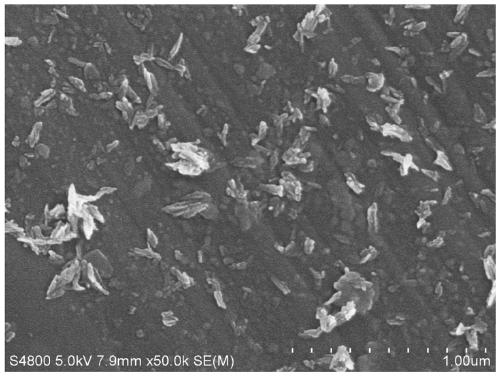

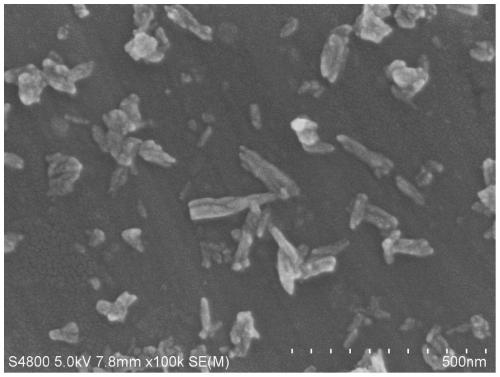

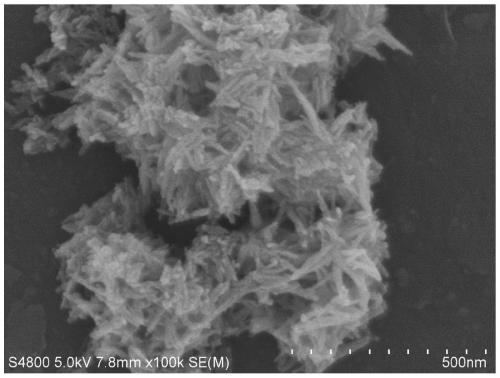

Image

Examples

Embodiment 1

[0031] A preparation method of nano-hydroxyapatite powder, comprising the following steps:

[0032] 1) preparing 160ml of phosphate ion solution with a concentration of 0.12mol / L, and adjusting the pH value of the phosphate ion solution to 10 with concentrated ammonia;

[0033] 2) Prepare 40ml of calcium ion solution with a concentration of 0.2004mol / L, and adjust the pH value of the calcium ion solution to 10 with concentrated ammonia water;

[0034] 3) The calcium ion solution is sprayed into the phosphate ion solution placed in an ultrasonic environment at a flow rate of 2ml / min after being atomized by ultrasonic spray, wherein, the ultrasonic spray atomization time of the calcium ion solution is 20min, and after all the calcium ion solution After the spraying is completed, the mixed solution is left to stand for half an hour to obtain hydroxyapatite precipitation;

[0035] 4) Pour the hydroxyapatite precipitate into a centrifuge tube, use ultrapure water and absolute etha...

Embodiment 2

[0037] A preparation method of nano-hydroxyapatite powder, comprising the following steps:

[0038] 1) Prepare 160ml of phosphate ion solution with a concentration of 0.12mol / L, and adjust the pH value of the phosphate ion solution to 10 with concentrated ammonia;

[0039] 2) Prepare 40ml of calcium ion solution with a concentration of 0.2004mol / L, and adjust the pH value of the calcium ion solution to 10 with concentrated ammonia water;

[0040] 3) The calcium ion solution is sprayed into the phosphate ion solution placed in an ultrasonic environment at a flow rate of 8ml / min after being atomized by ultrasonic spray, wherein, the ultrasonic spray atomization time of the calcium ion solution is 5min, and after all the calcium ion solution After the spraying is completed, the mixed solution is left to stand for half an hour to obtain hydroxyapatite precipitation;

[0041] 4) Pour the hydroxyapatite precipitate into a centrifuge tube, use ultrapure water and absolute ethanol an...

Embodiment 3

[0043] A preparation method of nano-hydroxyapatite powder, comprising the following steps:

[0044] 1) Prepare 160ml of phosphate ion solution with a concentration of 0.3mol / L, and adjust the pH value of the phosphate ion solution to 10 with concentrated ammonia;

[0045] 2) Prepare 40ml of calcium ion solution with a concentration of 0.501mol / L, and adjust the pH value of the calcium ion solution to 10 with concentrated ammonia water;

[0046] 3) The calcium ion solution is sprayed into the phosphate ion solution placed in an ultrasonic environment at a flow rate of 8ml / min after being atomized by ultrasonic spray, wherein, the ultrasonic spray atomization time of the calcium ion solution is 5min, and after all the calcium ion solution After the spraying is completed, the mixed solution is left to stand for half an hour to obtain hydroxyapatite precipitation;

[0047]4) Pour the hydroxyapatite precipitate into a centrifuge tube, use ultrapure water and absolute ethanol and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com