Novel processing device and method for enhanced absorption of VOCs (volatile organic matter)

A new technology with enhanced absorption, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of affecting the surrounding environment, irritation, carcinogenicity, etc., and achieve the effects of low cost, small droplets, and high humidification intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

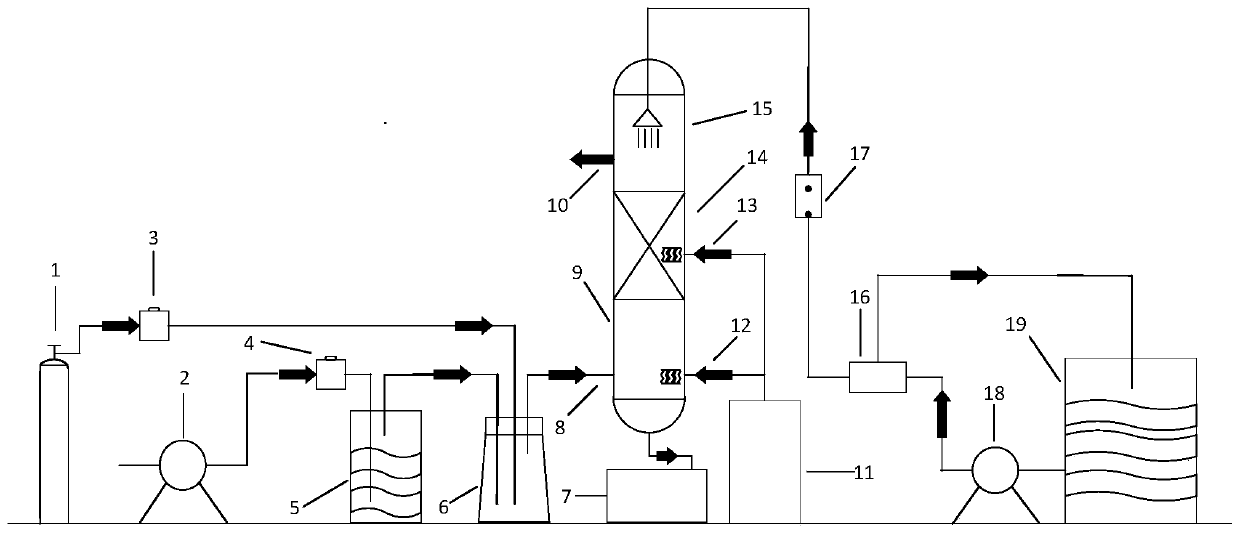

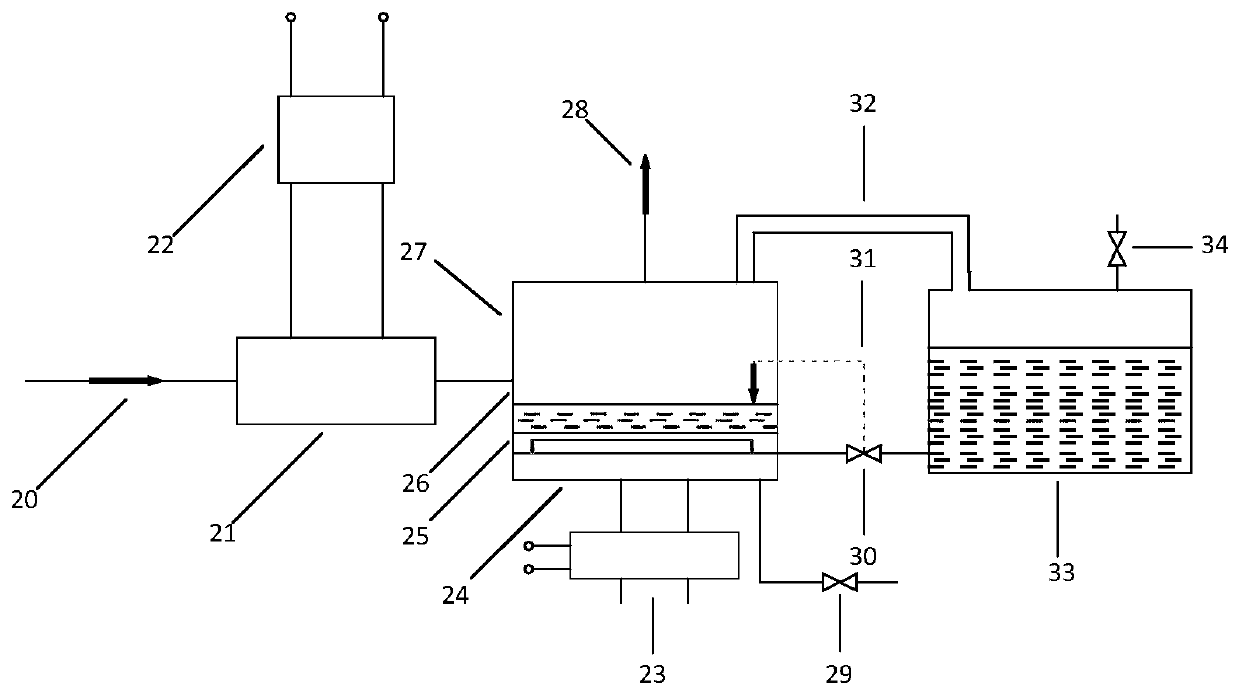

[0051] In order to highlight the obvious advantages of the ultrasonic atomization effect, a common absorption tower is added for comparison. In this implementation case, the figure 2 The experimental flow chart.

[0052] The parameters of the ultrasonic atomizer device are: the inner diameter of the humidifying tank 27 is 270 mm, the height is 280 mm, the height of the ultrasonic humidifying high-frequency oscillator 24 is 50 mm, the liquid level in the humidifying tank 27 is 35 mm, the inlet gas temperature is 289.6K, and the inlet is relatively The humidity is 43%, the flow rate is 15.71L / min, the pressure of the humidifying tank 27 is 196kPa, there are 251 transducers, and the power is 35W; Volume 450mL / h.

[0053] The Raschig ring packing layer 14 with a packing layer height of 3 cm is put into the absorption tower. Afterwards, the methanol solution with a mass concentration of 15% is placed in the gaseous pollutant storage bottle 5, and the water pump 18 is opened aft...

Embodiment 2

[0059] The Raschig ring packing layer 14 with a packing layer height of 4 cm is put into the absorption tower. Afterwards, the methanol solution with a mass concentration of 15% is placed in the gaseous pollutant storage bottle 5, and the water pump 18 is opened after mixing evenly, and the water in the pool 19 is injected into the absorption tower through the tee 16 and the liquid flow meter 17, and the liquid Flow meter 17 is adjusted to 45L / h, 59.5L / h, 72L / h, 90L / h, 110L / h respectively.

[0060] Open the nitrogen in the inert gas cylinder 1 and feed it into the gas path through the inert gas flowmeter 3, and the inert gas flowmeter (3) is adjusted to 60L / h. After waiting for the inert gas to be purged in the absorption tower 9, start the air pump 2, The methanol gas in the gaseous pollutant storage bottle 5 is injected into the buffer bottle 6 through the gas flowmeter 4 to mix with nitrogen, and the gas flowmeter 4 is adjusted to 15L / h, 17L / h, 18L / h, 20L / h, 22L / h, the rat...

Embodiment 3

[0065] The Raschig ring packing layer 14 with packing layer height of 5 cm is put into the absorption tower. Afterwards, the methanol solution with a mass concentration of 15% is placed in the gaseous pollutant storage bottle 5, and the water pump 18 is opened after mixing evenly, and the water in the pool 19 is injected into the absorption tower through the tee 16 and the liquid flow meter 17, and the liquid Flow meter 17 is adjusted to 45L / h, 59.5L / h, 72L / h, 90L / h, 110L / h respectively.

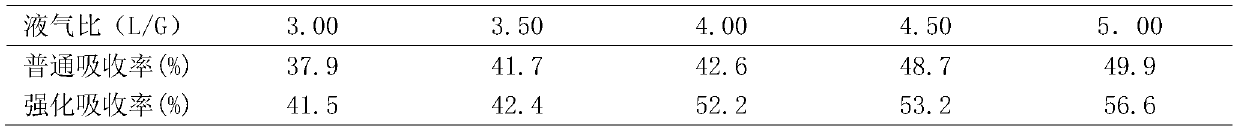

[0066] Open the nitrogen in the inert gas cylinder 1 and pass it into the gas path through the inert gas flow meter 3, and the inert gas flow meter 3 is adjusted to 60L / h. The methanol gas in the pollutant storage bottle 5 is pumped into the buffer bottle 6 through the gas flowmeter 4 and mixed with nitrogen, and the gas flowmeter 4 is adjusted to 15L / h, 17L / h, 18L / h, 20L / h, 22L / h h, the ratio of liquid flow to gas flow at this time is 3.00, 3.50, 4.00, 4.50, 5.00. After the two gases are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com