Oxygen production system based on high-temperature oxygen permeation membranes

An oxygen production system and oxygen-permeable membrane technology, applied in the fields of oxygen production, oxygen/ozone/oxide/hydroxide, membrane technology, etc., can solve the problems of low efficiency, high power consumption, unenvironmental protection, etc., and reduce the thickness , the effect of improving oxygen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

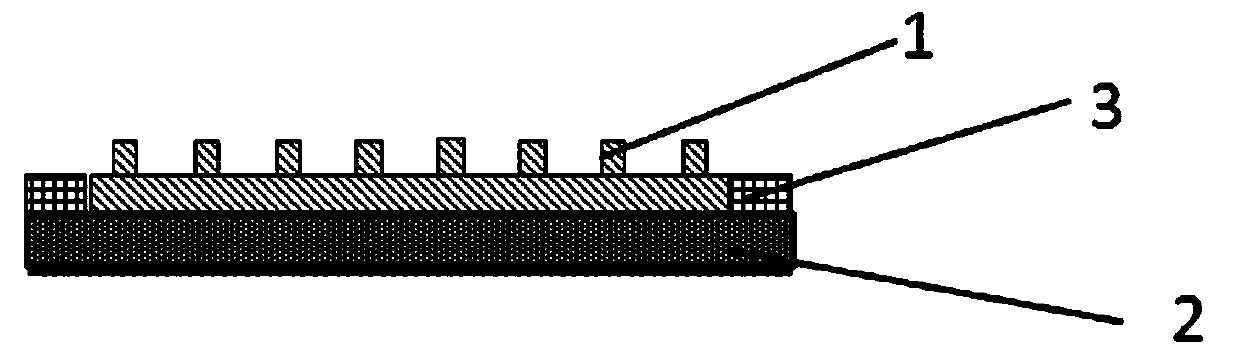

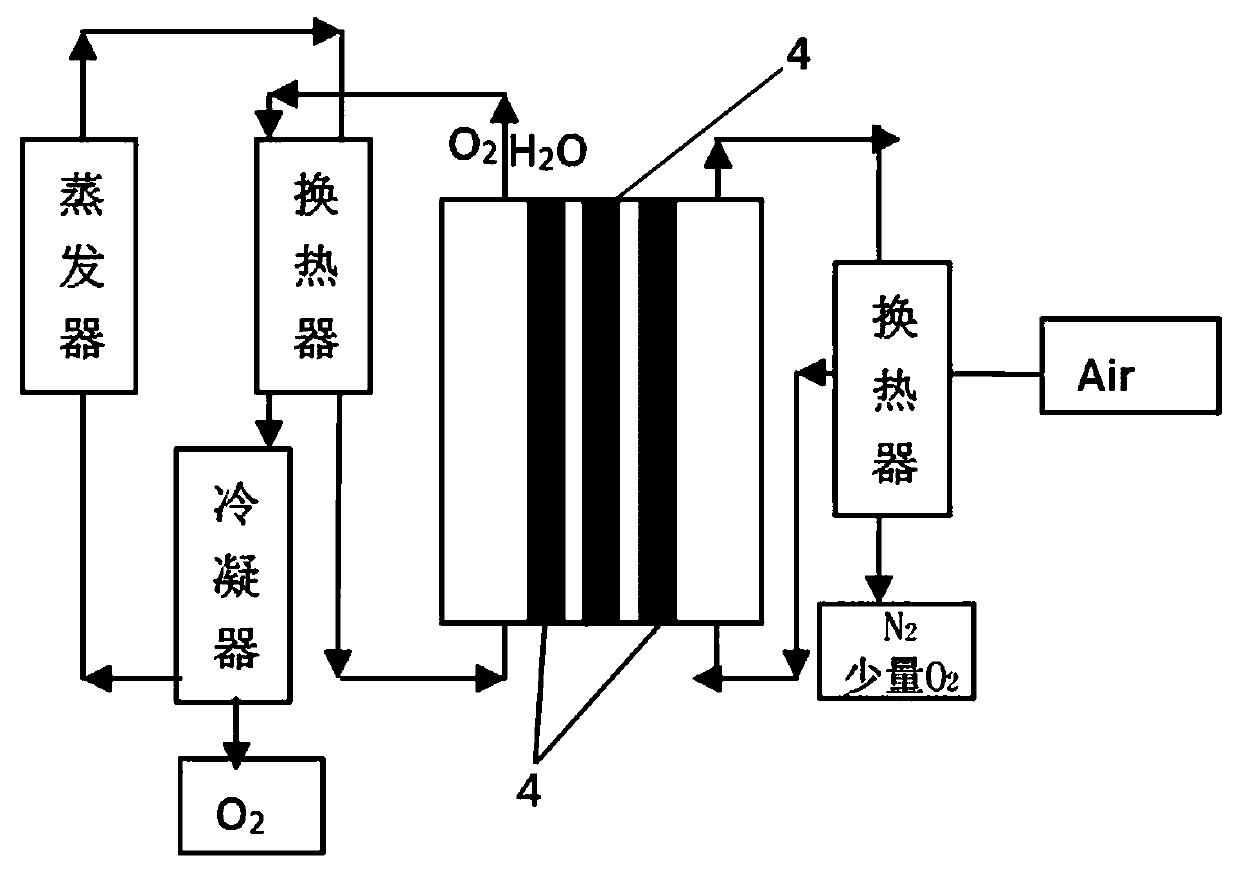

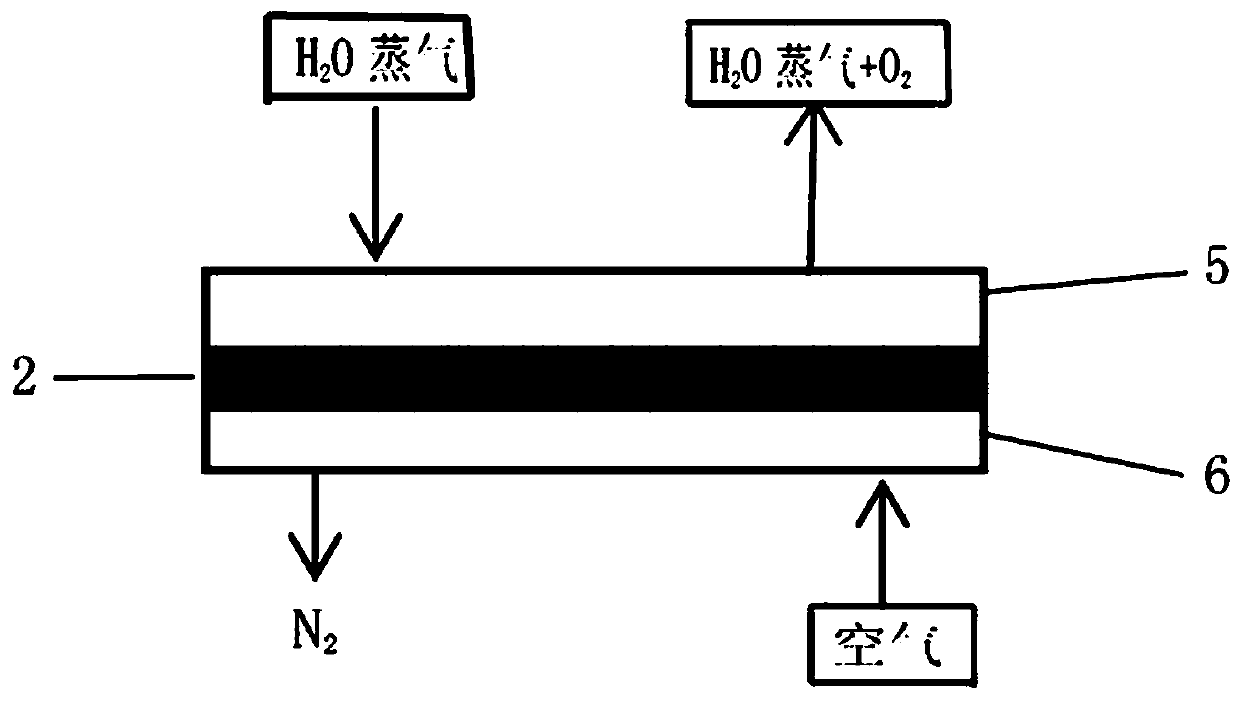

[0023] Such as figure 2 As shown, the oxygen-generating system based on the high-temperature oxygen-permeable membrane includes the oxygen-permeable membrane group 4, and the oxygen-permeable membrane group is composed of several stacked oxygen-permeable membrane repeating units. Such as image 3 As shown, the ceramic oxygen-permeable membrane in the repeating unit of the oxygen-permeable membrane divides the cavity of the repeating unit into an oxygen-making side 5 and an air side 6; the air side is provided with an air inlet and a nitrogen gas outlet; the oxygen-making side An oxygen outlet is provided; the feature is: the oxygen production side is provided with a water vapor inlet, the oxygen outlet on the oxygen production side is connected to a condenser, and the condenser is provided with a condensed water drain and an oxygen outlet.

[0024] The oxygen permeable membrane is dense at high temperature, and can conduct oxygen ions to form directional migration. It can be...

Embodiment 2

[0030] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0031] This example is based on 50 pieces of 100*100cm LSCF oxygen-permeable membranes. The flow field adopts the counterflow method, the air side adopts the fully sealed method, and the repeating units are superimposed. The effective area of a single sheet is 64cm 2 , the working temperature is 750°C, and the oxygen production can reach 2.5 L / min. At this time, it is a mixed conductor film, and the oxygen-permeable film is equivalent to the internal short circuit of the battery and does not consume electric energy. However, the gas circulation pump needs to consume externally provided electric energy. In the case of small-scale oxygen production in this embodiment, the energy consumption is about 1.2 kWh / m 3 Oxygen, higher than traditional air separation methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com