A general multi-mode smart adsorption drying method with low energy consumption for compressed air preparation

A compressed air, adsorption and drying technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high wet load of adsorption cylinder, sharp increase of system operation resistance, large regeneration gas consumption, etc., to achieve long-term guarantee Stable work, reduce replacement costs, and ensure long-term smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

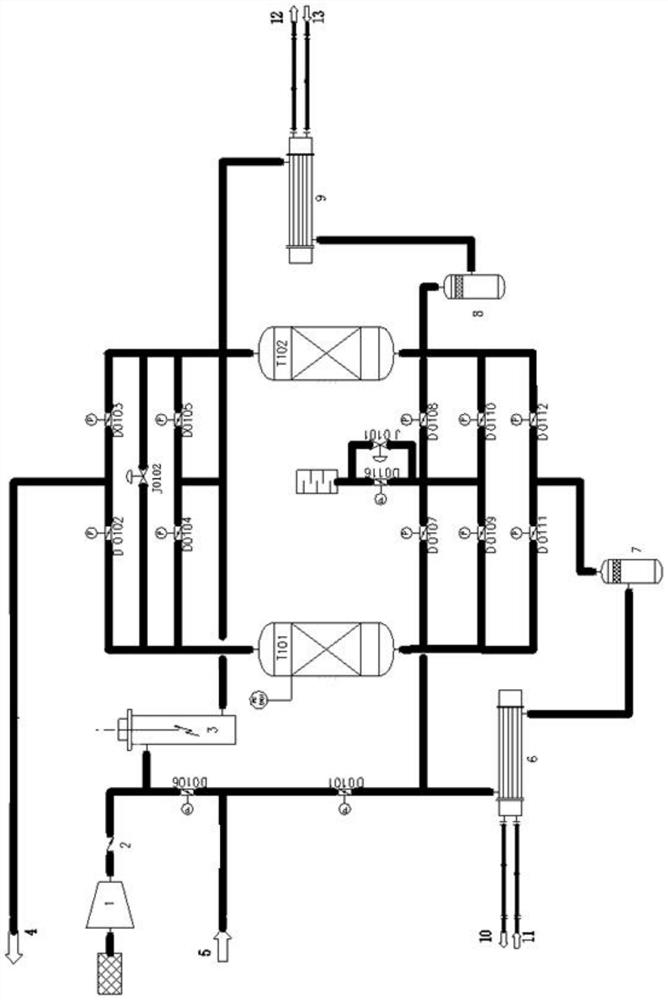

[0060] Specific embodiments of the present invention such as figure 1 shown. The overall structure adopts double adsorption cylinder structure, one adsorption cylinder regenerates and the other adsorption cylinder absorbs. In order to clarify the basic process, they are named adsorption cylinder A and adsorption cylinder B respectively. The two adsorption cylinders alternately adsorb and regenerate, and the process adopts a symmetrical design structure as a whole. Taking the regeneration of adsorption cylinder A and the adsorption of adsorption cylinder B as an example, the process operation is explained. The whole process is divided into: 1) Compressed air waste heat heating stage; 2) Pressure release stage; 3) Blast deep heating stage; 4) Circular blowing cooling stage. After the regeneration of the adsorption cylinder A is completed, the work flow of the two adsorption cylinders is interchanged, and it is an overall working cycle until the next interchange. The above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com