Metal recycling and feeding method

A feeding method and technology of recycling materials, applied in lighting and heating equipment, furnace types, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

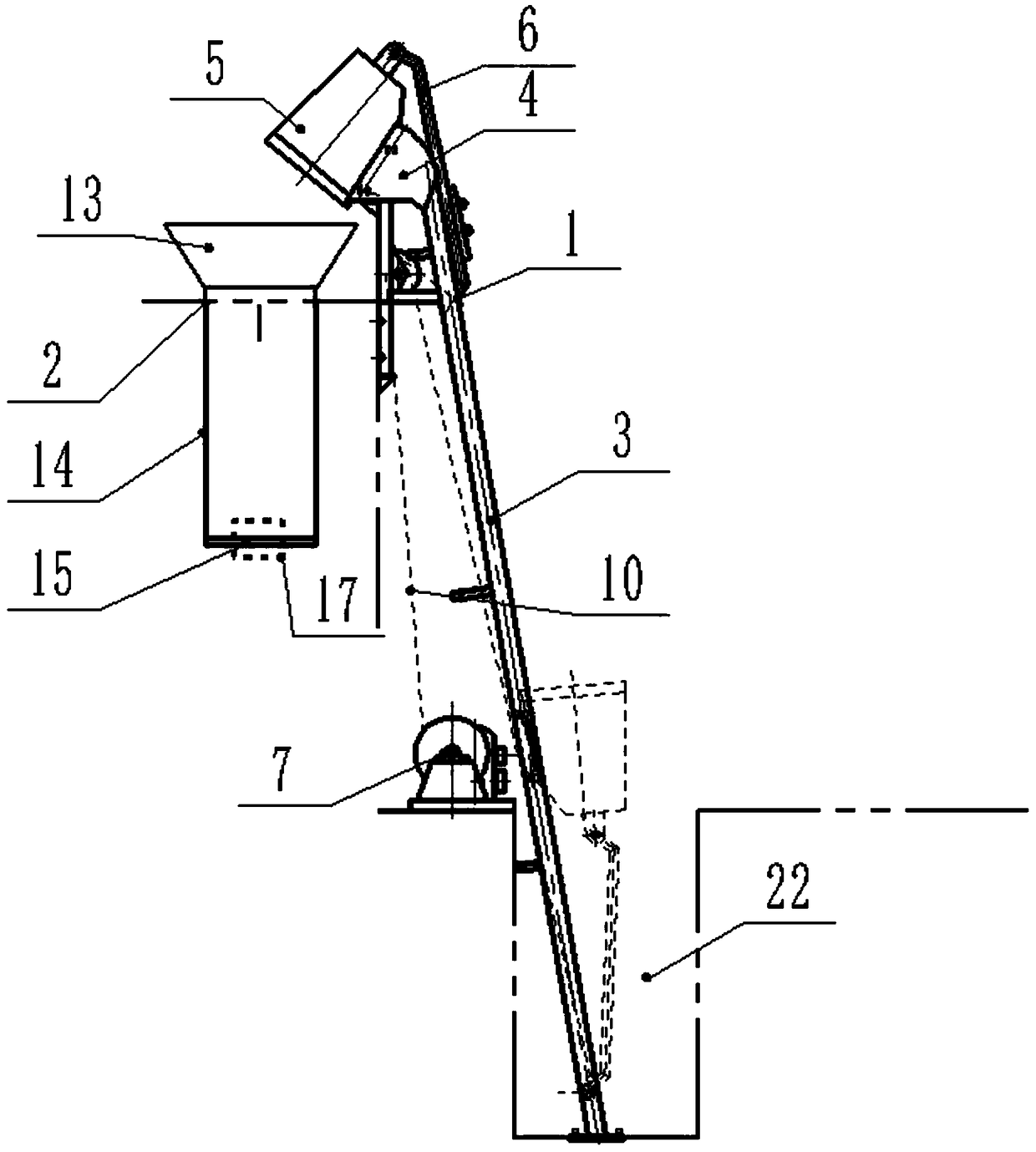

[0038] Such as Figure 1-8 Shown, a kind of metal recovery feeding method of the present invention comprises steps:

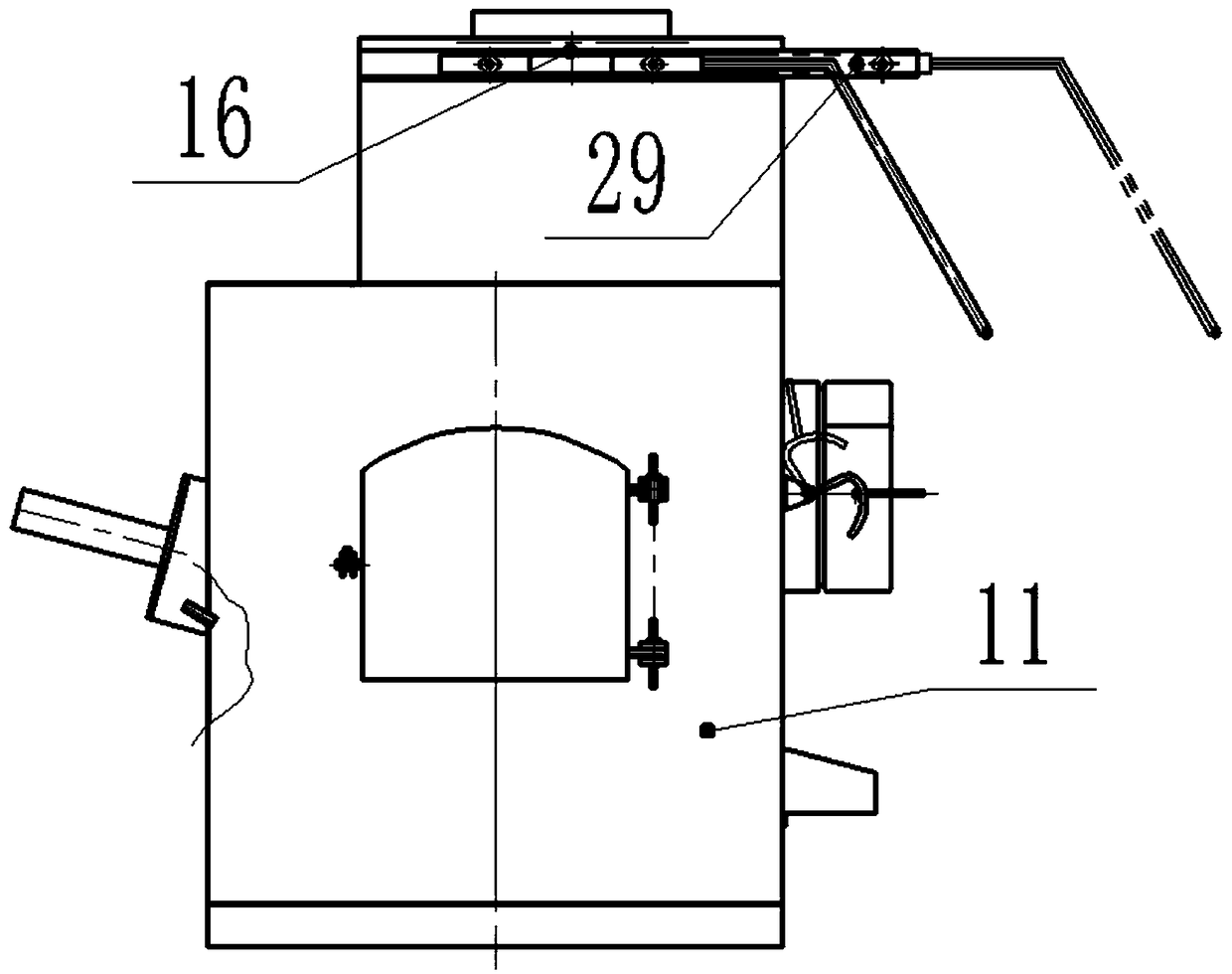

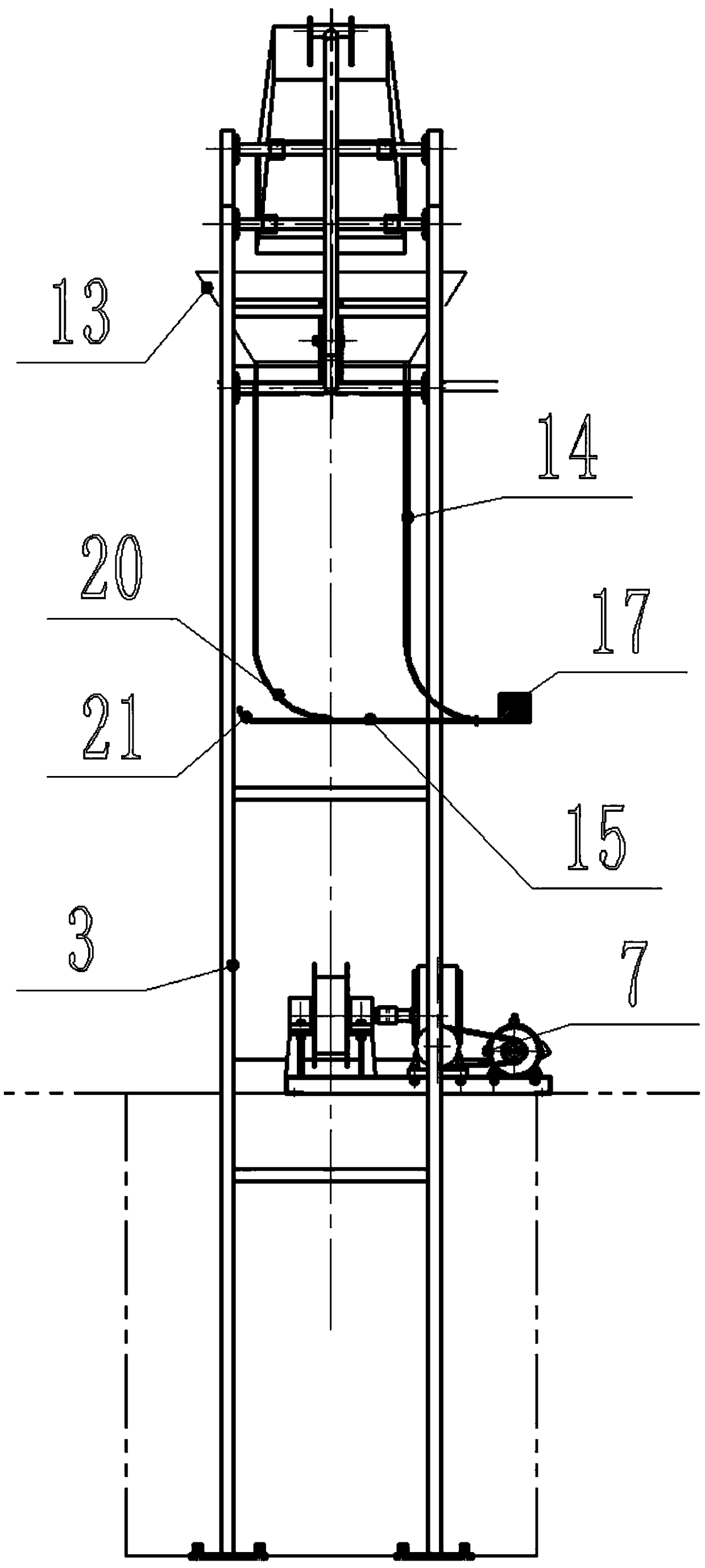

[0039]Step 1, setting a feeding device 2 on the feeding furnace mouth 16 on the melting chamber 18; the feeding device 2 includes a feeding hopper 13, a material guide cylinder 14 and a material guide plate 15, and the feeding hopper 13 is arranged on the feeding furnace On the port 16, the upper end of the material guide cylinder 14 is connected to the lower port of the lower hopper 13, the outer end of the material guide plate 15 is hinged on the side wall of the lower port of the material guide cylinder 14, and the outer end of the material guide plate 15 There is a counterweight 17 on it;

[0040] Step 2. Install a feeding device 1 on the body of furnace 11; the feeding device 1 includes a feeding rail frame 3, an overturning frame 4, a loading hopper 5, a push rod frame 6 and a hoist 7, and the feeding rail frame 3 Erected on the furnace body 11, the tip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com