Push-condensing integrated high-resolution space optical load ultra-light carbon fiber truss support structure

A space optics and support structure technology, applied in optics, optical components, installation, etc., can solve the problems of poor structural strength, rigidity index, difficult grinding, difficult fine-tuning, etc., and achieve simple processing technology, simple assembly process, and guaranteed position relationship effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

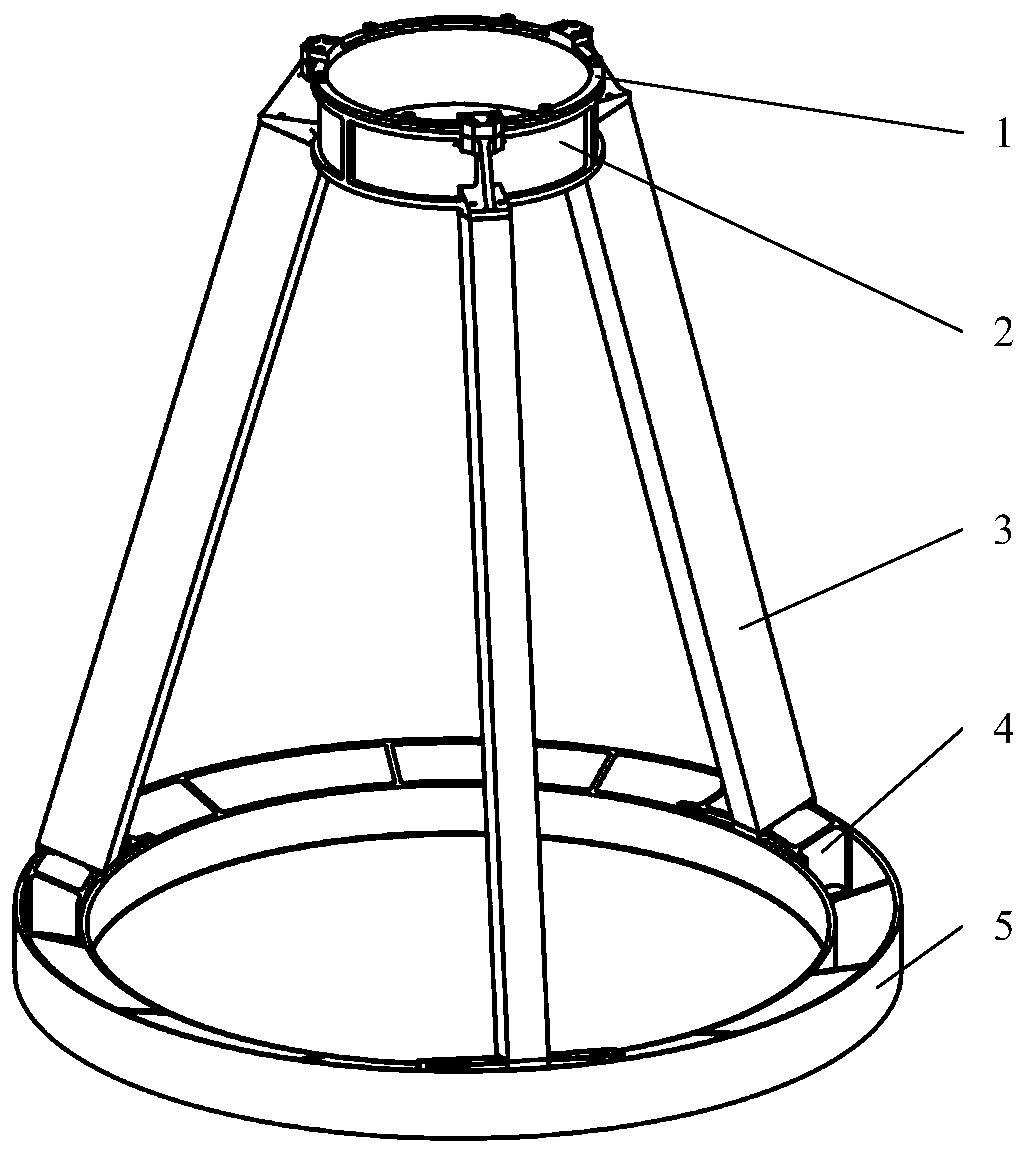

[0036] The ultra-light carbon fiber truss support structure of the push-condensation integrated high-resolution space optical load of the present invention is as follows: figure 1 As shown, it includes an adjusting gasket 1, a secondary mirror chamber 2, a truss rod 3, a metal embedded part 4, and a support ring 5.

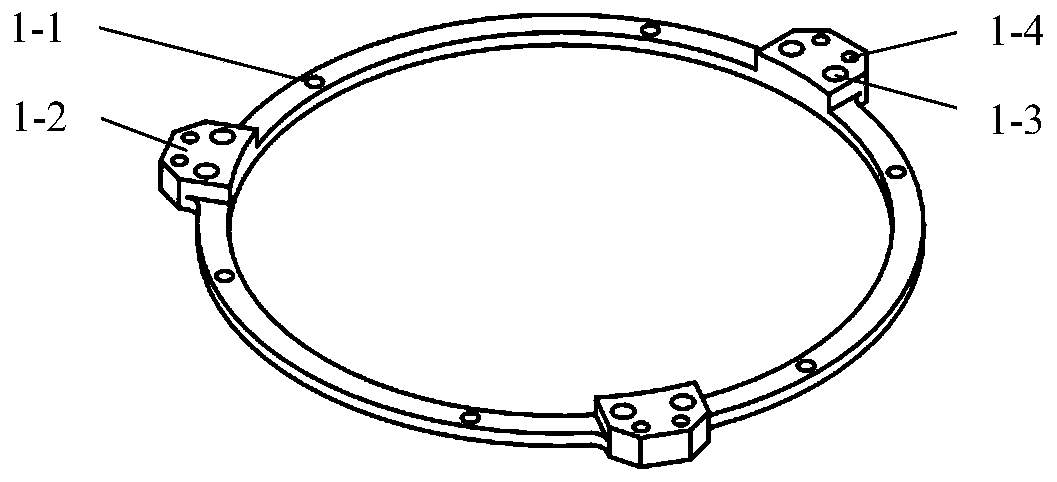

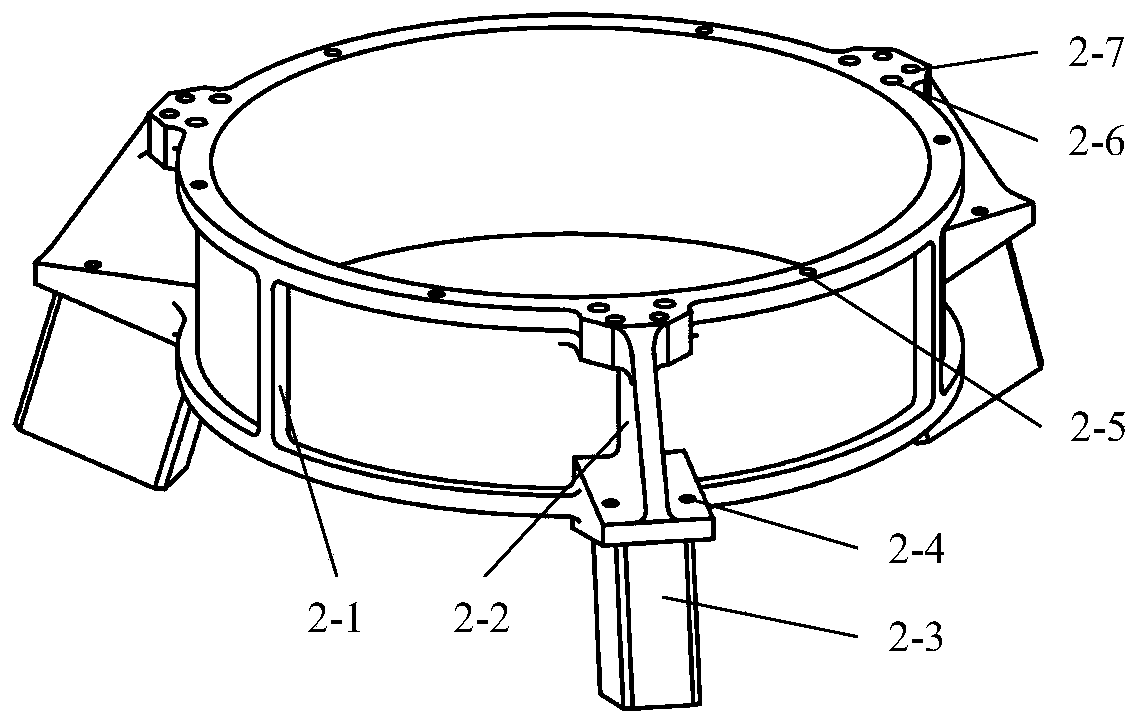

[0037] The adjusting gasket 1 is made of titanium alloy material, such as figure 2 As shown, 6 first screw through holes 1-1 are evenly distributed on the circumference, and 6 second threaded holes 2-5 are evenly distributed on the corresponding positions on the upper end surface of the secondary mirror chamber 2, as Figure 3aAs shown, the adjusting gasket 1 is connected with the secondary mirror chamber 2 by screws. Three first bosses 1-2 are evenly distributed on the upper end of the adjustment spacer 1, which is the installation plane of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com