Aeroengine single cantilever pipeline pipe nipple portion verticality measuring device

A technology for aero-engines and measuring devices, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of unqualified measurement results, time-consuming and labor-intensive operation, and difficult to pass, so as to reduce the contact area and weight , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

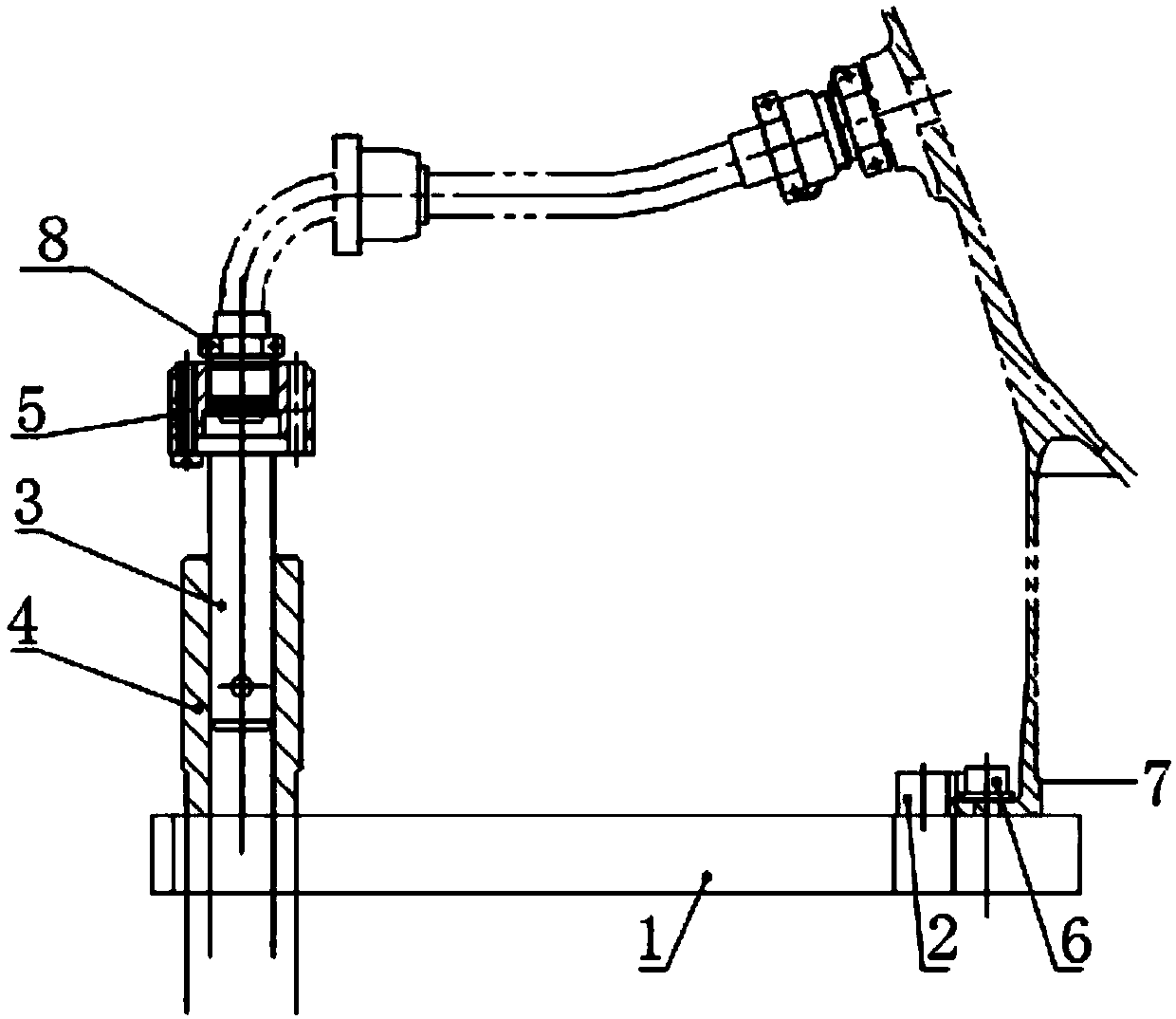

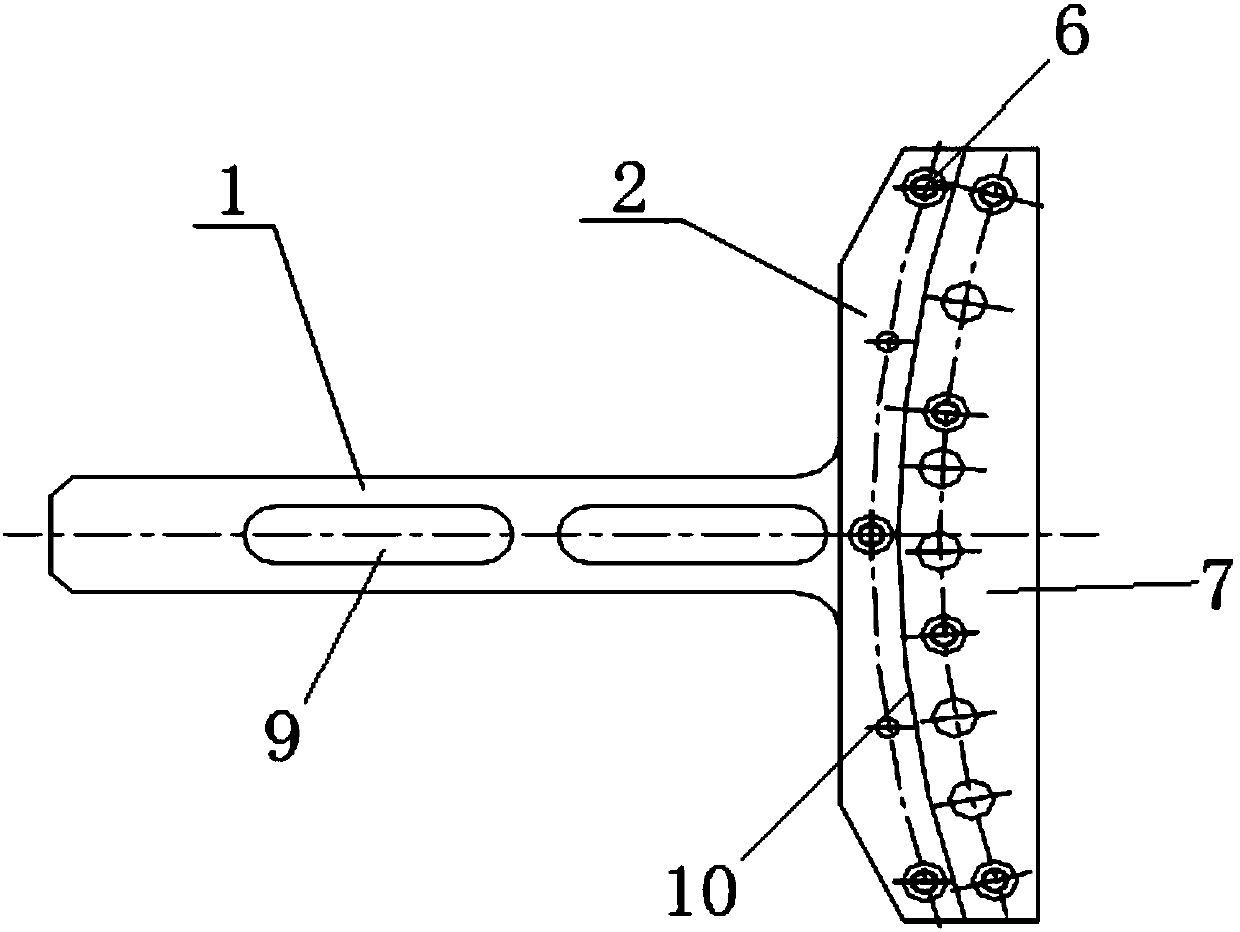

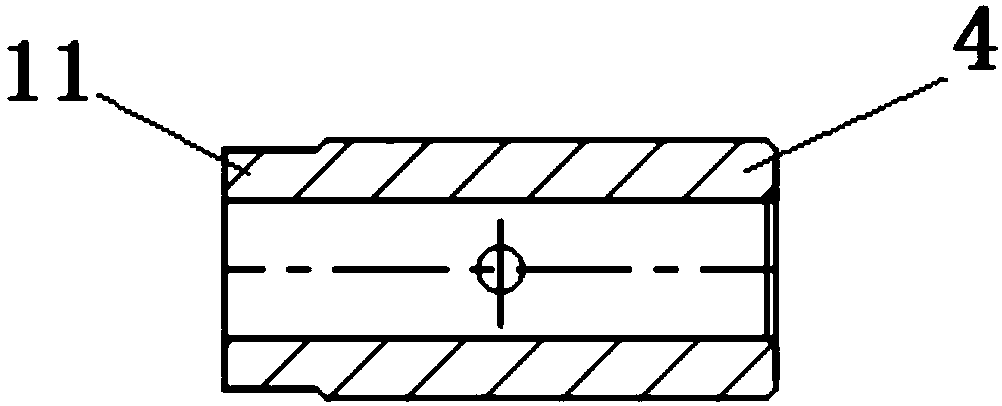

[0021] The invention provides a verticality measuring device for the nozzle of a single cantilever pipeline of an aero-engine, such as figure 1 As shown, it includes a positioning plate 1 and a positioning block 2. The positioning block 2 is fixedly connected to the positioning plate 1 through screws and cylindrical pins; It is used to position the positioning plate 1 directly below the nozzle part 8 of the single cantilever pipeline pipe of the aero-engine; the positioning plate 1 is also provided with a bushing 4, and the bushing 4 is attached to the positioning plate 1, and the bushing 4 There is a positioning shaft 3 in the inner sleeve, and the sleeve 4 and the positioning shaft 3 are in a sliding fit, and the fit gap is less than 0.01mm; the positioning shaft 3 is connected to the pipe joint part 8 through a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com