Construction method for quickly assembling the transverse block of a bridge substructure

A construction method and block technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult control of hoisting elevation and axis deviation, slow filling material strength, and low positioning accuracy, so as to improve productivity Position accuracy and stability, improving cable-staying conditions, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

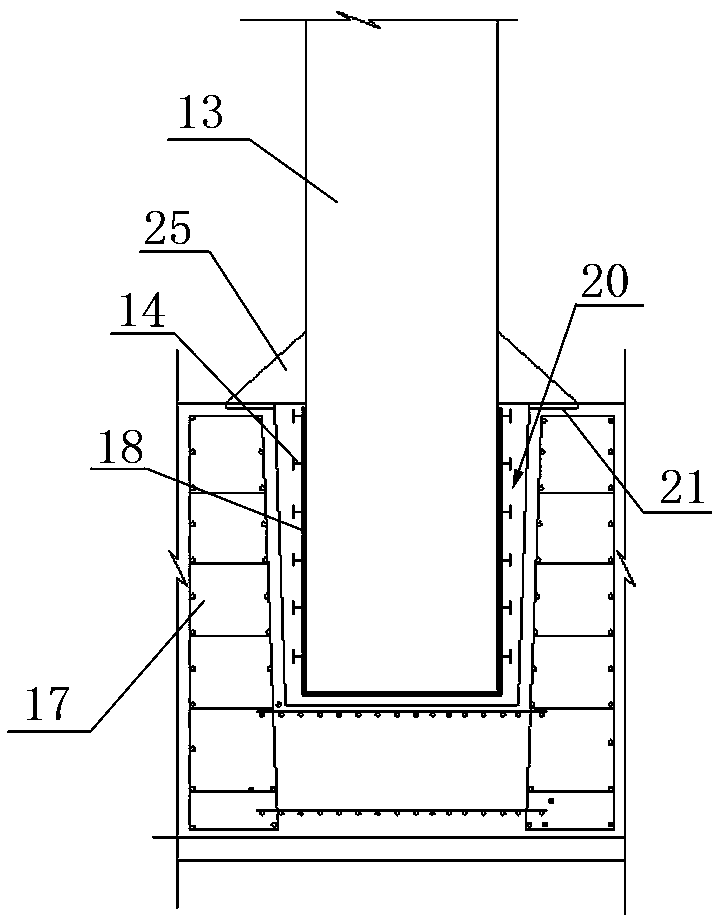

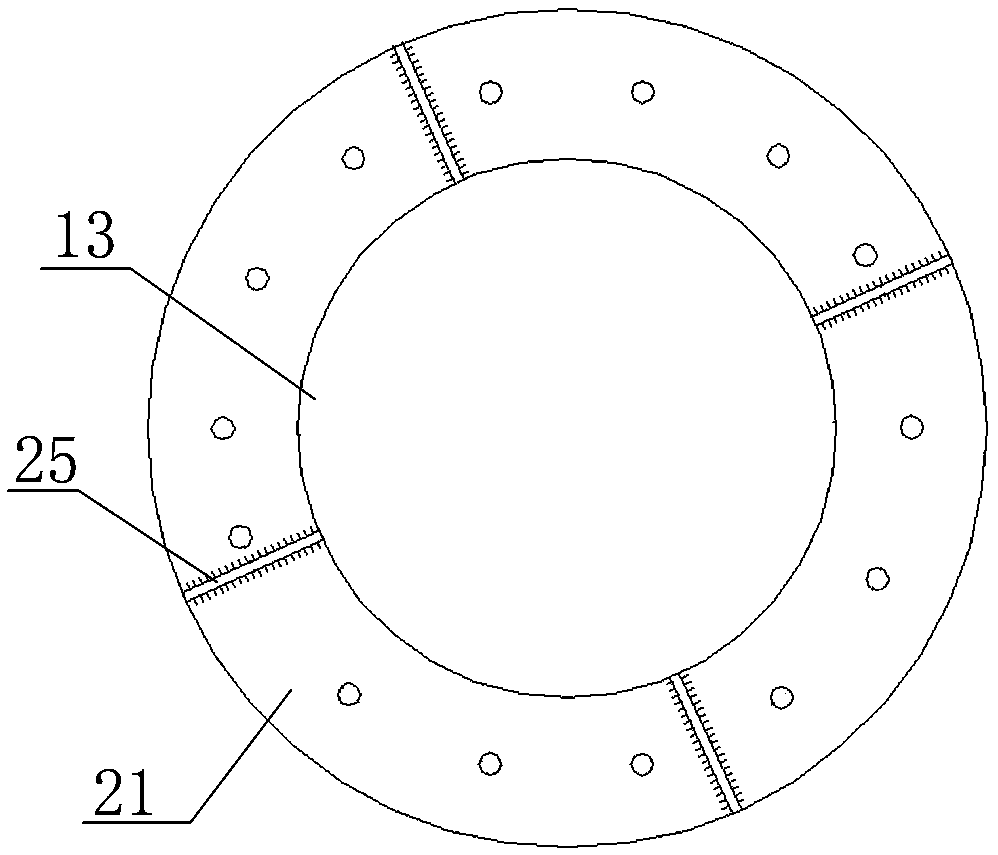

[0073] In this embodiment, the prefabricated pier column cover beam 13 is integrally prefabricated in the form of a cover beam connected to a cylindrical pier; the pier column foundation 17 is in the form of a cast-in-place enlarged foundation, and the top of the expanded foundation is provided with a cup mouth 20, and the prefabricated pier column cover beam 13 The pier column extends 1.6m into the inside of the cup mouth 20, and the prefabricated pier column cover beam 13 and the pier column foundation 17 are connected by setting a wet joint in the form of a cup mouth.

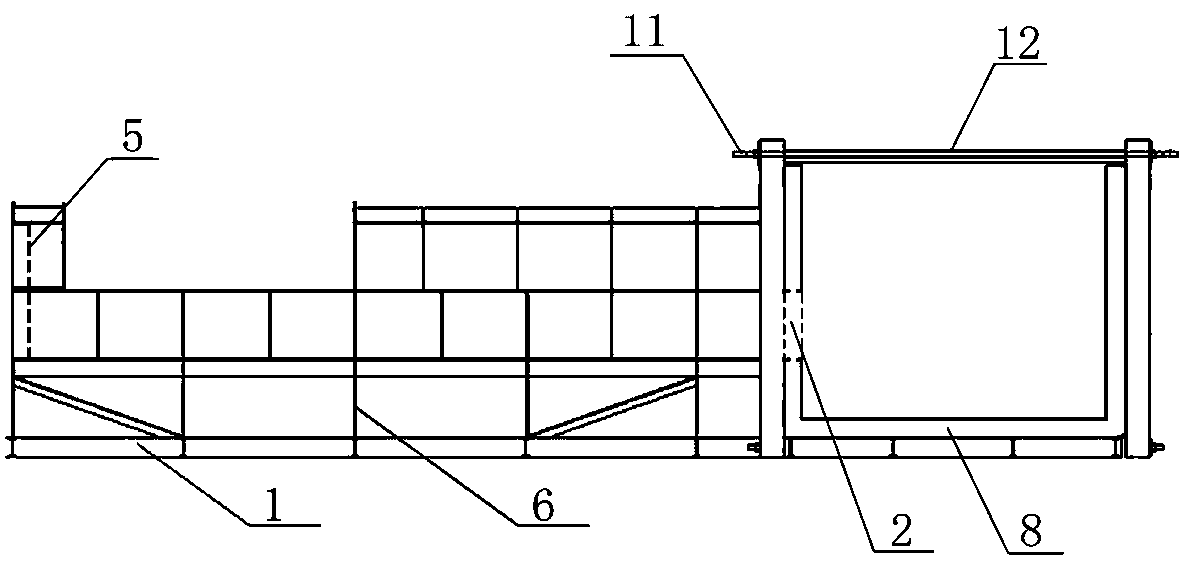

[0074] Such as Figure 1-13 As shown, the construction method of the rapid assembly of horizontal blocks of the bridge substructure includes the following steps.

[0075] Step 1. Integrated construction of the prefabricated pier column cover beam 13; wherein, the lower part of the pier column of the prefabricated pier column cover beam 13 is provided with a steel plate hoop 18, and the outer surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com